Automatic charge bar charging equipment capable of avoiding material adhesion

An automatic, rod-based technology, applied in the direction of ejection equipment, metal processing equipment, feeding devices, etc., can solve problems affecting the quality of the material section, protection treatment of the material section, oxidation of the cutting surface, etc., to improve the quality of the blanking material, improve the The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention more clear and understandable, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

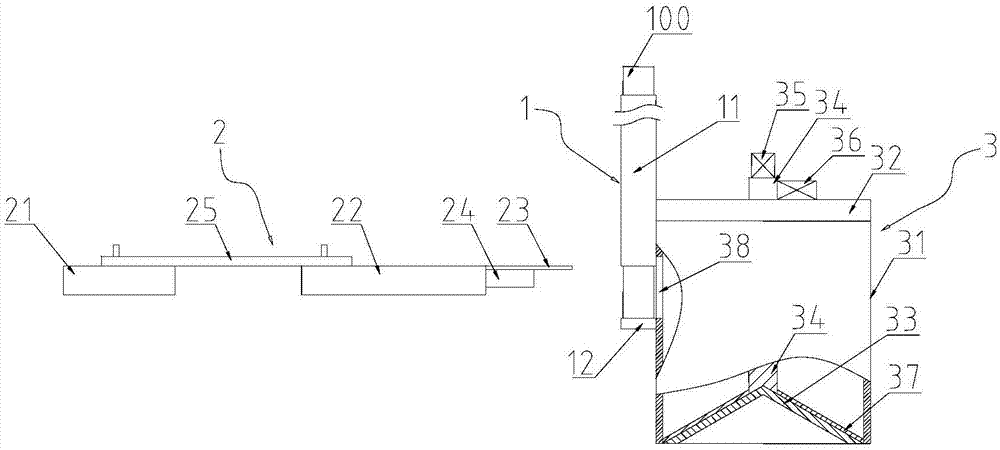

[0023] refer to figure 1 , figure 1 A schematic structural view of an automatic rod blanking device according to an embodiment of the present invention is schematically shown.

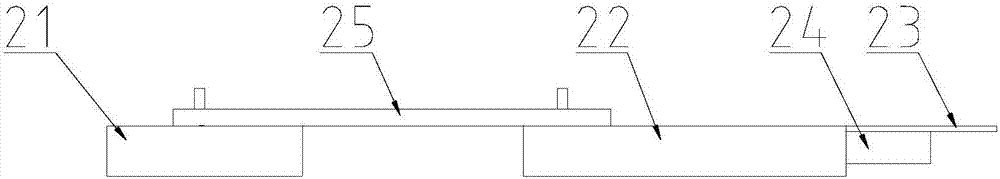

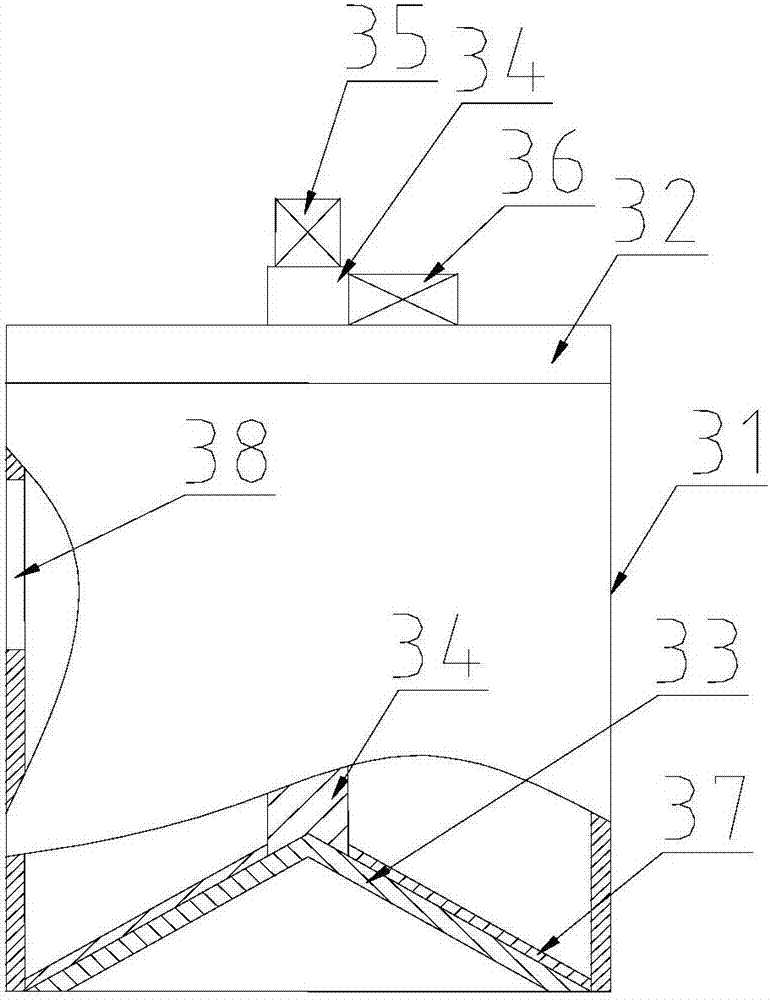

[0024] The automatic rod blanking equipment of this embodiment includes: a feeding mechanism 1, a blanking mechanism 2 and a discharging mechanism 3, through the cooperation of the feeding mechanism 1, the blanking mechanism 2 and the discharging mechanism 3, automatic feeding, Unloading and discharging greatly improves the working efficiency of the unloading equipment.

[0025] The feeding mechanism 1 is used to convey the material rod 100, and the feeding mechanism 1 includes: a material guide tube 11 for accommodating the material rod 100 and a material limiting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com