Continuous electroplating test device for simulating different linear speeds of strip steel

A test device and line speed technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of small test pieces, incapable of scanning electron microscope morphology analysis, low efficiency, etc., to achieve simple operation, ensure accuracy, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

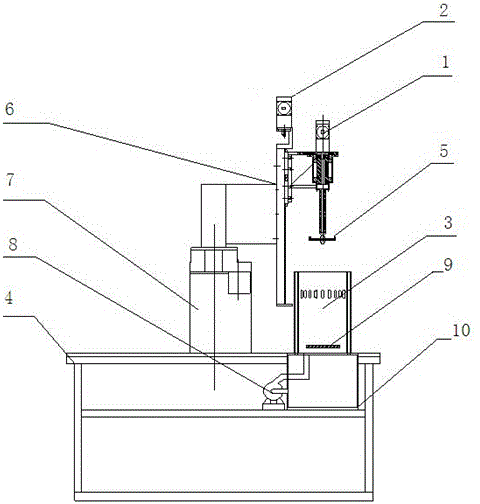

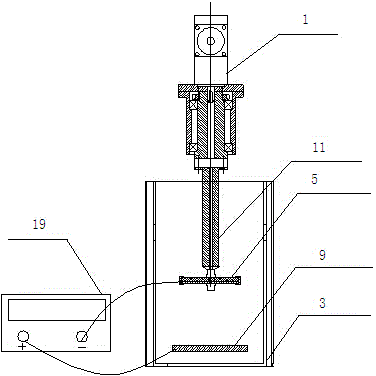

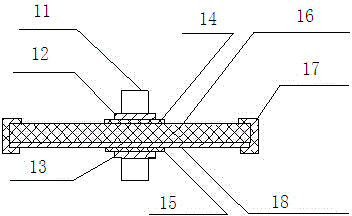

[0021] Example 1 : see figure 1 , a continuous electroplating test device simulating different linear speeds of strip steel, said test device comprises a support 4, said support 4 is provided with a workbench, said workbench is fixed with a working tank 3, and said test device also includes The working electrode system 5, the transmission shaft 11, the auxiliary electrode 9, and the sample working electrode 18, the transmission shaft 11 is connected to the working electrode system 5, and the auxiliary electrode 9 and the working electrode system 5 are both connected to the rectifier, forming a closed circuit, the sample working electrode 18 is installed on the working electrode system 5, and the functions of the cathode and anode are interchanged by changing the positive and negative poles of the rectifier, thereby realizing the simulation of the electroplating and cleaning process, and simulating the high-speed production of strip steel by adjusting the rotation of the motor...

Embodiment 2

[0022] Example 2 : see figure 1 , as an improvement of the present invention, the motor includes a rotating motor 1 and a vertical lifting motor 2, the vertical lifting motor 2 realizes vertical movement, and the rotating motor 1 drives the working motor through the transmission shaft 11 to realize high-speed rotation of the working electrode system. All the other structures and advantages are the same as in Embodiment 1.

Embodiment 3

[0023] Example 3 : see figure 2 , as an improvement of the present invention, the diameter of the auxiliary electrode 9 is larger than the diameter of the working electrode system 5 . Avoid uneven distribution of power lines during electroplating. All the other structures and advantages are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com