Test method for unshaded corona onset voltage of medium-voltage crosslinked polyethylene cable

A technology of cross-linked polyethylene and corona inception voltage, which is applied in the direction of testing dielectric strength, etc., to improve the corona inception voltage and avoid huge losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0024] Experimental example 1. Unshielded corona inception voltage test of medium voltage XLPE cable with stress tube

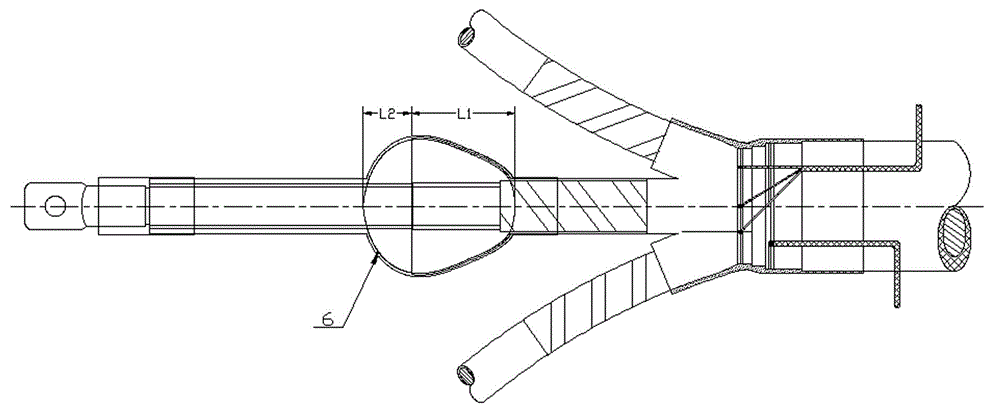

[0025] Choose YJV 22 -3×35mm 2 8.7 / 15kV XLPE cables are used as test items. Firstly, the cable head is made by using the current stress tube technology. The cable head of the stress tube cuts a 3×4mm square hole on the stress tube at the cutout of the semi-conductive layer, but as the sheath tube of the auxiliary insulating layer or the weather resistance The tube is not installed for the convenience of observing the corona during the test. The test site must be selected in a dark room without any light source.

[0026] The purpose of the test: to measure and determine the corona inception voltage value of the cable terminal made by using the stress tube process method.

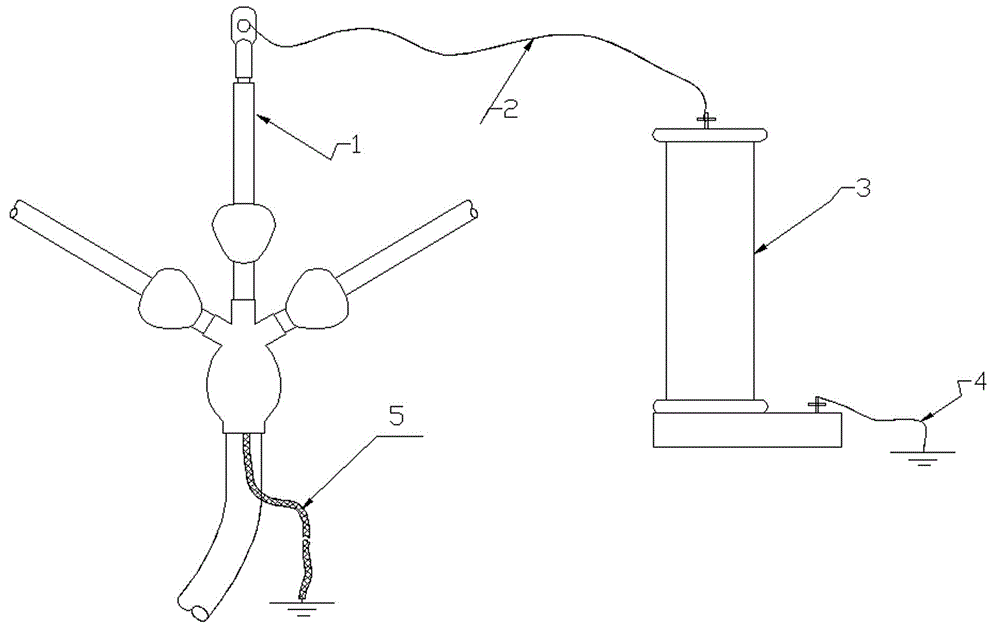

[0027] according to figure 1 As shown, ground the ground wire 5 of the cable shielding layer, connect the terminal of the cable lead wire 1 to the high voltage test connection wire 2, c...

experiment example 2

[0030] Experimental example 2. Unshielded corona inception voltage test of a medium voltage XLPE cable wrapped around a stress cone

[0031] This test method is the same as that of Experimental Example 1 above, and compared with Experimental Example 1. In order to avoid the quality deviation of different cables, especially the difference in the thickness and material of the cable insulation layer, the deviation of the experimental results is caused. The same 3.9-meter-long YJV with the same specification was selected for the test 22 -3×35mm 2 8.7 / 15kV XLPE cables are used as test items. At the other end of the same-phase cable that has been fitted with a stress tube in Experimental Example 1, a medium-voltage XLPE insulated stress-cone cable terminal was fabricated using the wrapping stress-cone process, and a comparison test of the cable head’s corona inception voltage was carried out. The patent application for the medium-voltage cross-linked polyethylene insulated stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com