Method for machining semimetal blind hole with aspect ratio greater than 1

A processing method and semi-metal technology, which is used in the processing of insulating substrates/layers, the formation of electrical connection of printed components, and electrical components, etc. Scrap and other issues to avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

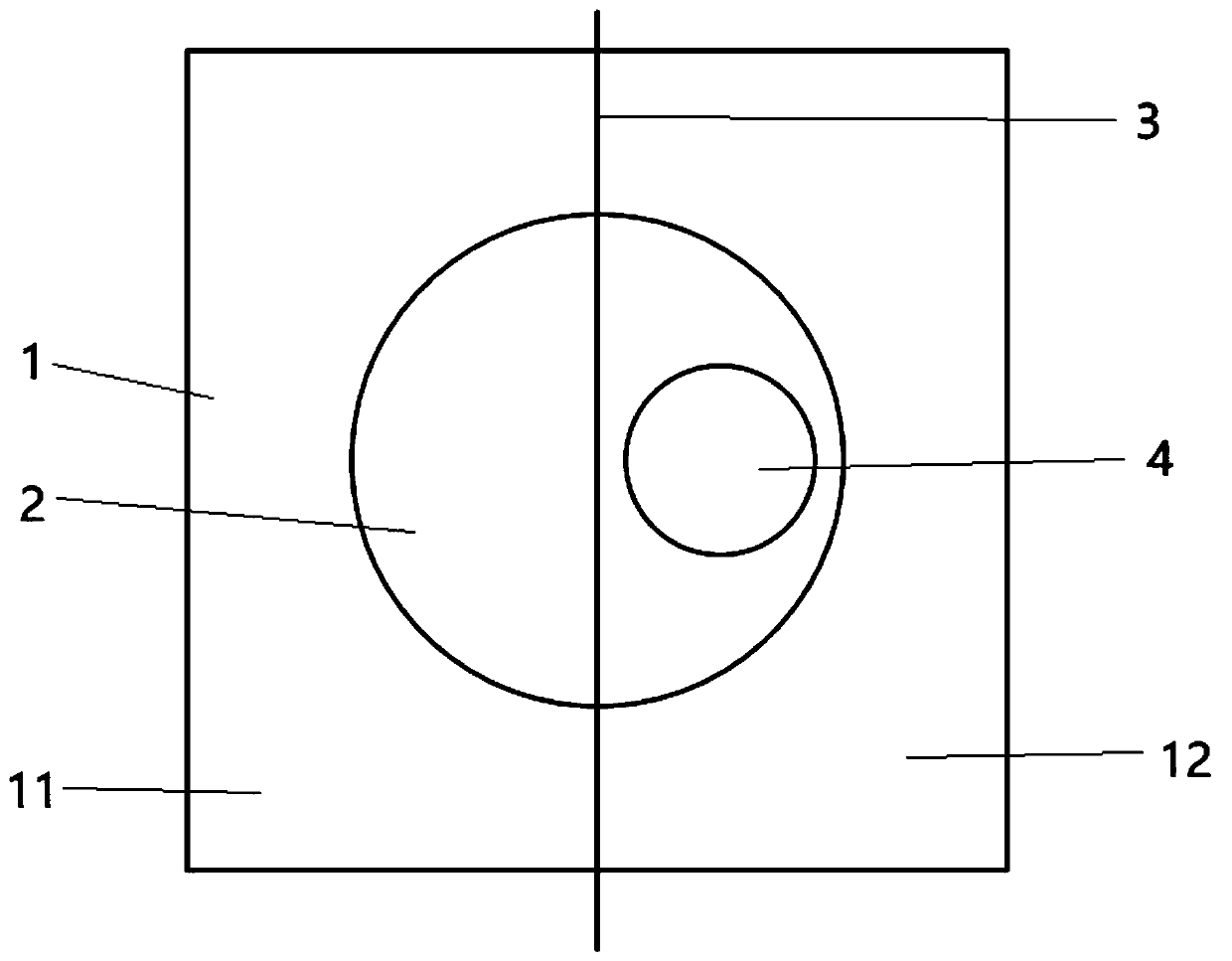

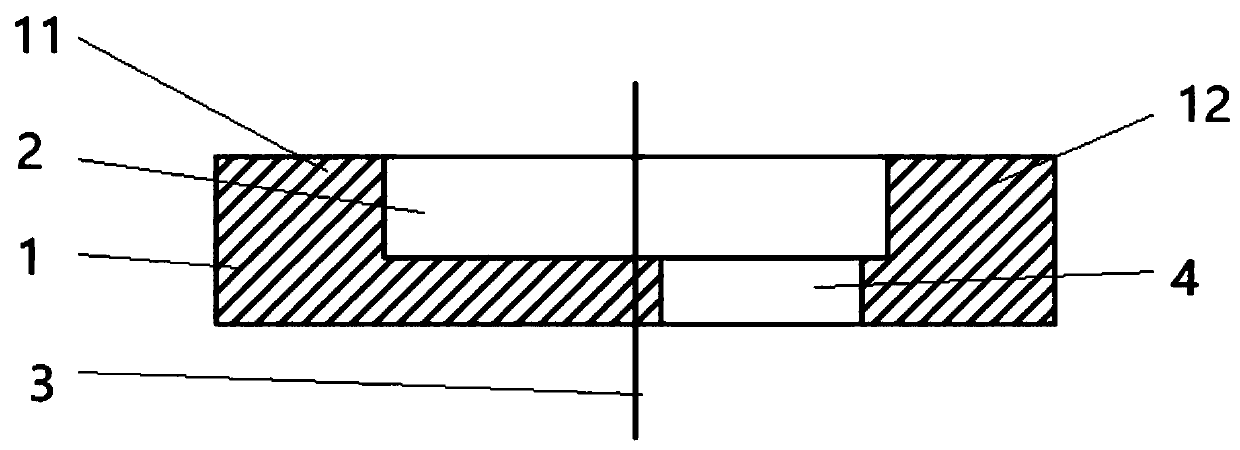

[0028] Such as Figure 1-2 As shown in , an embodiment of the present invention provides a method for processing a half-metal blind hole with an aspect ratio greater than 1, comprising the following steps:

[0029] S1. Drill blind grooves, select a suitable plate 1, drill blind holes 2 on the surface of the plate 1, and make the hole depth greater than the hole diameter;

[0030] S2. Drill diversion hole 4, use the diameter of blind hole 2 as dividing line 3 to divide its two sides into reserved area 11 and cutting area 12 respectively, drill a through hole at the bottom of the hole on one side of cutting area 12, and the through hole does not cross the dividing line between the two areas;

[0031] S3, copper immersion electroplating, the whole plate 1 is subjected to chemical copper immersion and electroplating process, and a uniform electroplating layer is formed on the surface of the plate 1 and the inner wall of the blind control;

[0032] S4, milling and cutting, the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com