3D mobile phone back cover and molding process thereof

A mobile phone back cover, 3D technology, applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems that the battery cannot be charged wirelessly, the back cover of the mobile phone is hot, dry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

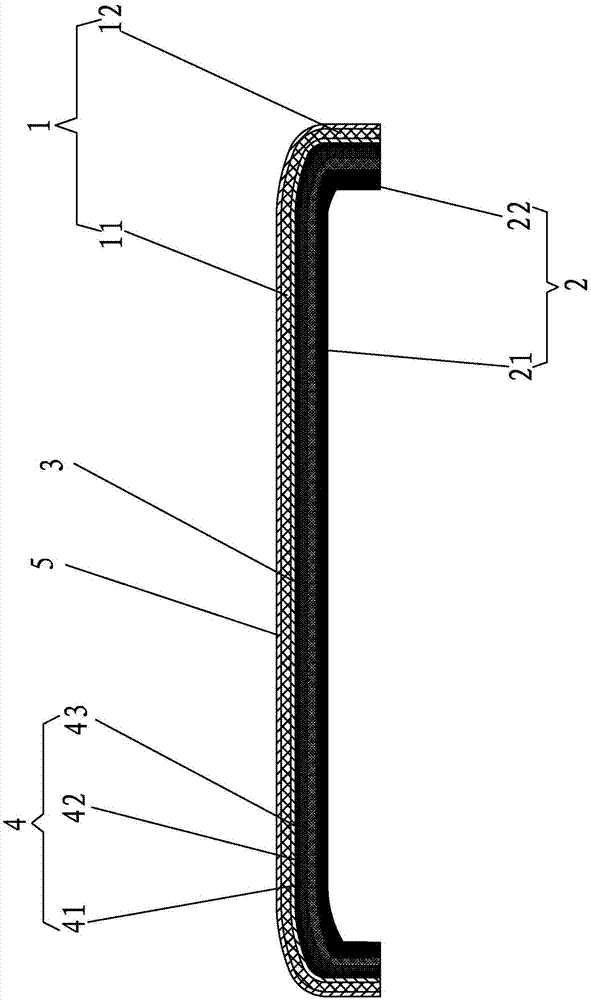

[0024] A 3D mobile phone back cover of the present invention, such as figure 1 As shown, it includes a body with a back plate that fits the back of the mobile phone and a side frame that fits the side wall of the mobile phone,

[0025] The body includes a glass back cover 1 and a PET film 2. The glass back cover 1 has a flat plate part 11 that matches the size of the back plate and a side bend part 12 that matches the size of the side frame. The side bend part 12 uses a glass bending machine and a flat plate. The part 11 is integrally formed by hot bending. The glass back cover adopts the 2320 series of Corning glass. The PET film 2 has an inner flat part 21 that matches the size of the back plate and an inner bend 22 that matches the size of the side frame. The bent part 22 and the inner flat part 21 are integrally punched and formed by a punching process. The glass back cover 1 is formed by a flat part 11 and a side bent part 12 to form a cavity. The PET film 2 is in the cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com