Adjustable spanner

An adjustable wrench technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of workpiece surface damage, complex process, low application rate, etc., and achieve the effects of prolonging service life, convenient portability, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

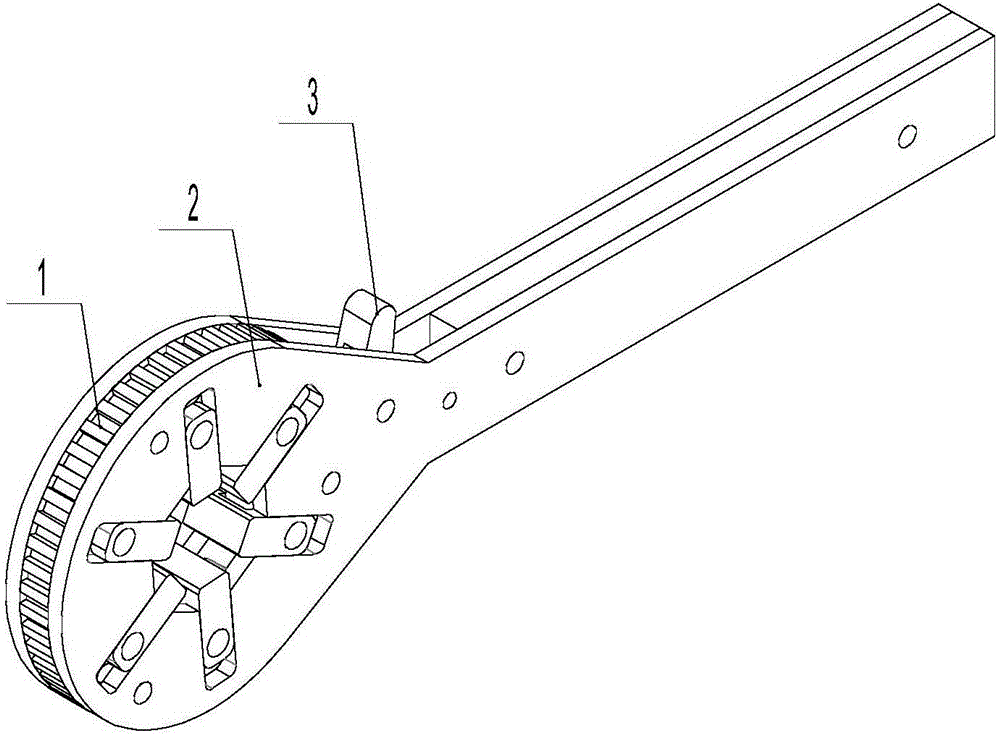

[0021] like figure 1 As shown, the adjustable wrench includes a wrench body 2, and the wrench body 2 is provided with a moving toothed plate 1 and a pawl 3 that cooperate with each other;

