Jet flow type electrochemical deposition device

A deposition equipment, electrochemical technology, applied in the direction of electrodes, electrolytic process, electrolytic components, etc., can solve the problems of excessive consumption of additives, contamination of ion membranes, etc., and achieve the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

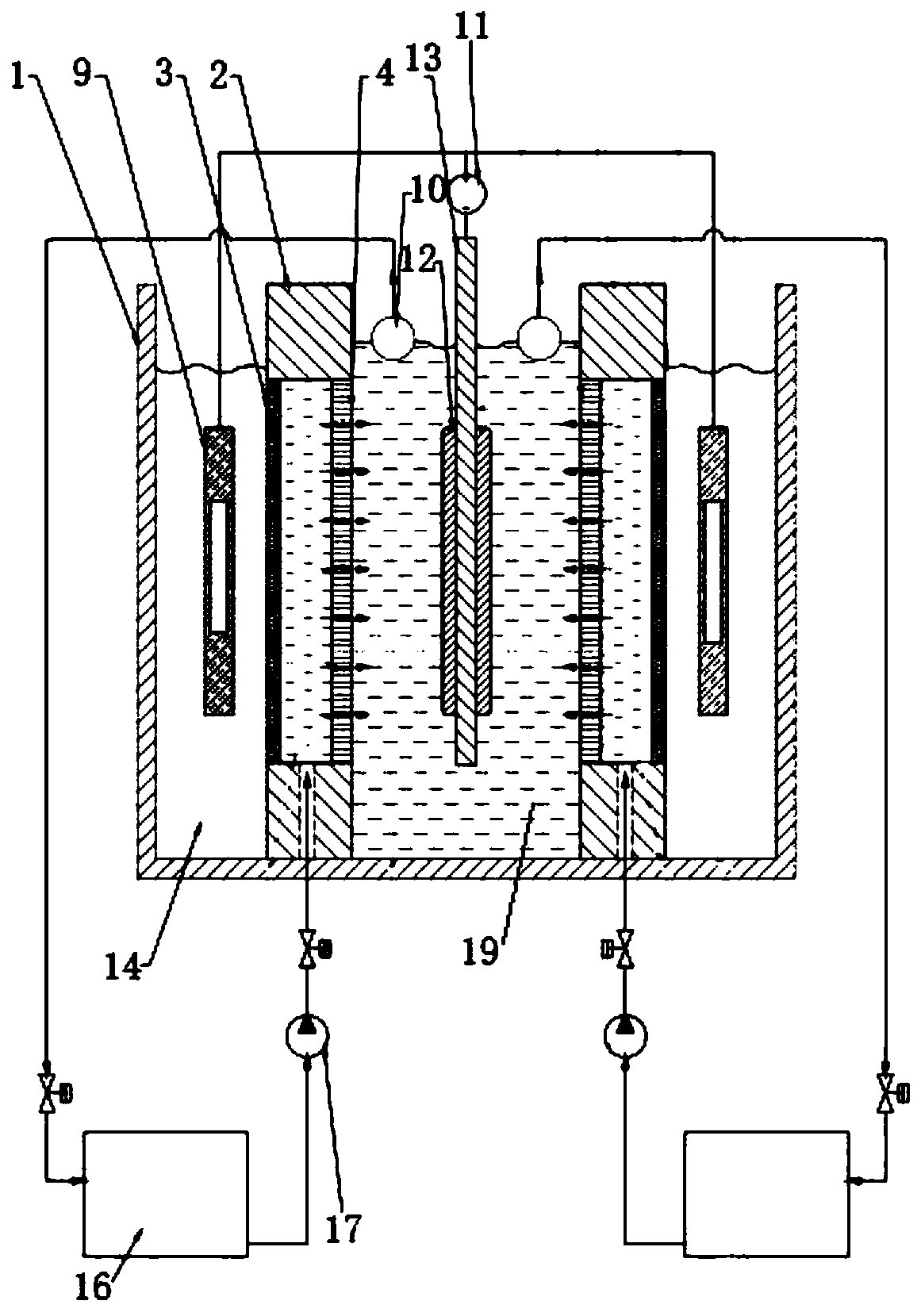

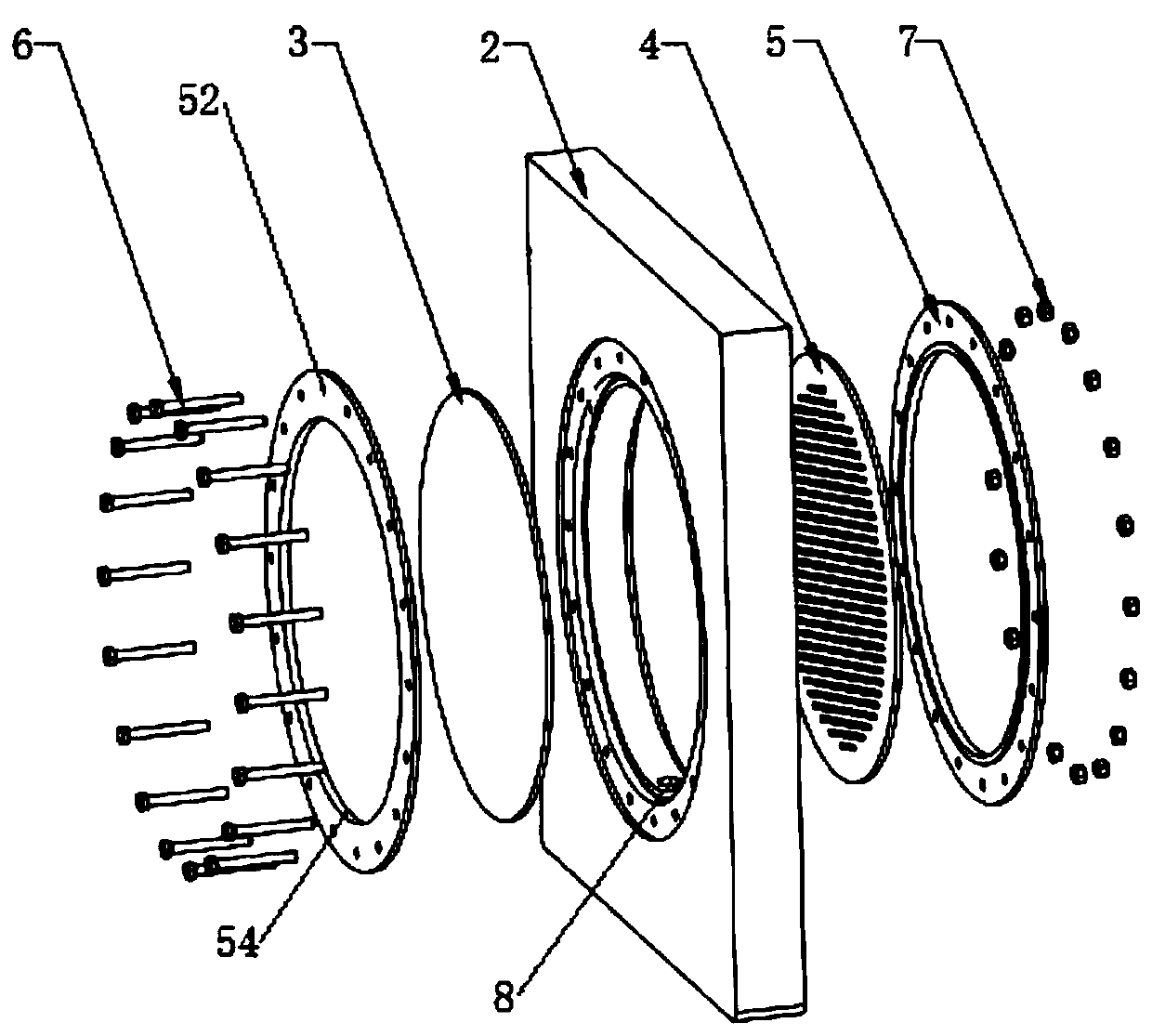

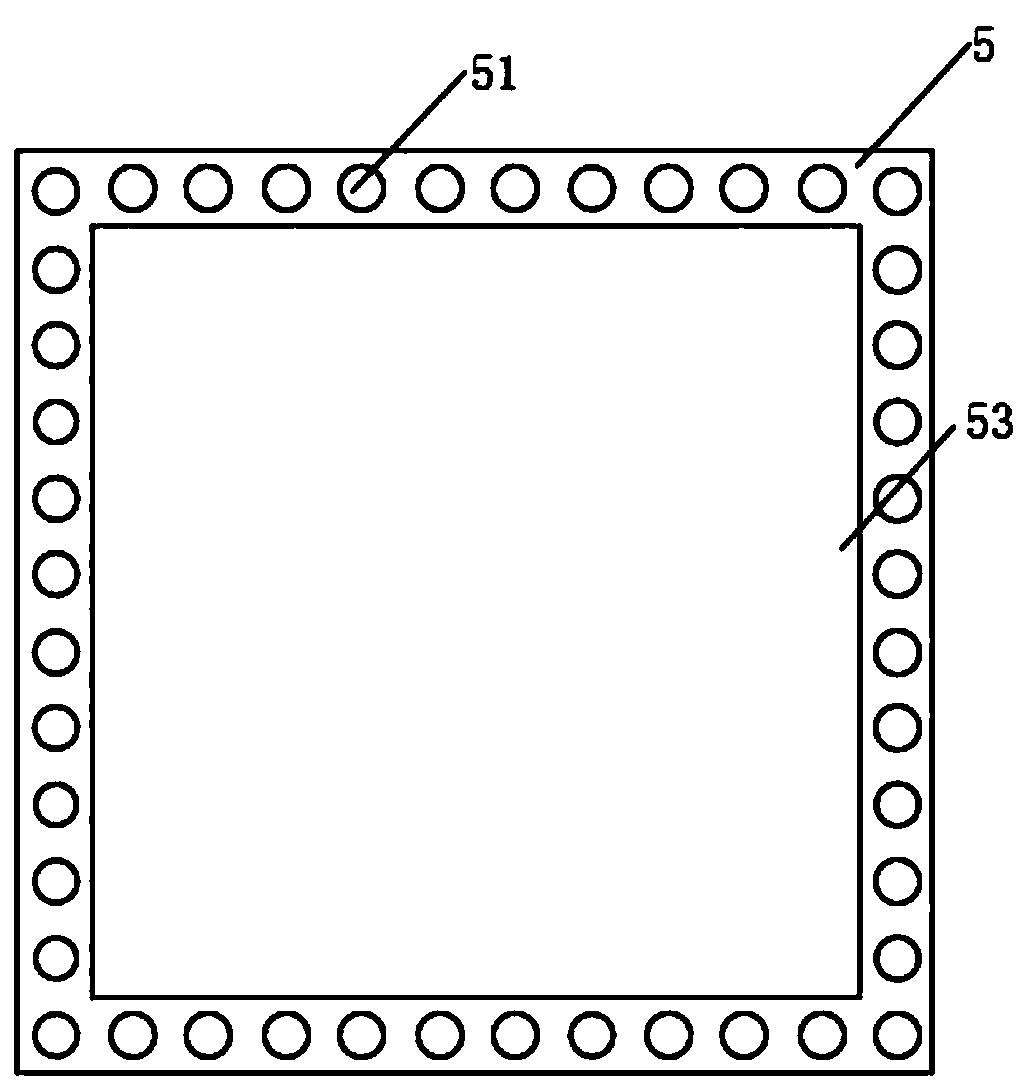

[0030] refer to figure 1 , 3 , 4, a kind of jet-flow electrochemical deposition equipment, comprise electroplating tank 1, substrate holder 13 is installed in the electroplating tank 1 tank, substrate holder 13 is installed with substrate 12, substrate holder 13 both sides The jet flow mechanism 2 is symmetrically arranged, the jet flow mechanism 2 is a