Electroplating apparatus

An electroplating equipment and plating technology, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of wasting plated metal, increase production costs, and increase the cost of plating containers, and achieve uniform plating and reduce material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. While specific structural and functional details are disclosed, such disclosure is for the sole purpose of enabling those of ordinary skill in the art to make and practice the invention. No details described below or depicted in the accompanying drawings should in any way be construed as limitations on the scope of the invention which may be embodied in many alternative forms than those described herein. For the sake of clarity and conciseness, matters related to the present invention that are not necessary for a full understanding and practice of the invention will not be described herein.

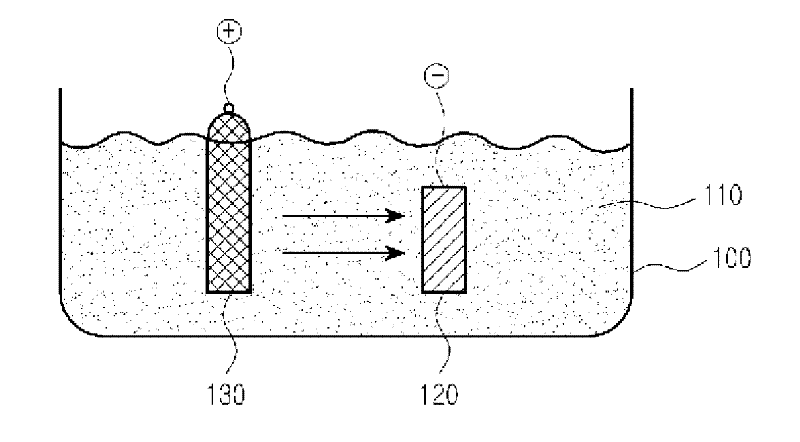

[0024] The present invention is directed to a plating apparatus capable of uniformly and quickly plating regions of objects to be plated having various shapes using at least one of wet plating and spray plating.

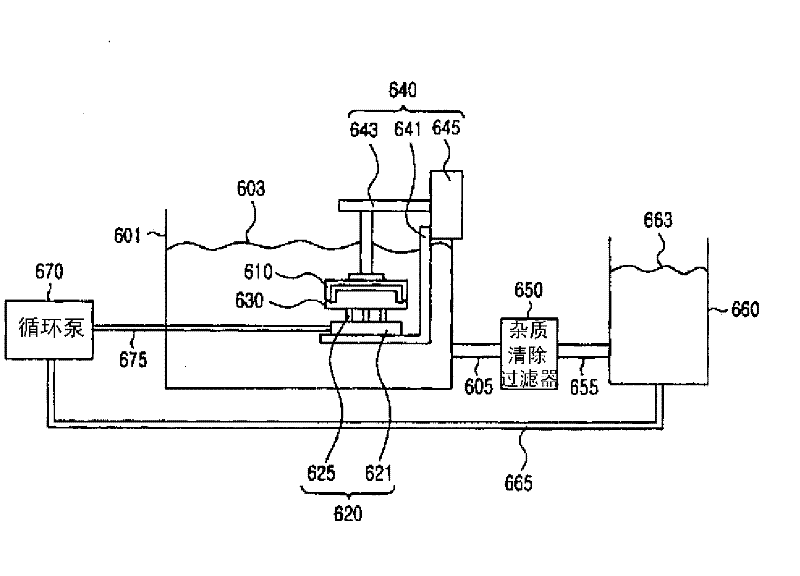

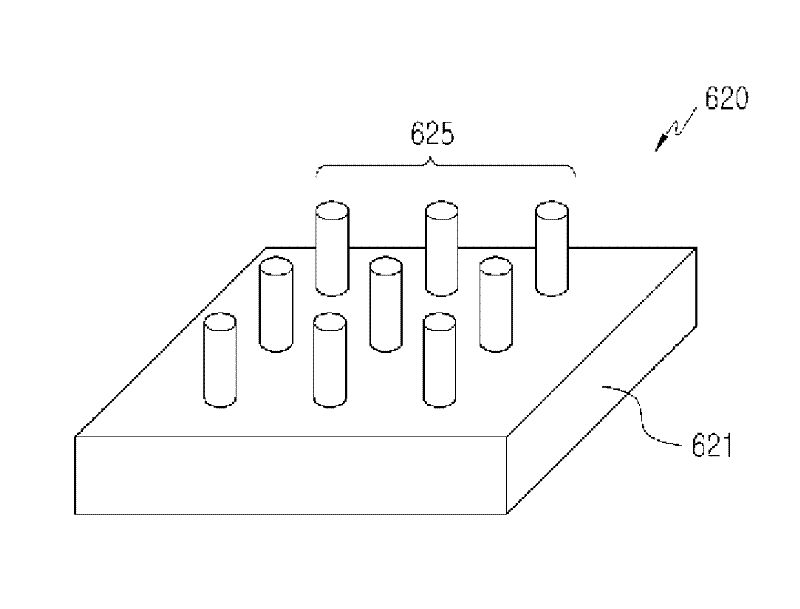

[0025] figure 2 An electroplating apparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com