Hanging tool for wafer electroplating

A technology for wafers and plated holes, which is applied to circuits, electrolytic components, electrolytic processes, etc., can solve problems such as large cost increases, complicated operating procedures, and time-wasting, and achieve simple and convenient locking methods, reduce operating procedures, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

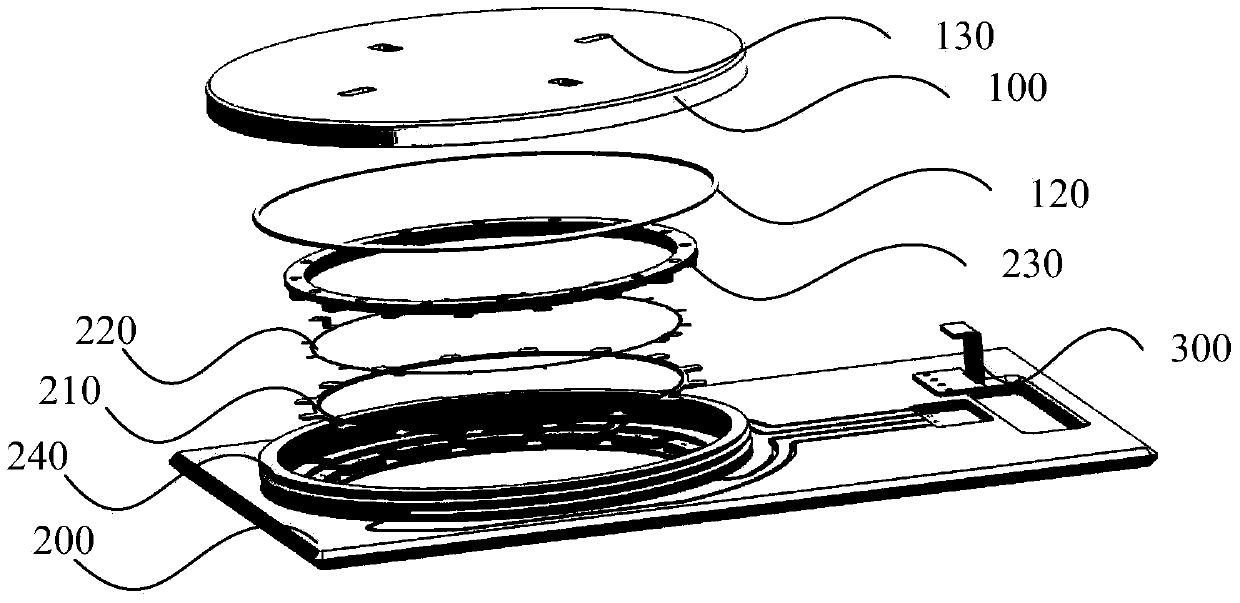

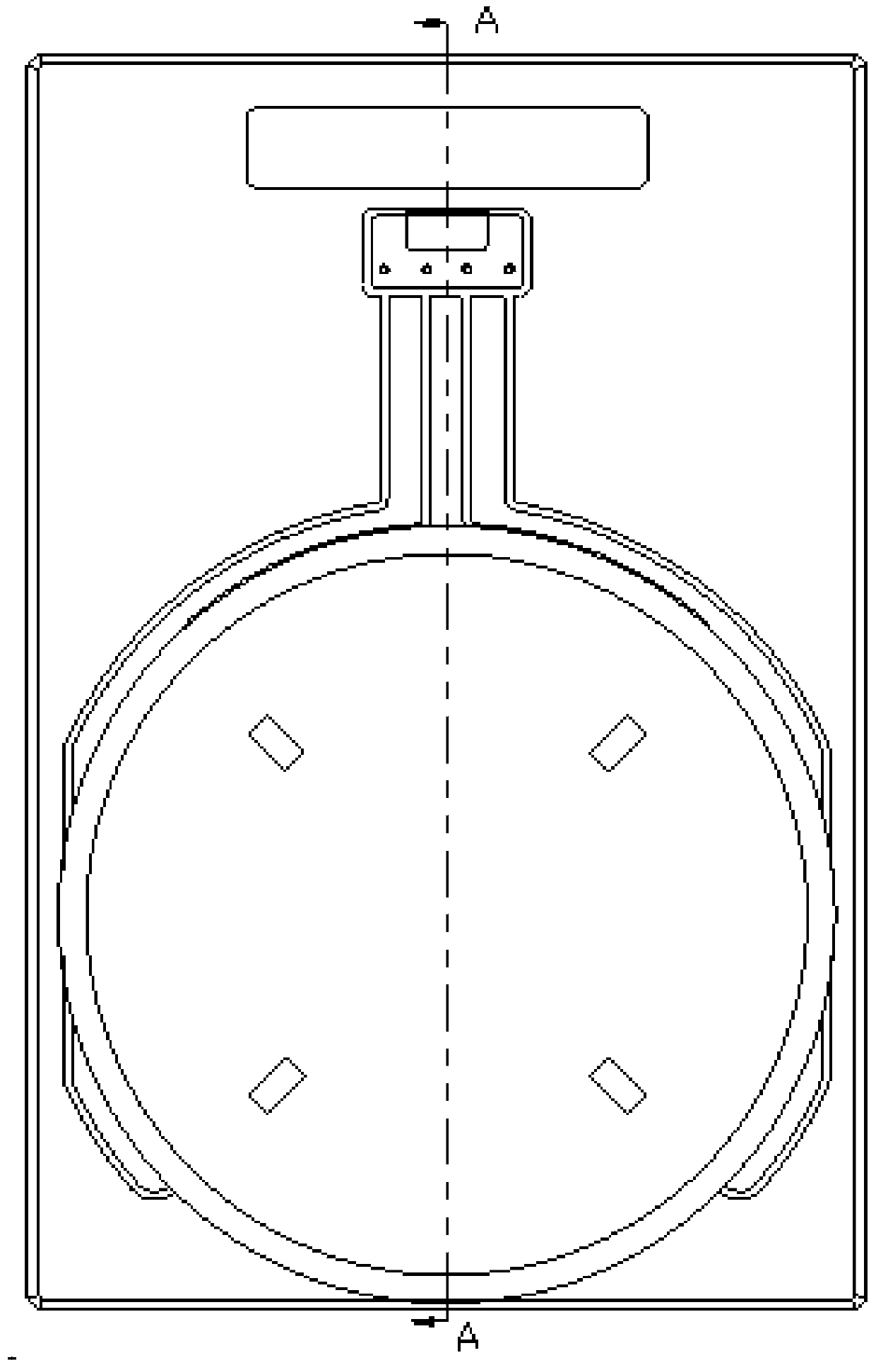

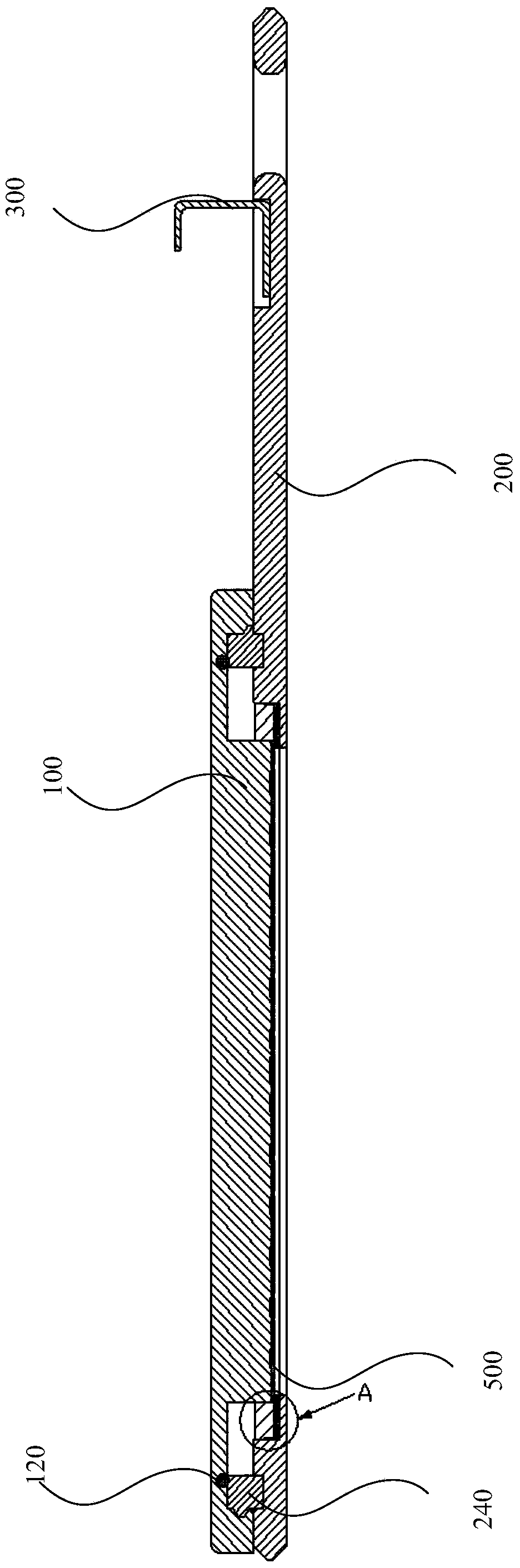

[0048] Embodiment 1 provides a hanger for wafer electroplating, such as Figure 1-9As shown, it includes an upper cover 100 and a lower plate 200. The upper cover 100 is also provided with an upper cover sealing ring 120; the lower plate 200 is provided with a wafer tank, a wafer tank wall 240, a sealing assembly, a metal conductive ring 220, Conductive copper plate 300, conductive copper plate groove 310, wire groove 400, electroplating hole 260, hanging part 280, etc.

[0049] The inner wall of the upper cover 100 is provided with an internal thread, and the outer wall of the wafer tank is provided with an external thread engaged with the internal thread. The upper cover 100 and the wall 240 of the wafer tank can be locked by rotating 90-3600 degrees. The wafer tank wall 240 and the lower plate 200 are fixedly connected or detachably connected. In this embodiment, the wafer tank wall 240 and the lower plate 200 are detachable structures;

[0050] A plating hole 260 is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com