Dehydrating agent, preparation method of dehydrating agent, hydrocarbon water cutting agent and preparation method of hydrocarbon water cutting agent

A technology of hydrocarbon water cutting agent and dehydrating agent, which is applied in the field of chemical cleaning, can solve the problems of poor dehydration effect and long processing time, and achieve the effect of ensuring electroplating effect, high efficiency and good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

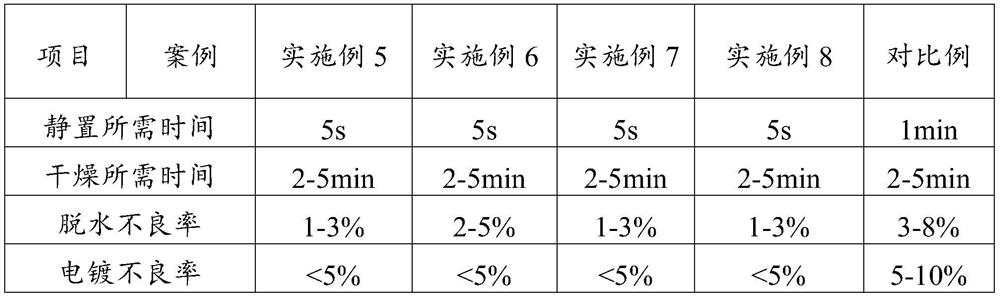

Examples

preparation example Construction

[0029] The present invention also proposes a method for preparing the dehydrating agent as described above, comprising the following steps:

[0030] Mix alcohol ether solvents, phase transfer catalysts, long-chain primary amines and short-chain carboxylic acids evenly, and react at 23-27°C for 20-30 minutes to obtain a dehydrating agent.

[0031] The present invention does not limit the feeding order of alcohol ether solvents, phase transfer catalysts, long-chain primary amines, and short-chain carboxylic acids. Preferably, alcohol ether solvents are added first, and then phase transfer catalysts are added. After stirring and dissolving, sequentially add The order of addition of long-chain primary amine and short-chain carboxylic acid makes the color, state, effect and stability of the hydrocarbon water cutting agent finally prepared by the dehydrating agent better.

[0032] The present invention improves the composition and proportion of the dehydrating agent, so that the pre...

Embodiment 1

[0041] (1) Weigh raw materials: 33.25g dimethyl propylene glycol methyl ether (66.5%), 3.5g methyl trioctyl ammonium chloride (7%), 7.25g dodecylamine (14.5%), 6g octanoic acid (12% ).

[0042] (2) Add dimethyl propylene glycol methyl ether into the reaction kettle, then add methyl trioctyl ammonium chloride, stir and dissolve, then add dodecylamine and octanoic acid in turn, and stir for 30 minutes at 25°C to form a transparent reaction The product N-(dodecyl) octyl amide is a dehydrating agent.

Embodiment 2

[0044] (1) Weigh raw materials: 30g ethylene glycol tert-butyl ether (60%), 2.5g methyl trioctyl ammonium chloride (5%), 5g tetradecylamine (10%), 7.5g hexanoic acid (15%) %).

[0045](2) Add ethylene glycol tert-butyl ether into the reaction kettle, then add methyl trioctyl ammonium chloride, stir to dissolve, then add tetradecylamine and hexanoic acid, and stir for 25 minutes at 27°C to form a transparent The reaction product, N-(tetradecyl)hexylamide, is the dehydrating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com