Wafer surface treatment device

A surface treatment device, wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of the wafer cannot be rotated, the wafer is damaged, difficult to clean horizontally, electroplating or etching, etc., to reduce Risk of damage to wafer, uniform etching, ease of use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

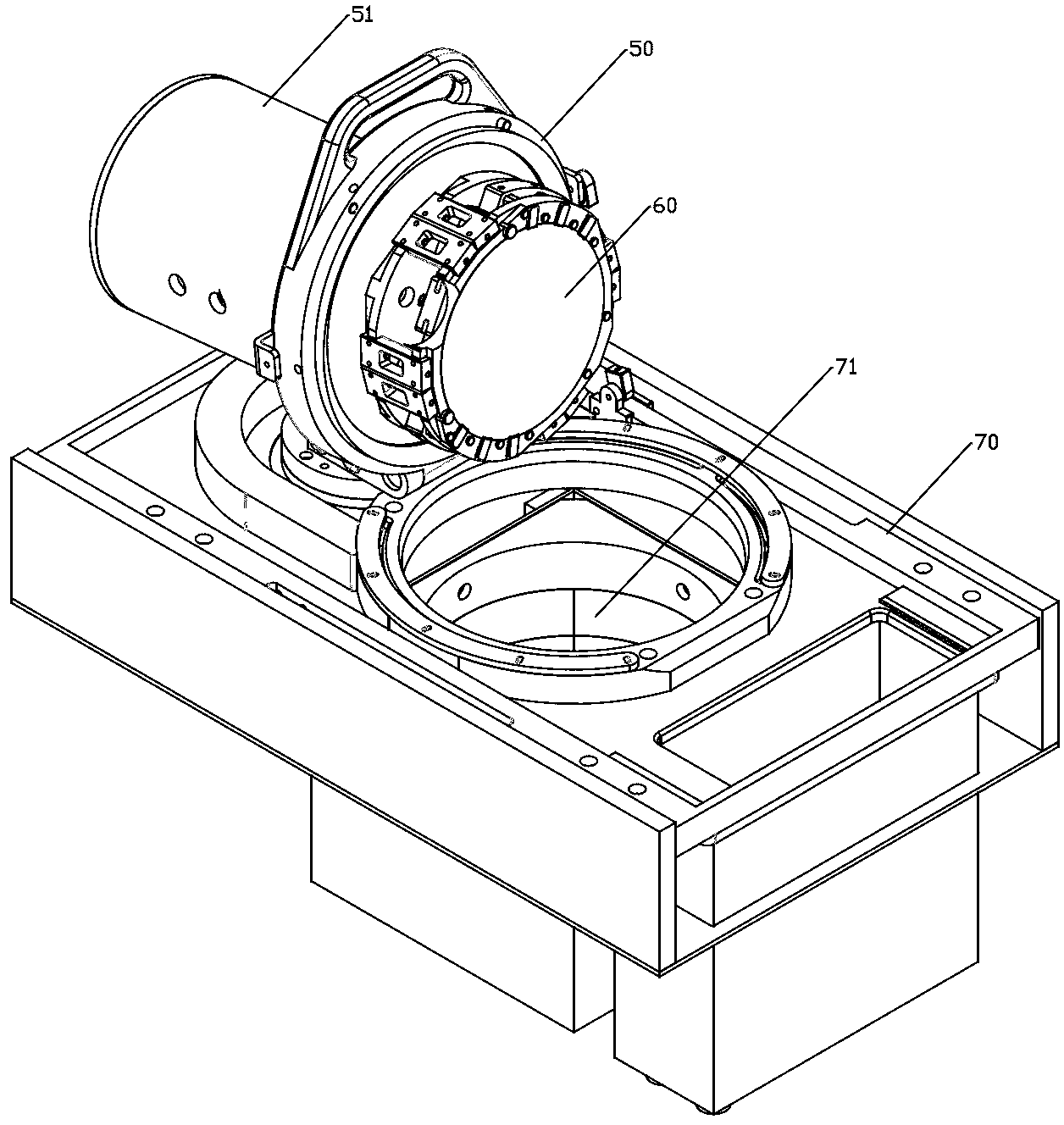

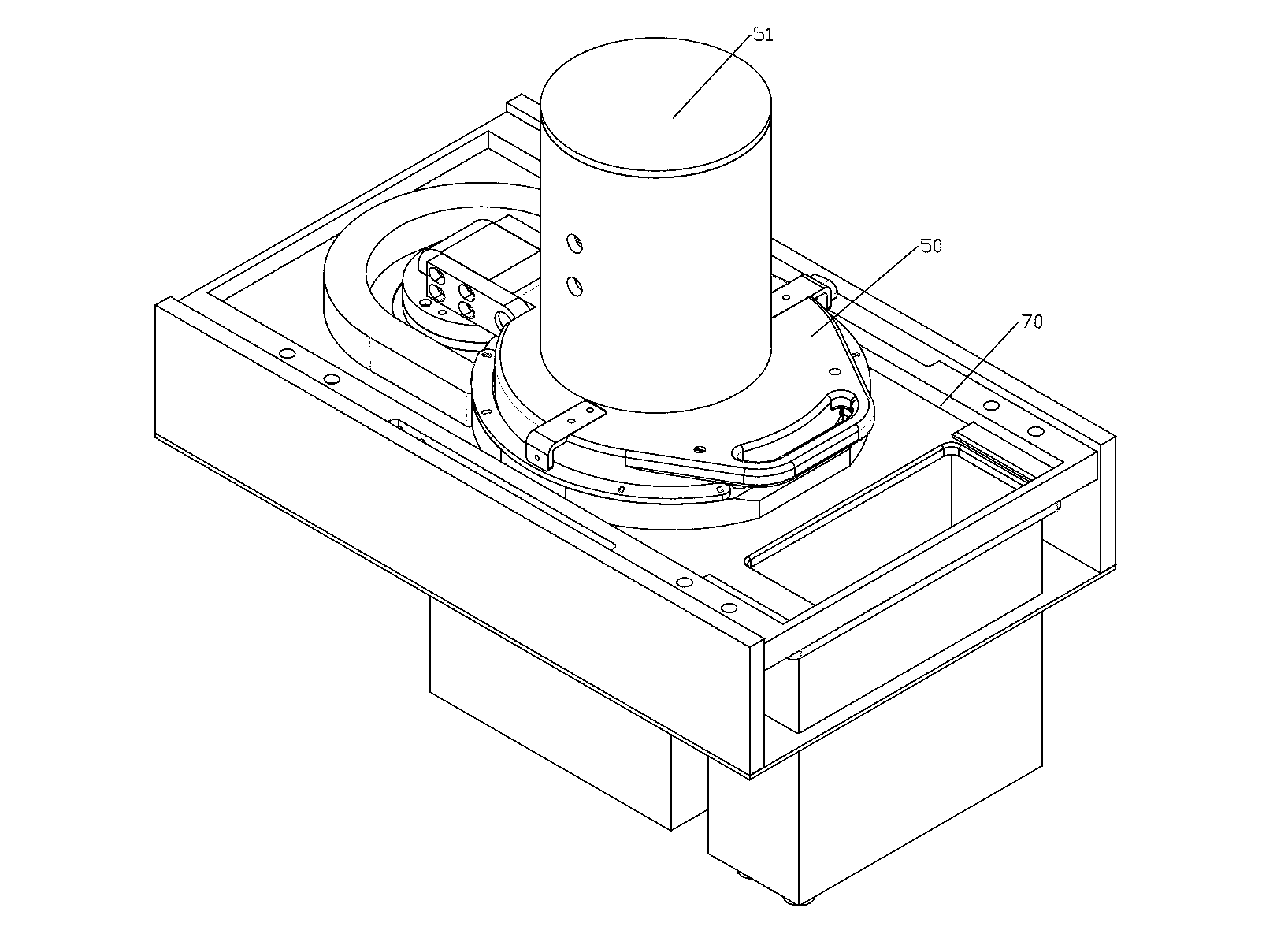

[0040] Such as figure 1 , figure 2 As shown, the wafer surface processing device includes a wafer clamping and rotating device and a tank 70 . The tank body 70 is provided with a tank cavity 71 . The tank cover 50 is hinged on the tank body 70 and is reversibly installed. After the wafer 60 is fixed, turn over the slot cover 50 to make it as Figure 6 As shown in the sealed tank cavity 71 , cleaning water enters from the lower end of the tank body 70 and flows upward to the position where it contacts the wafer 60 to clean the wafer 60 . During the cleaning process, the wafer clamping and rotating device drives the wafer 60 to rotate.

