Nickel plating protection clamp and nickel plating protection method

A technology for protecting fixtures and fixtures, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of uneven plating on the surface of the workpiece, affecting the performance of the workpiece, affecting the wear resistance and corrosion resistance of the workpiece, and improving the quality of electroplating. Guarantee Electroplating effect, the effect of improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

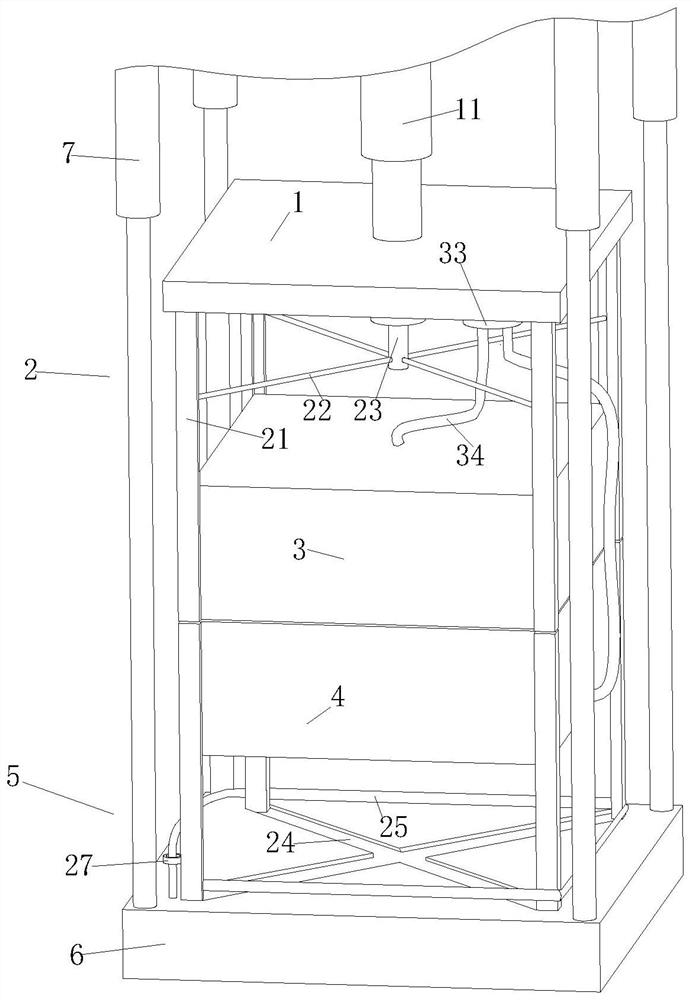

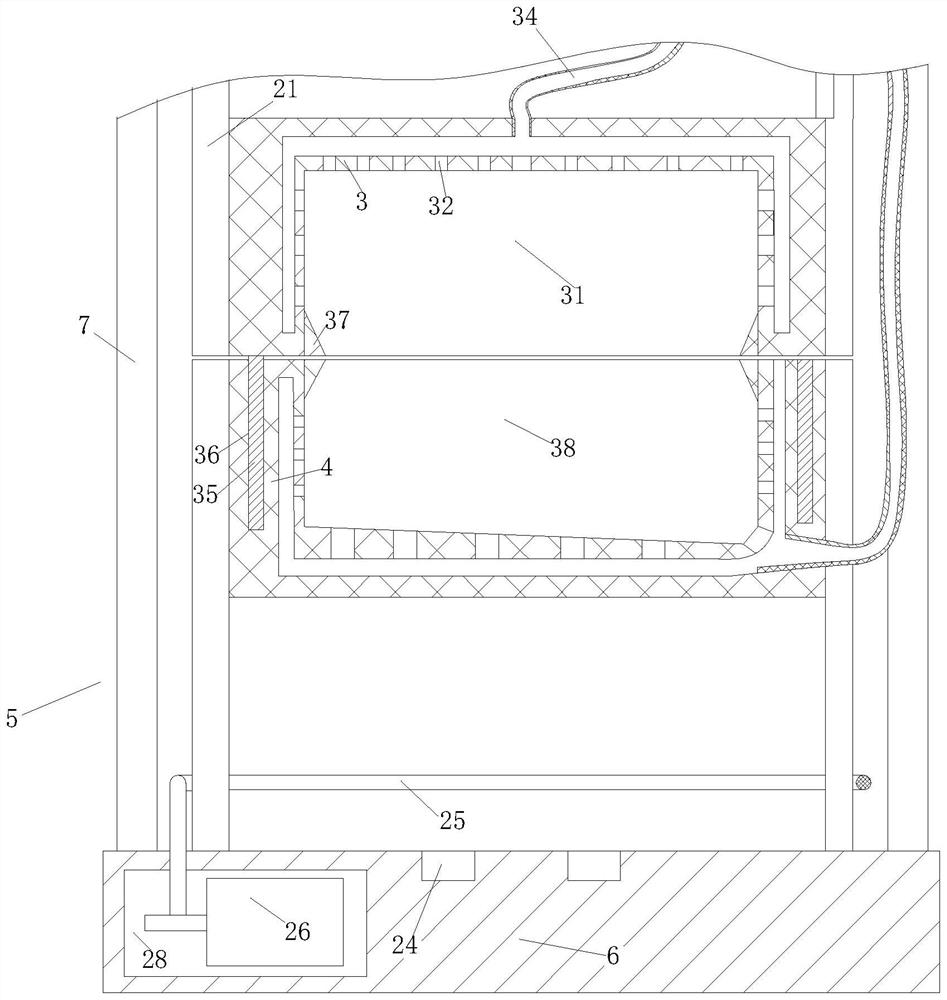

[0056] As an embodiment of the present invention, the upper expansion mechanism 2 includes an upper expansion rod 21, a No. 1 connecting rope 22 and a No. 1 motor 23; the end surface of the upper support plate 1 close to the upper clamp 3 is evenly provided with sliding grooves 24 The sliding groove 24 is arranged radially; the upper spreading rod 21 is evenly connected with the outer surface of the upper fixture 3, and the upper spreading rod 21 is slidably connected in the corresponding sliding groove 24, and the other end of the upper spreading rod 21 It is flush with the lower end surface of the upper fixture 3; the No. 1 motor 23 is fixedly connected with the upper support plate 1 and the output shaft is facing downward; the upper expansion rod 21 is fixedly connected with a No. 1 connecting rope 22 and the other end of the connecting rope is connected with the No. 1 The output shaft of the motor 23 is fixedly connected;

[0057] The lower stretching mechanism 5 comprises...

Embodiment 1

[0083] A nickel-plated protection fixture comprising:

[0084] The upper support plate 1, the upper end surface of the upper support plate 1 is fixedly connected with the No. 1 elevating rod 11;

[0085] The upper expansion mechanism 2 is connected to the lower end surface of the upper support plate 1;

