Dry type high-voltage capacitor core and making method thereof

A technology of high-voltage capacitors and capacitor cores, which is applied to the structural parts of electrical equipment, transformers/inductor coils/windings/connections, voltage dividers, etc., and can solve partial discharge and dielectric loss performance exceeding the standard, PTFE friction Problems such as low coefficient, interface air gap and moisture absorption can be achieved to improve the corona inception voltage and sliding voltage, without maintenance and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

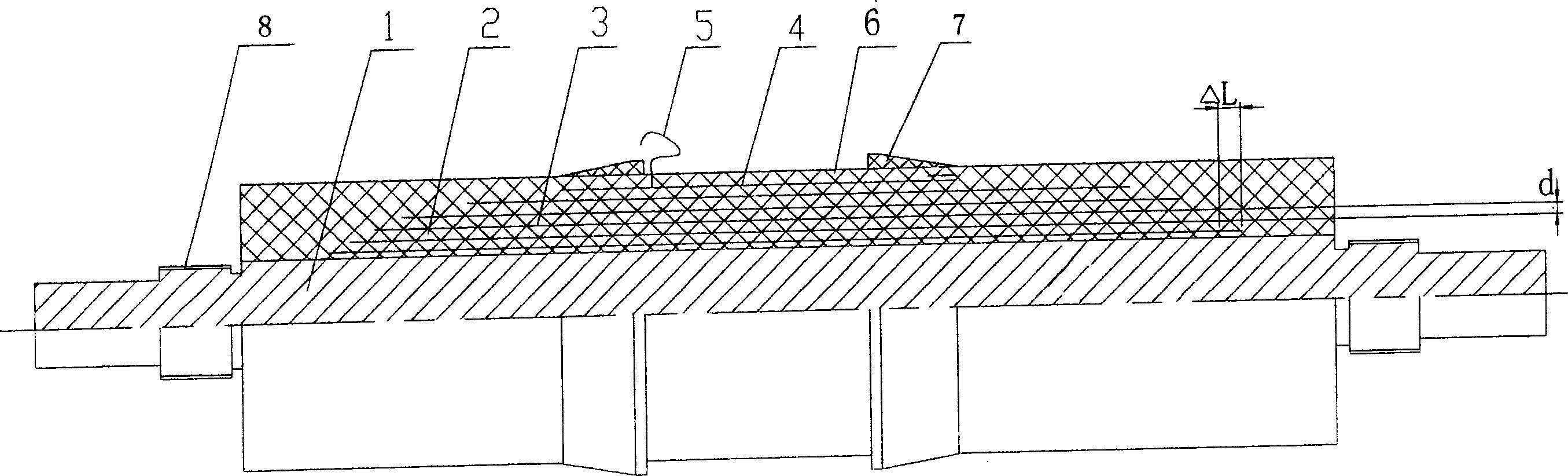

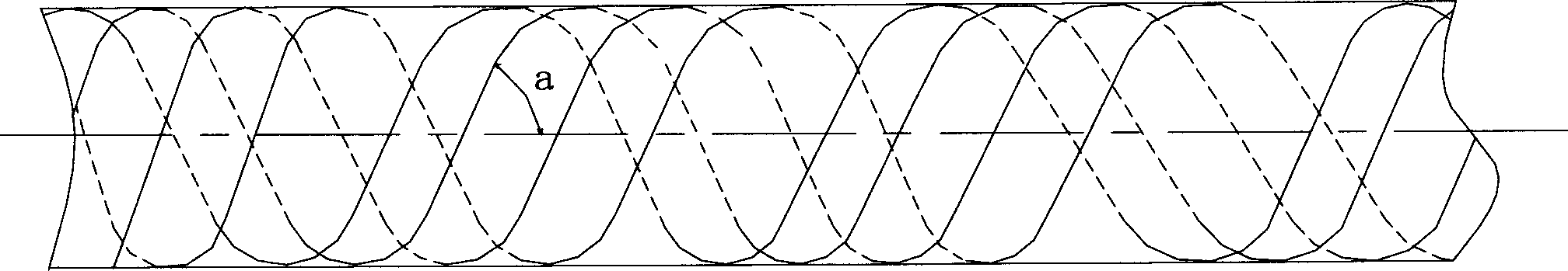

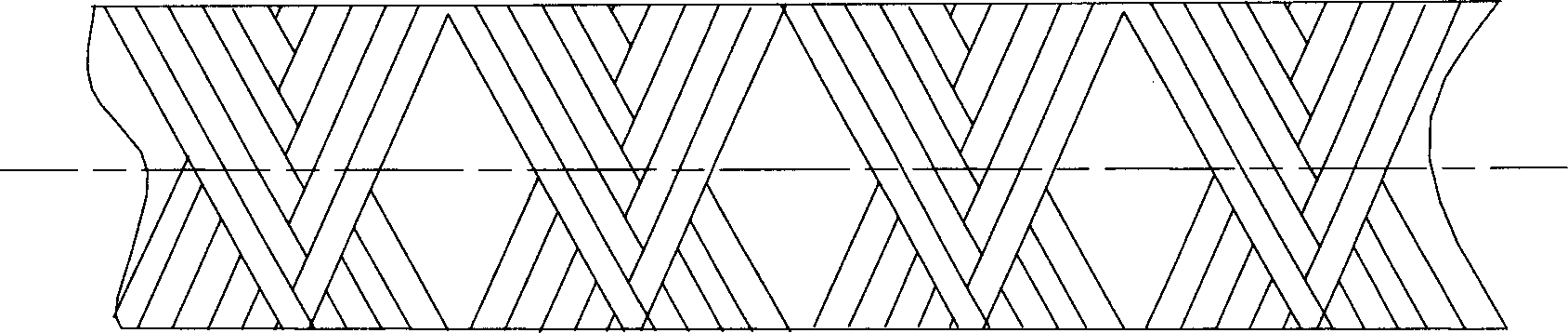

[0032] figure 1 It is a bushing insulator dry-type high-voltage capacitor core, which includes a current-carrying conductor 1, an insulating layer 2, a capacitive screen 3, a grounding terminal screen 4, a measurement lead-out line 5, and an insulating outer protective layer 6, wherein the inner insulation Layer 2 is made of alkali-free glass fiber roving impregnated with thermosetting epoxy resin curing material (the formula is: bisphenol A epoxy resin (E51), methyl tetrahydrophthalic anhydride (THPA), benzyl dimethylamine (BDMA ) and carboxylated nitrile rubber (CTBN) are evenly mixed into a bonding and curing glue in a ratio of 100:60:1.5:10), and wound in a certain way. The capacitive screen 3 is impregnated and bonded by polyacrylonitrile carbon fiber The above cured material is uniformly wound. In order to ensure the compactness, bending strength and interlayer flatness of the inner insulation, the fiber tows of the insulating layer between the capacitive screens are im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com