Aluminum alloy casting electroplating production equipment and production process thereof

A technology for aluminum alloy castings and production equipment, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of affecting the electroplating effect and slow sanding speed, so as to ensure the electroplating effect and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065] Embodiment two: a kind of electroplating production process of aluminum alloy casting, specifically comprises the following steps:

[0066] 1) Loading, hang the aluminum alloy casting on the manipulator;

[0067] 2) Cleaning, at least 5 times, each time at least 2 minutes;

[0068] 3) Chemical degreasing, chemical degreasing in the solution, sodium hydroxide 30-50G / L, industrial detergent 0.5-1ML / L, water 70-125G, the temperature during the cleaning process is 50-60°C;

[0069] 4) Cleaning, same as process 2);

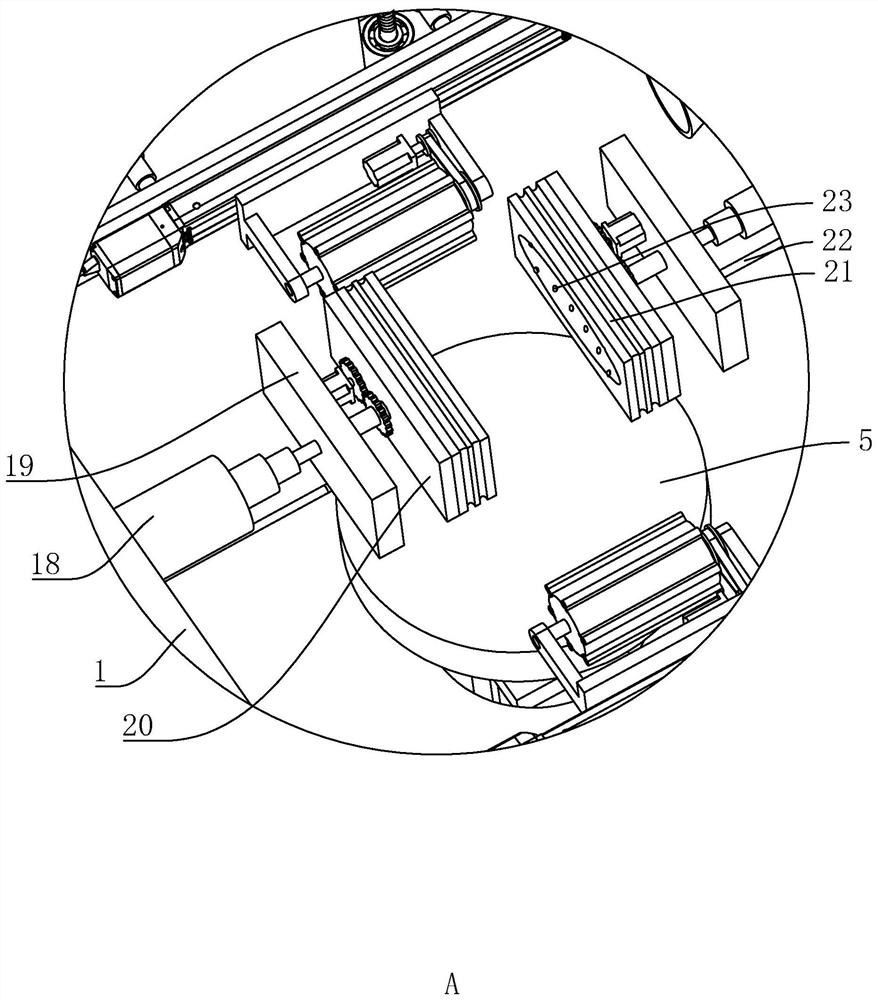

[0070] 5) Grinding the aluminum alloy castings, grinding the aluminum alloy castings in a vacuum state, grinding the aluminum alloy castings in a vacuum state can fully remove the oxide film on the surface of the aluminum alloy castings, and make the electroplating effect better;

[0071]6) Chemical electrolytic degreasing, electrolytic degreasing is carried out in the solution, the electrolytic degreasing time is 5-8min, and the mass ratio of the components o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com