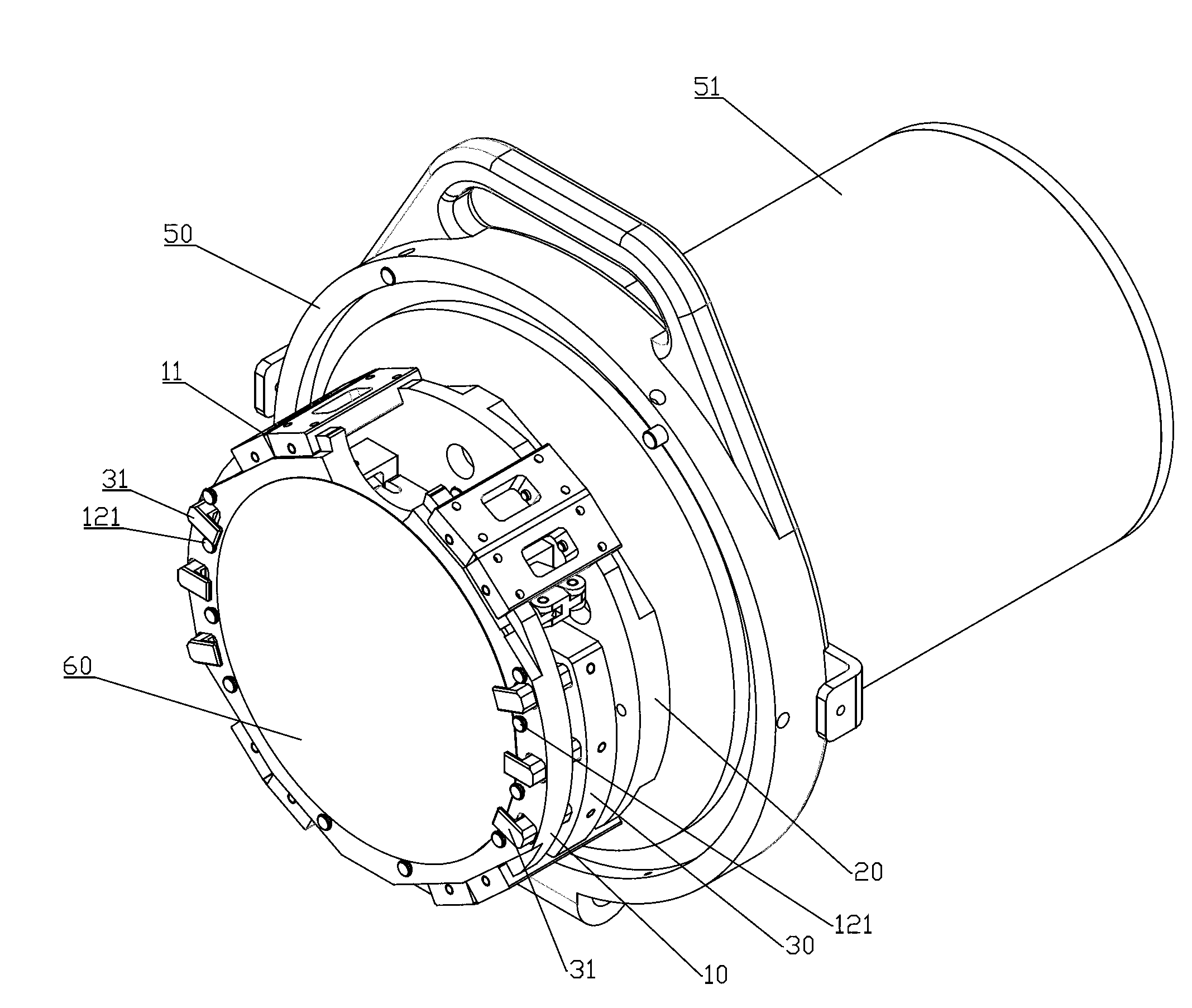

[0041] Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the wafer holding and rotating device includes a slot cover 50 . A casing 51 is mounted on the slot cover 50 . The casing 51 has a cavity 52 . A cylindrical bracket 521 and a motor 54 are disposed in the cavity 52 . The cylinder 53 includes a housing 531 , a pis...

Embodiment 2

[0046] The difference between this embodiment and Implementation 1 is that, as Figure 7 As shown, no sleeve 55 is provided. The housing 531 of the air cylinder is rotatably mounted on the tank cover 50 and connected to the upper base plate 30 after passing through the tank cover 50 . The piston plate 56 is movably disposed in the casing 531 . An O-ring 58 is disposed between the housing 531 and the slot cover 50 . The rest of the structure is the same as in Implementation 1.

[0047] The compression spring 57 in Embodiment 1 and Embodiment 2 can also be arranged between the support plate 30 and the lower base plate 10 , with one end abutting against the support plate 30 and the other end abutting against the lower base plate 10 . Of course, the compression spring 57 can also be replaced by a tension spring, the tension spring is arranged between the upper base plate 20 and the support plate 30 , and its two ends are respectively connected with the upper base plate 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com