Electroplating device

An electroplating device and electroplating tank technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of inconsistent effect, uneven effect, unable to maintain the consistency of electroplating effect, etc., and achieve the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

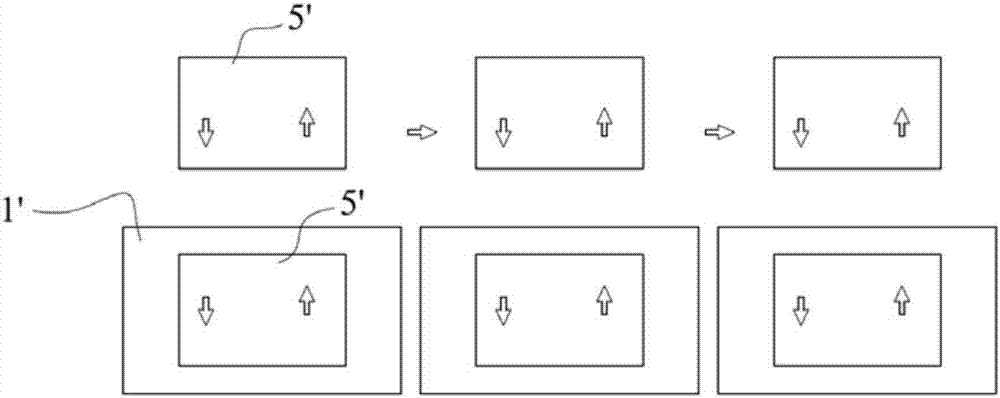

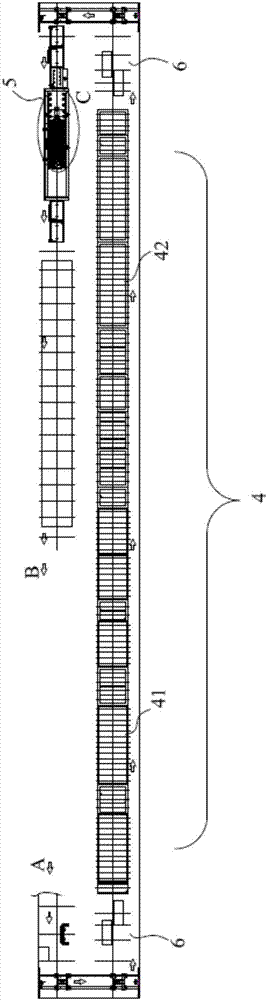

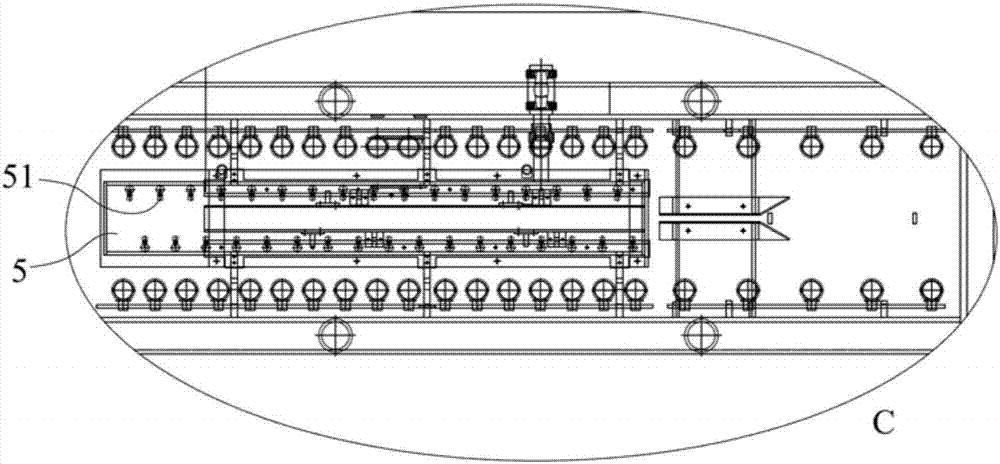

[0026] Such as Figure 2-Figure 8 As shown, the present invention provides an electroplating device, which includes a track, a crane 2 , a hanger 3 , a pretreatment tank 4 and an electroplating tank 5 . The track is fixed with the fixed frame, and the fixed frame is supported on the ground. The track is laid at a certain height from the ground and along the conveying direction of the workpiece 8 .

[0027] The crane 2 includes a moving part 21 and a lifting part 22 , the moving part 21 moves along the track, and the lifting part 22 is connected with the moving part 21 .

[0028] The hanger 3 is used to carry or clamp the workpiece 8. In some areas of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com