Electroplating device for printed breadboard

A technology for printed circuit boards and electroplating devices, used in jewelry and other directions, can solve problems such as affecting product processing quality, inability to accurately control line width tolerance, and uneven copper plating thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

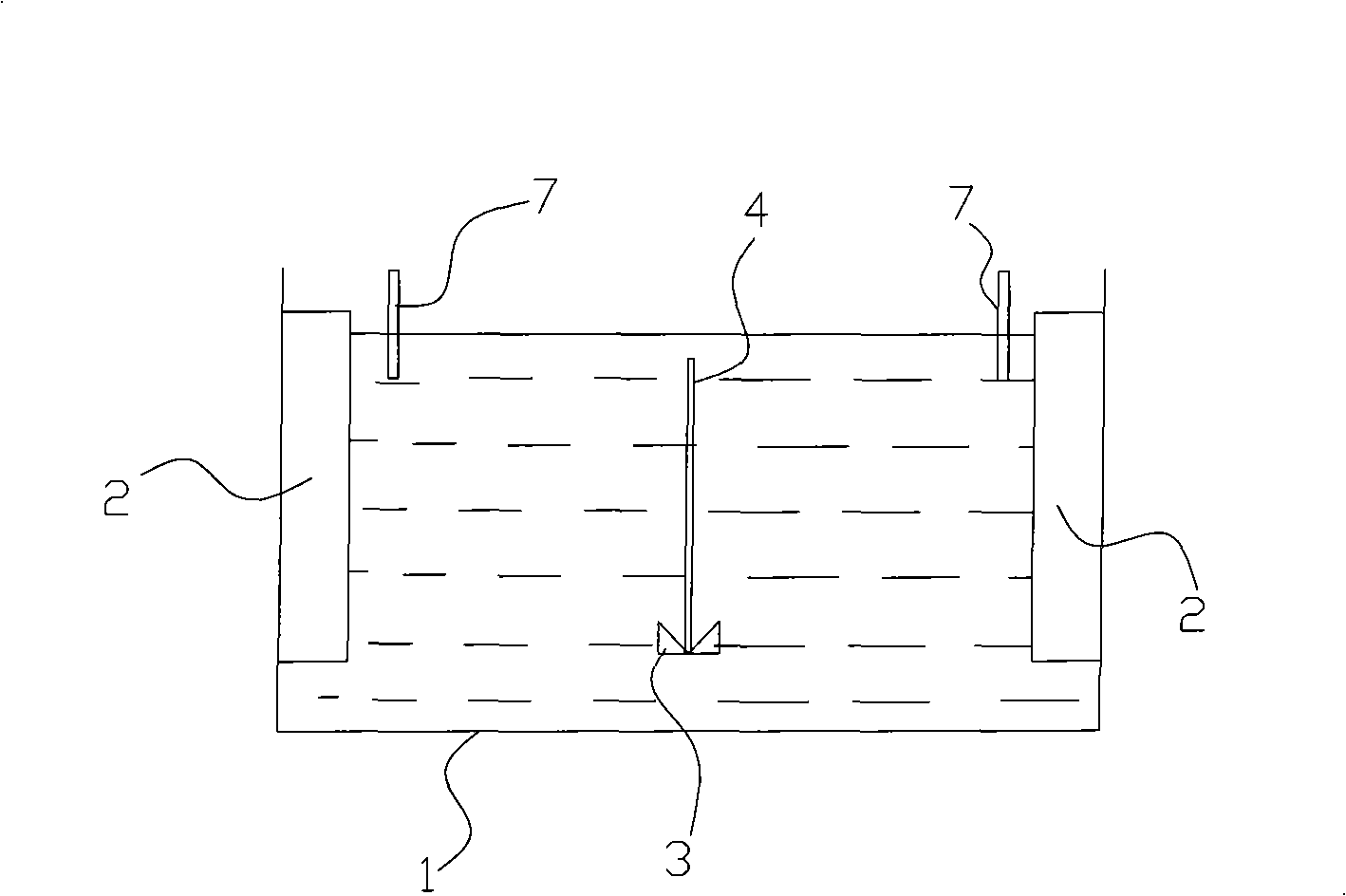

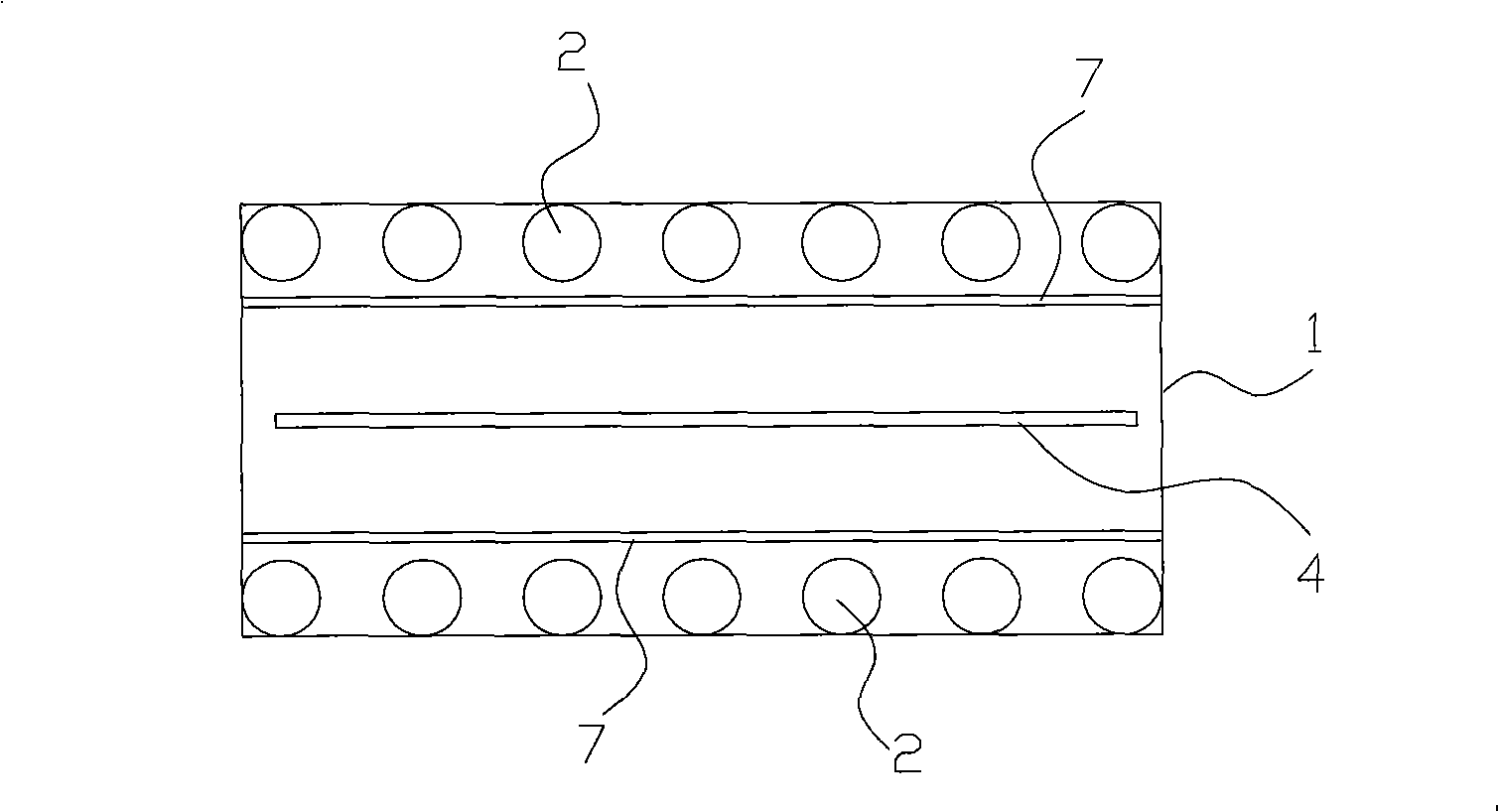

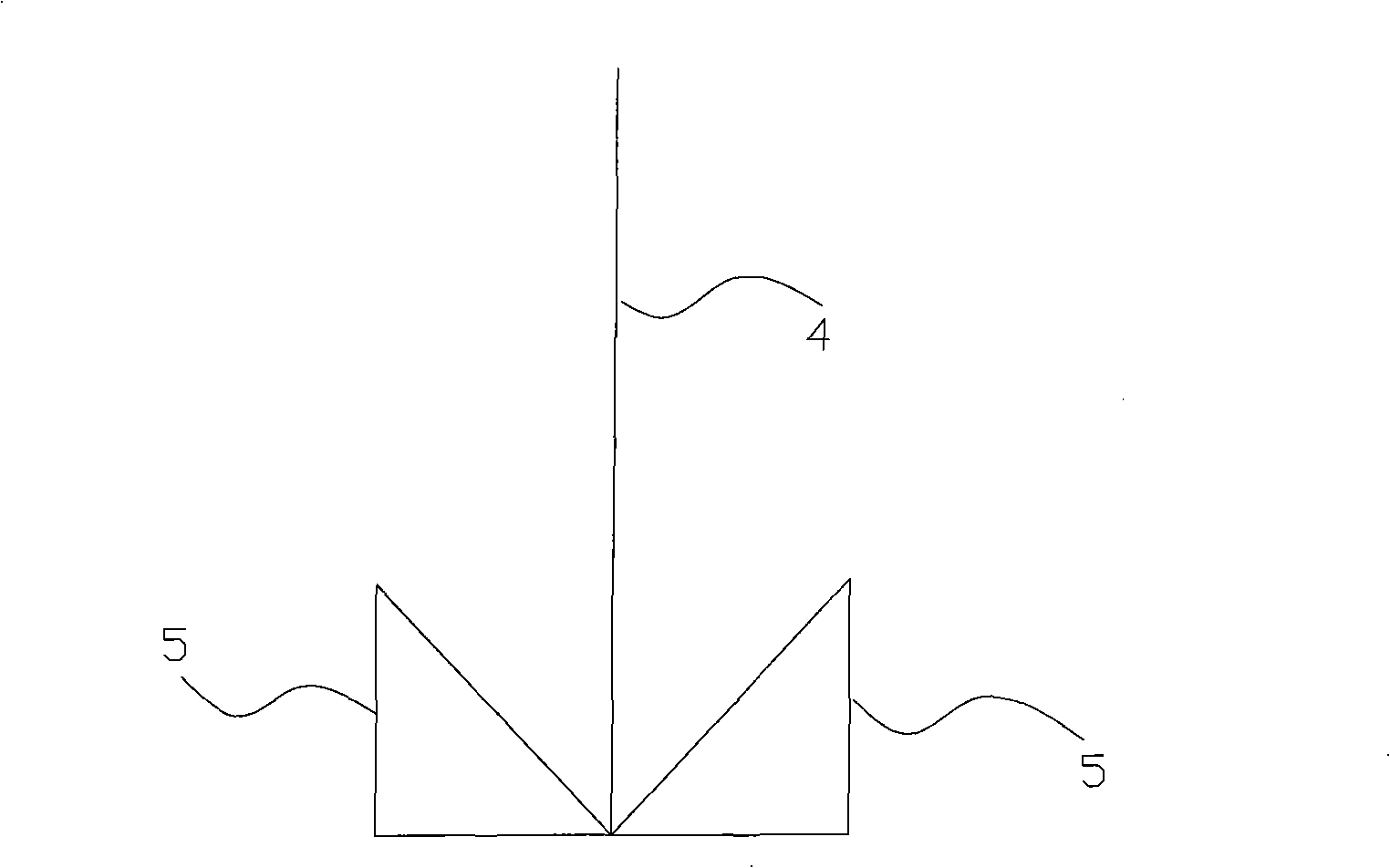

[0021] Such as Figure 1 to Figure 6 As shown, an electroplating device for a printed circuit board is provided with two opposite anodes 2 in the electroplating tank 1, and the two anodes 2 are electrically connected to the positive electrode, and the two anodes 2 are arranged between the two anodes 2 in the electroplating tank 1 There is a floating tank 3, on which a circuit board 4 connected to the negative electrode is arranged; the floating tank 3 includes two side plates 5, the circuit board 4 is positioned between the two side plates 5, and Both are provided with side plate holes 6.

[0022] Wherein, the electroplating tank 1 is provided with a flybar 10 (i.e. a fixed beam), and a hanger 9 is arranged on the flybar 10, and a plurality of circuit boards are suspended on the hanger 9; two side plates 5 are parallel to the circuit board 4 , the side plate holes 6 on each side plate 5 are multiple to form a row of holes, and among the side plate holes 6 on the side plates 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com