Technology and equipment for coating film in deep hole

A technology and equipment technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of inability to achieve uniform coating on the inner surface, limited deep hole coating capacity, poor deposition uniformity, etc., to achieve convenient Industrial application of inner plating, the effect of improving the uniformity of the coating and improving the coating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

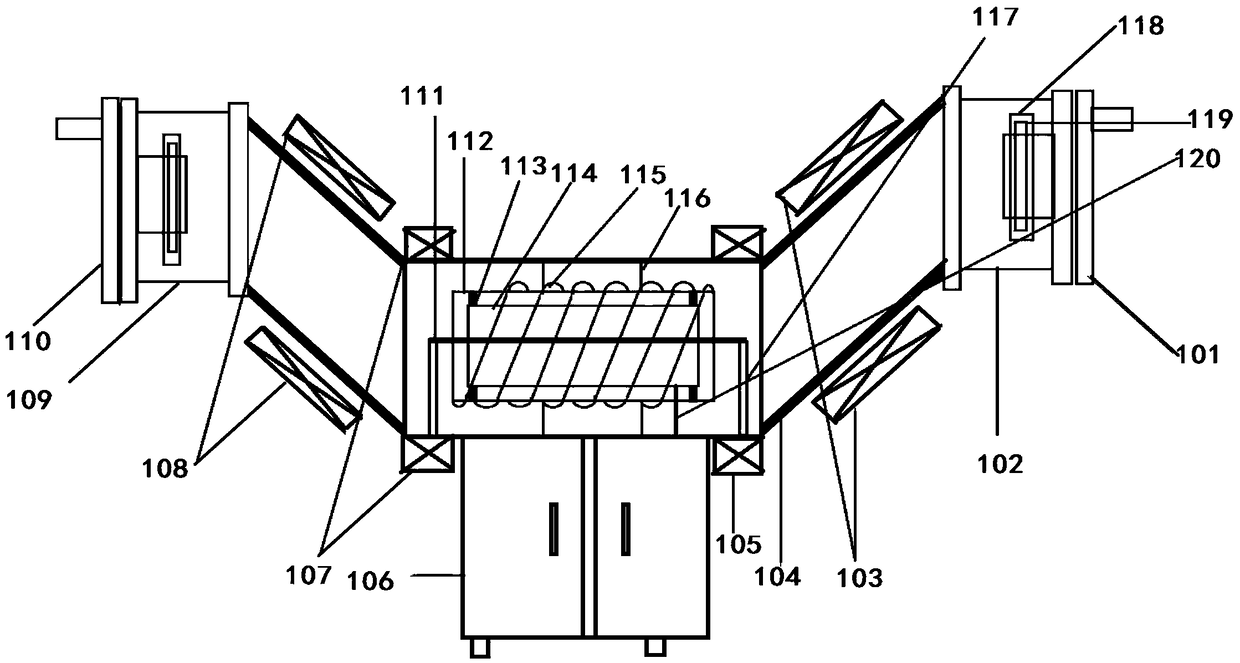

Embodiment 1

[0062] The inner diameter of the plated cylinder is 80mm, the outer diameter is 110mm, and the length is 1100mm. The inner diameter of the selected outer insulating ceramic cylinder is 120mm. The cleaning vacuum before coating is 0.5-2Pa, Ar:H 2 The discharge voltage is 10:1, the discharge voltage is 800V, and the cleaning time is 30-60min; the arcing current is 30A when the plating cylinder is coated, and the vacuum degree is 1×10 -3 Pa, the bias voltage is -800V-800V alternately, the frequency is 50Hz, the magnetic field and other parameters of each wire package are as follows:

[0063] 103: DC current 3A;

[0064] 105: DC current 2A, pulse current frequency 50Hz, current 50A;

[0065] 107: DC current 2A, pulse current frequency 50Hz, current 50A;

[0066] 108: DC current 3A;

[0067] 115: Strong pulse line package: -50A-50A, frequency 100Hz;

Embodiment 2

[0069] The inner diameter of the plated cylinder is 60mm, the outer diameter is 90mm, and the length is 1100mm. The inner diameter of the selected outer insulating ceramic cylinder is 110mm. The cleaning vacuum before coating is 0.5-2Pa, Ar:H 2 The discharge voltage is 10:1, the discharge voltage is 800V, and the cleaning time is 30-60min; the arcing current is 30A when the plated cylinder is coated, and the vacuum degree is 1×10 -3 Pa, the bias voltage is -800V-800V alternately, the frequency is 50Hz, the magnetic field and other parameters of each wire package are as follows:

[0070] 103: DC current 3A;

[0071] 105: DC current 2A, pulse current frequency 50Hz, current 50A;

[0072] 107: DC current 2A, pulse current frequency 50Hz, current 50A;

[0073] 108: DC current 3A;

[0074] 115: Strong pulse line package: -300A-300A, frequency 100Hz;

Embodiment 3

[0076] The inner diameter of the plated cylinder is 40mm, the outer diameter is 60mm, and the length is 1100mm. The inner diameter of the selected outer insulating ceramic cylinder is 80mm. The cleaning vacuum before coating is 0.5-2Pa, Ar:H 2 The discharge voltage is 10:1, the discharge voltage is 800V, and the cleaning time is 30-60min; the arcing current is 30A when the plated cylinder is coated, and the vacuum degree is 1×10 -3 Pa, the bias voltage is -800V-800V alternately, the frequency is 50Hz, the magnetic field and other parameters of each wire package are as follows:

[0077] 103: DC current 3A;

[0078] 105: DC current 2A, pulse current frequency 50Hz, current 50A;

[0079] 107: DC current 2A, pulse current frequency 50Hz, current 50A;

[0080] 108: DC current 3A;

[0081] 115: Strong pulse line package: -800A-800A, frequency 100Hz;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com