[0086] The upper fixture 3, the upper fixture 3 is located below the upper stretching mechanism 2 and connected with the upper stretching mechanism 2, the lower end surface of the upper fixture 3 is provided with an upper wrapping groove 31; the upper wrapping groove 31 fits the upper half of the electroplating workpiece, and the upper wrapping groove 31 is used to clamp the upper part of the electroplating workpiece;

[0087] The lower fixture 4, the lower fixture 4 is located below the upper fixture 3, and the upper end of the lower fixture 4 is provided with a lower wrapping groove 38; the lower wrapping groove 38 fits the lower half of the electroplating workpiece, and th...

Embodiment 2

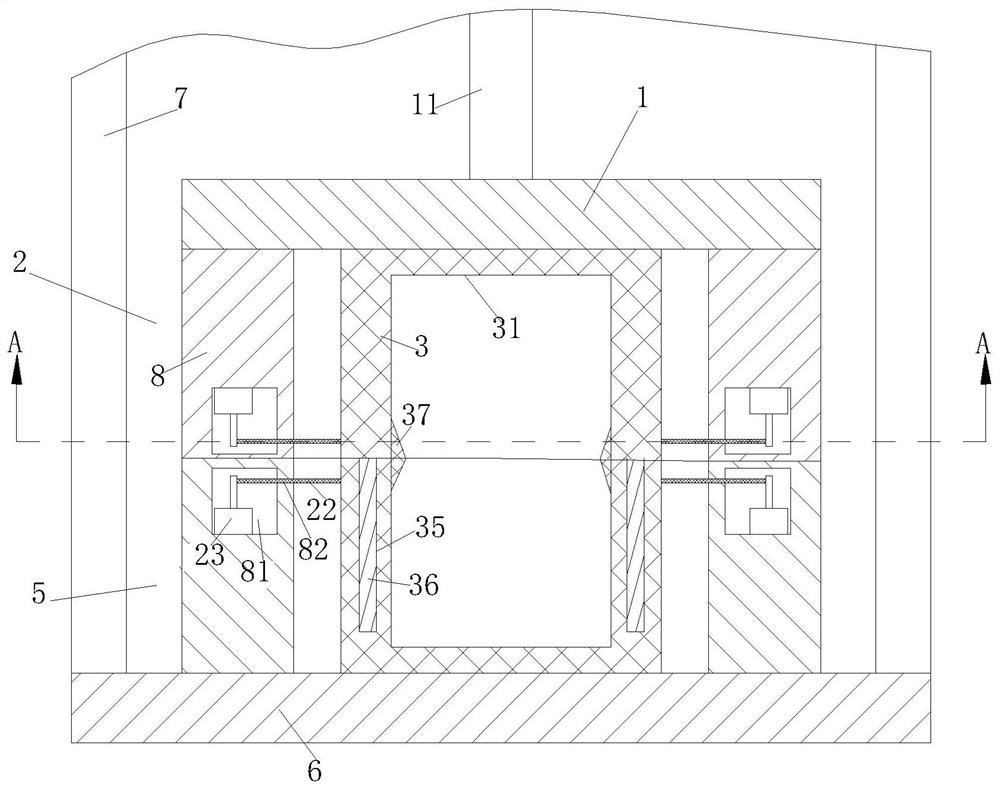

[0107] Compared with embodiment 1, the difference is:

[0108] In this embodiment, the upper stretching mechanism 2 includes an upper stretching block 8; the upper stretching block 8 surrounds the upper clamp 3, and the upper stretching block 8 is fixedly connected with the upper support plate 1; the upper clamp 3 and the upper stretching There is a gap between the blocks 8; the upper stretching block 8 is provided with an annular groove 81 and the No. 1 motor 23 is installed in the upper stretching block 8; the inner side wall of the annular groove 81 is evenly provided with a sealing groove 82; the sealing groove 82 runs through Stretching block; the end of the upper fixture 3 close to the lower fixture 4 is evenly connected with a No. 1 connecting rope 22; the number of the No. 1 connecting rope 22 is the same as that of the sealing groove 82 and after the No. 1 connecting rope 22 passes through the corresponding sealing groove 82 Winding on the output shaft of No. 1 motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com