Method for chemical plating of metal on particle surface

A particle surface, chemical plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of uneven surface plating, too fast plating speed, unstable plating solution, etc. Avoid the effects of unstable plating solution, easy operation and uniform particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

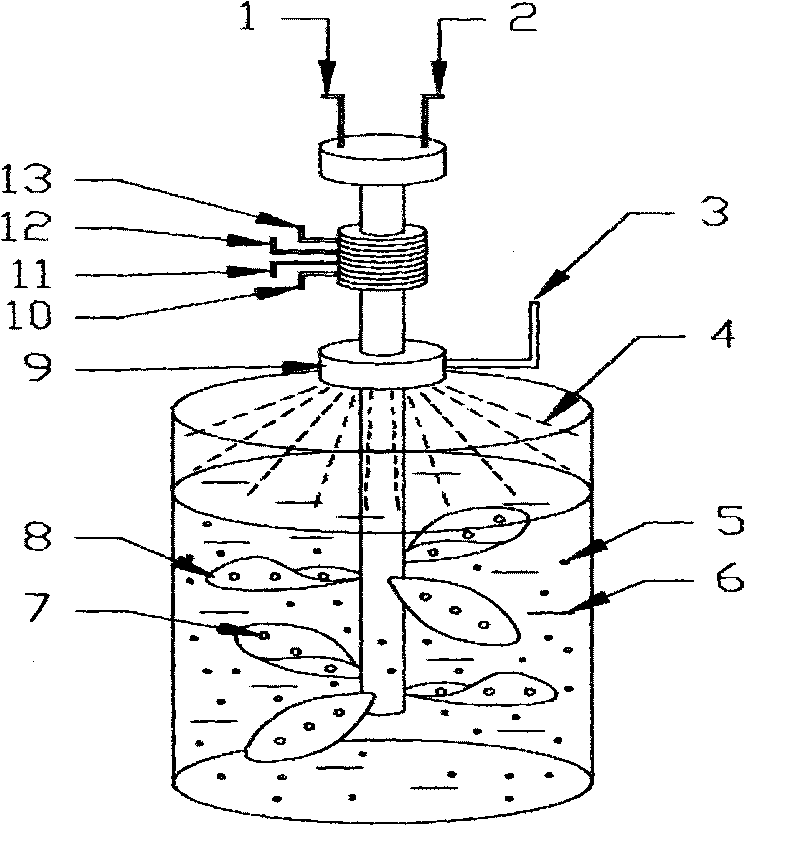

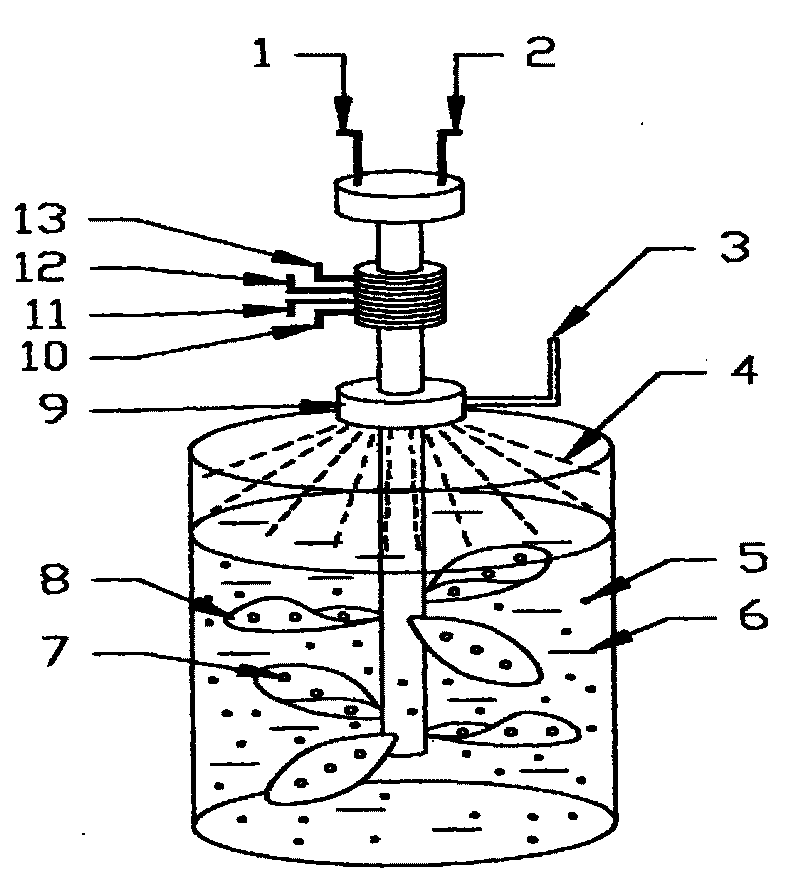

Method used

Image

Examples

Embodiment 1

[0026] Take Ag metal on the surface of WC powder particles with an average particle size of 0.01μm as an example

[0027] First, 5g WC powder particles (with a particle size of 0.01 μm) are placed in a 5% nitric acid solution, stirred and cleaned for 10 minutes, and then cleaned with deionized water for three times and then filtered by suction.

[0028] Pour the powder particles after suction filtration into 500ml of hydrazine hydrate solution, the concentration of which is 3ml / L, adjust the PH value to 8 with ammonia water, the stirring speed is 500 rpm, the ultrasonic vibration frequency is 100KHz, and the stirring ultrasonic vibration is 15 minutes .

[0029] Then 500ml of silver nitrate solution with a concentration of 10g / L was added in the form of spray, and the silver nitrate solution was added at a speed of 5ml / min. After the electroless plating was completed, the coated WC powder particles were obtained by suction filtration and rinsed with deionized water all over.

[0030]...

Embodiment 2

[0032] Take Ag metal coated on the surface of WC powder particles with an average particle size of 1μm as an example

[0033] Firstly, 15 g of WC powder particles (with a particle size of 1 μm) were placed in a 5% nitric acid solution, stirred and washed for 5 minutes, and then washed with deionized water for three times and then filtered with suction.

[0034] Pour the powder particles after suction filtration into 500ml hydrazine hydrate solution, the concentration of which is 6ml / L, adjust the PH value to 10 with ammonia water, stir and ultrasonically shake, and then add 500ml silver nitrate solution with a concentration of 30g / L in the form of spray , The silver nitrate addition speed is 30ml / L, the stirring speed is 200 revolutions / min, and the ultrasonic vibration frequency is 15KHz.

[0035] After the electroless plating is completed, the coated WC powder particles are obtained by suction filtration, and rinsed with deionized water three times.

[0036] After that, the coated W...

Embodiment 3

[0038] Take Ag metal coated on the surface of SiC powder particles with an average particle size of 2μm as an example

[0039] First, 8 g of SiC powder particles (with a particle size of 2 μm) were placed in a 10% nitric acid solution, stirred and cleaned for 10 minutes, and then cleaned with deionized water for three times and then filtered by suction. The powder particles after suction filtration are sensitized and activated, using 15% SnCl 2 Solution sensitization and 20% PdCl solution activation treatment, followed by washing with deionized water three times.

[0040] Then, the above-mentioned processed powder particles are poured into 500 ml of hydrazine hydrate solution, the concentration of which is 4.5 ml / L, the pH value is adjusted to 9 with ammonia water, and the mixture is stirred and ultrasonically shaken. Then 500ml of silver nitrate solution with a concentration of 15g / L was added in the form of spray, the silver nitrate addition speed was 45ml / min, the stirring speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com