hollow shell, and the diaphragm 3 and the jet flow plate 4 are respectively installed on both sides of the jet flow mechanism 2, and both ends of the jet flow mechanism 2 are installed There are fastening pads 5, a diaphragm 3, and a jet plate 4 are arranged between the two fastening pads 5, and a catholyte inlet hole 8 is provided at the bottom of the jet flow mechanism 2, and the catholyte inlet hole 8 is connected to a circulation pump 17 through a water pipe The water outlet of the circulating pump 17 is connected to the storage tank 16;

[0031] One side of the spray plate 4 is provided with a cathode chamber 19, and the...

Embodiment 2

[0034] refer to figure 1 , 2 , the difference between the jet flow electrochemical deposition equipment of this embodiment and embodiment 1 is that: the diaphragm 3, the jet flow plate 4, and the fastening pad 5 are all in a circular shape, and the fastening pad 5 is provided with a number of second passages in an upper arc. A fastening nut 6 runs through the inner wall of the hole 52 and the second through hole 52 , and a circular groove 54 is opened on the fastening pad 5 .

[0035] Turn on the DC power supply 11, and at the same time, the circulation pump 17 discharges the catholyte in the storage tank 16 to the jet mechanism 2 through the catholyte inlet hole 8, and the jet plate 4 on the jet mechanism 2 sprays the catholyte into the cathode chamber 19 , and the substrate 12 on the substrate holder 13 in the cathode chamber 19 is electrolyzed, and the catholyte overflowed during the electrolysis is discharged into the storage tank 16 through the overflow hole 10 and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com