Plating tank plated evenly

An electroplating tank and uniform technology, applied in the direction of plating tank, electrolytic process, electrolytic components, etc., can solve the problems of difficult positioning of anode plate or cathode plate, difficulty of filtering impurities in bath liquid, difficulty in controlling the temperature of electroplating bath liquid, etc., and achieve easy Replacement, easy adjustment, easy positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described.

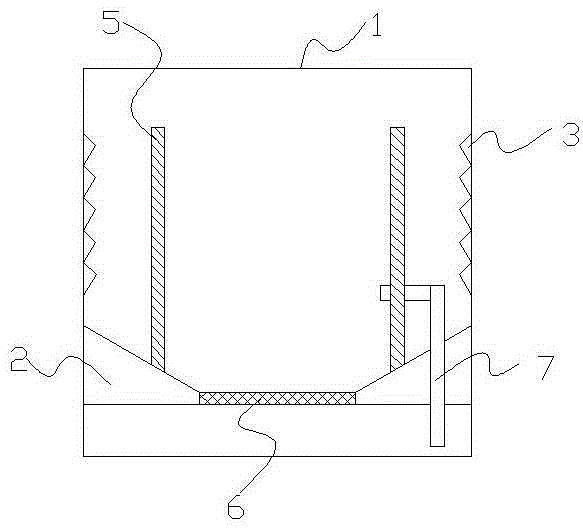

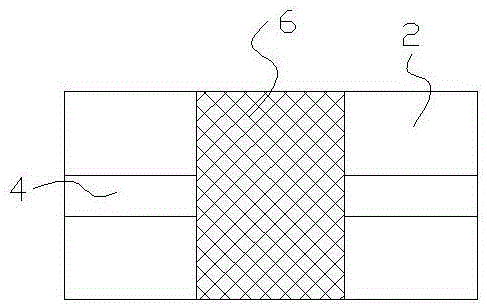

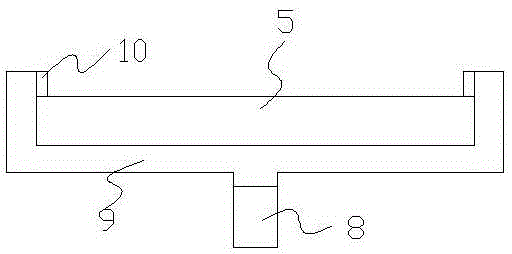

[0011] As shown in the figure, the electroplating tank with uniform electroplating includes a tank body 1, a partition plate 2 is fixedly connected to the opposite inner sides of the two side walls of the tank body, and a heating device 3 is also provided on the two side walls, The partition has a slope with a certain angle between the extension line and the bottom wall of the tank body, a slide 4 is provided on the partition, and an anode plate 5 is connected to the slide, and the two partitions are fixedly connected. There is a filter device 6, and a return pipe 7 is arranged in the tank body, and the return pipe passes through one of the partitions so that one end of the return pipe is close to the bottom wall of the tank body and is located below the partition, and the other end is located above the partition and located on the partition. One end of the upper return pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com