Method for local electroplating sheltering and hanging aluminium alloy cavity of communication filter

A local electroplating, aluminum alloy technology, applied in the electrolytic process, electrolytic components and other directions, can solve the problems of poor electroplating solution, affecting electroplating effect, high temperature tape viscosity reduction, etc., to reduce production costs, improve product quality, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

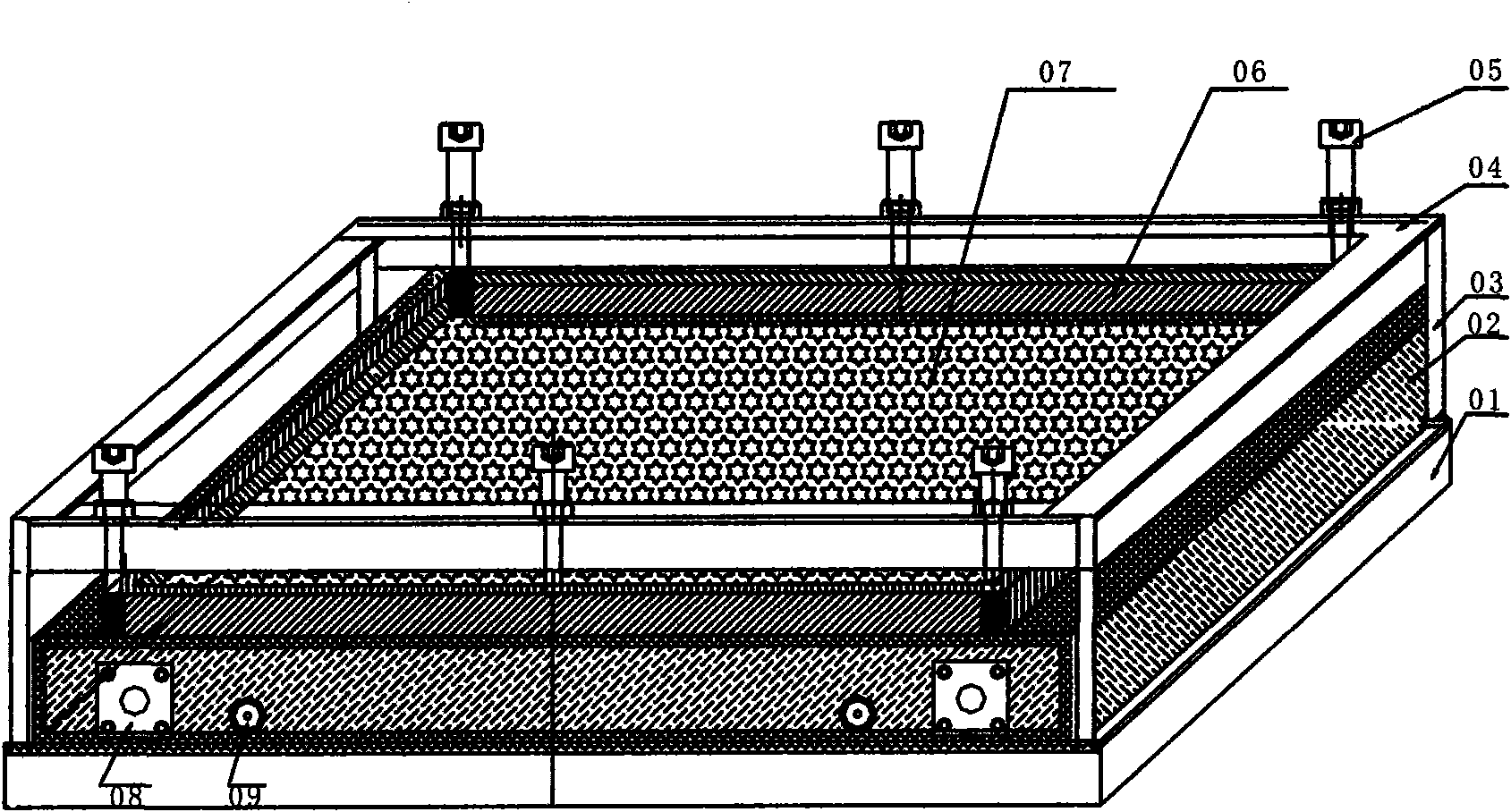

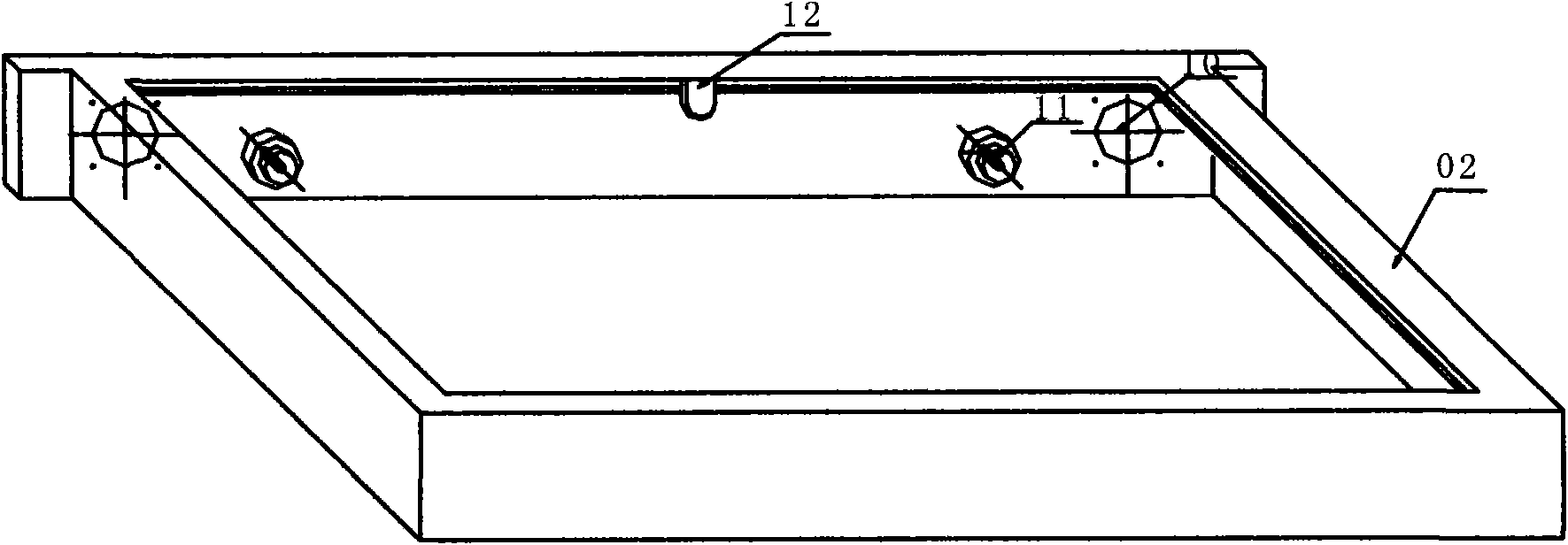

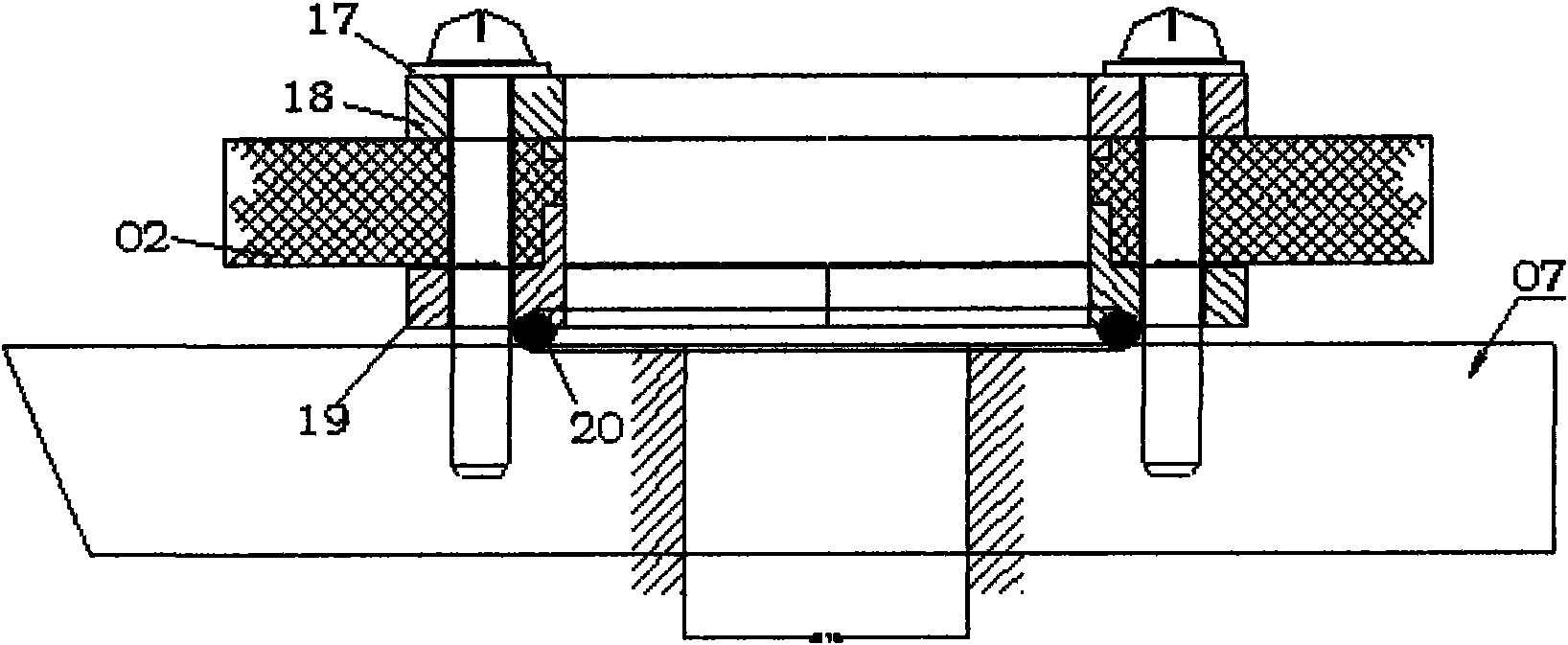

[0020] Such as figure 1 As shown, first, according to the shape of the aluminum alloy cavity 07 of the communication filter to be plated, a silicone waterproof cover 02 matching it is manufactured, and then the silicone waterproof cover 02 is put on the surface of the aluminum alloy cavity 07. see figure 2 , wherein, where there are deep holes on the surface of the aluminum alloy cavity, PK bolts and O-rings are used to seal the through holes of the aluminum alloy cavity. There are 11 deep holes in the aluminum alloy cavity, and a hollow cylindrical rubber plug 09 should be provided opposite to the silicone waterproof sleeve. The hollow cylindrical rubber plug 09 and the silicone waterproof sleeve are formed at the same time. There are 12 gaps formed in the upper part of the aluminum alloy cavity, and there is a step-shaped silicone pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com