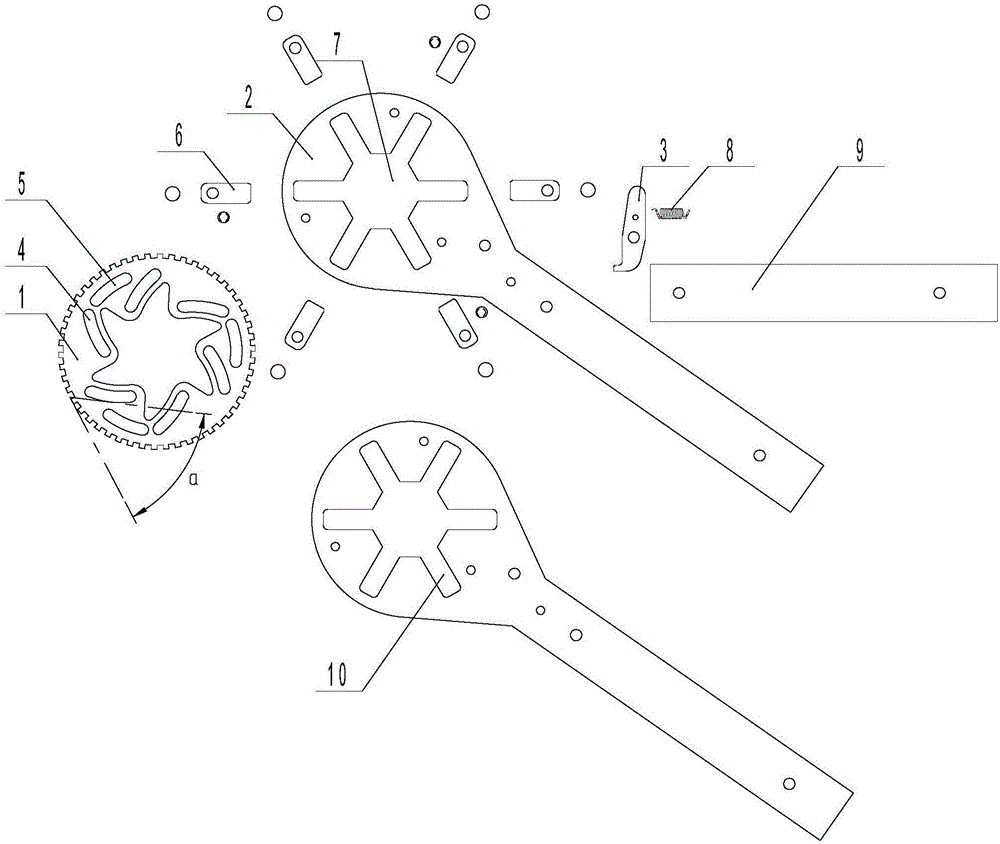

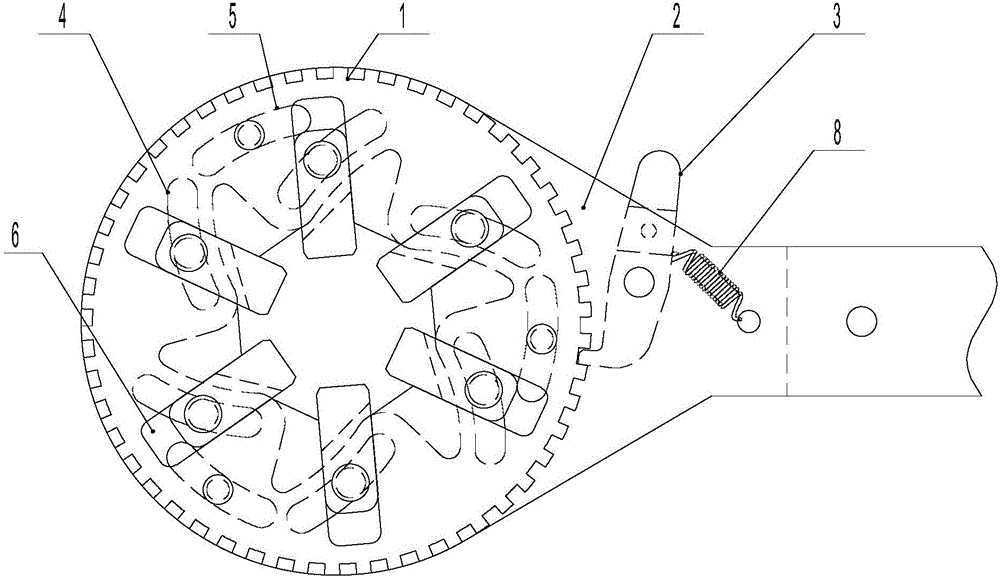

[0022] like figure 2 and image 3 As shown, the wrench body 2 is provided with sleeve holes 7 and evenly distributed grooves 10, and the wrench body 2 is provided with a movable toothed disc 1 and a pawl 3 that cooperate with each other, and the movable toothed disc 1 is provided with grooves 10 is fitted with an arc-shaped groove A4, and a sliding block 6 is provided in the groove 10, and the sliding block 6 passes through the arc-shaped groove A4 through a pin shaft and is flexibly connected with the moving toothed disc 1, and the tangent line at any point on the circumference of the moving toothed disc 1 The included angle a with the tangent line on the outer circumference of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com