Clamp for processing vertical positioning surface of tail wing of airplane

A vertical stabilizer and empennage technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of non-arbitrary adjustment, difficulty in design and manufacture, and low efficiency of manual operation, so as to achieve flexible and stable adjustment, Excellent clamping effect and good attitude adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

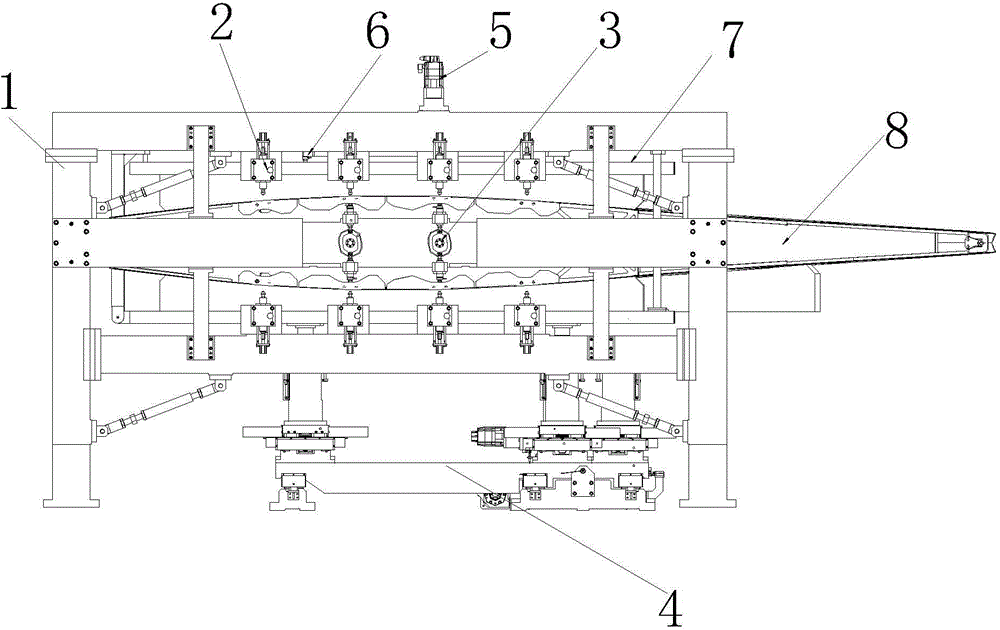

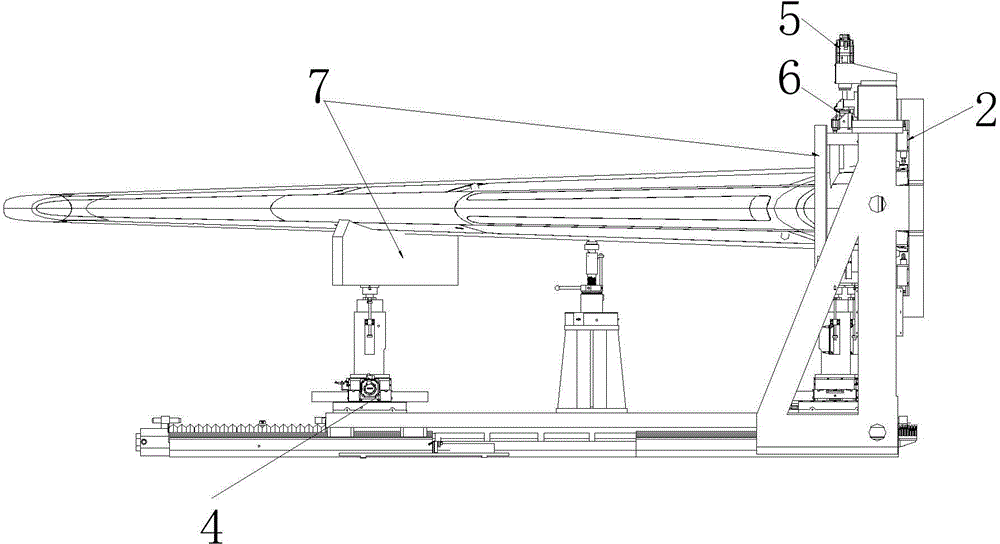

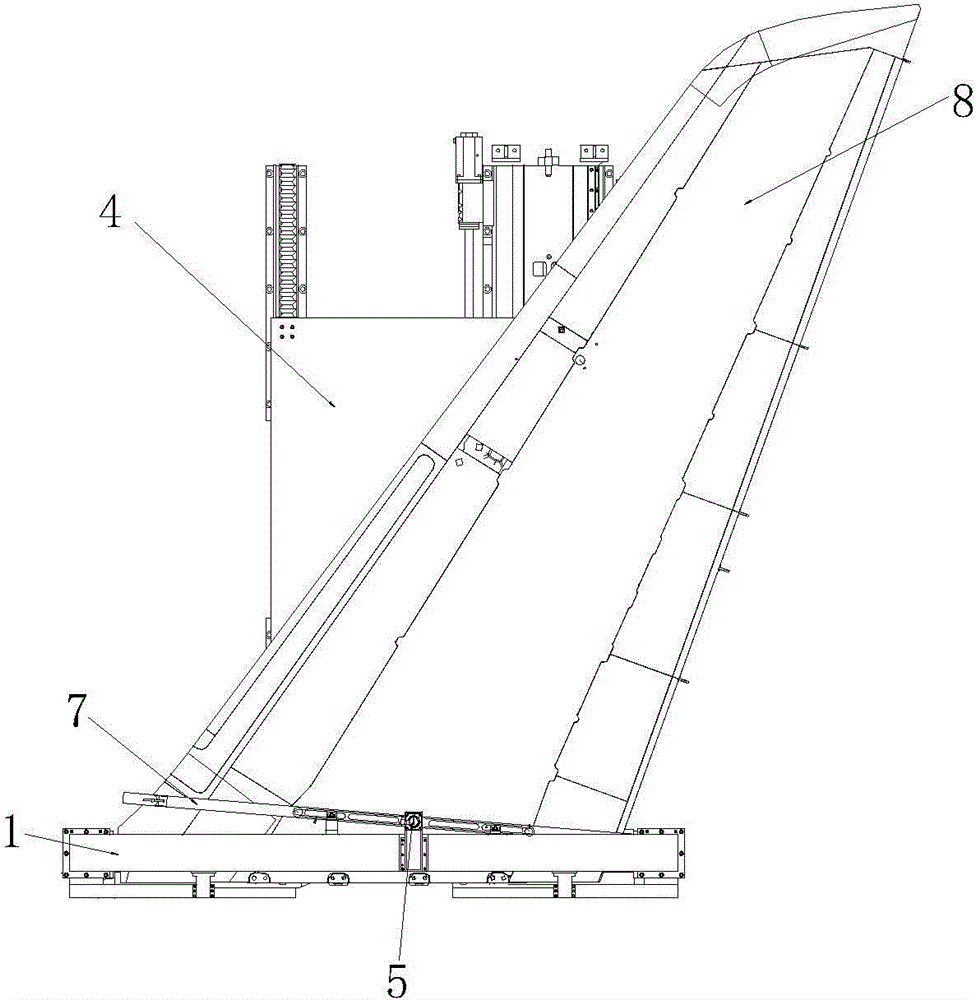

[0032] like Figure 1~3 As shown, the fixture used for processing the vertical stabilizer of the aircraft empennage includes a bracket 1 and an attitude adjustment positioning device 4 located on one side of the bracket for providing positioning support for the middle and tail of the empennage. The upper and lower beams of the bracket 1 are equipped with multiple In the external support device 2 that is pressed against the head outside of the empennage 8, a plurality of internal support devices 3 for compressing the inside of the empennage head are installed on the middle beam of the support 1, and are also installed on the support 1 for empennage Head fixed main clamping mechanism 6. The external supporting devices installed on the upper cross beam of the support are opposite to the external supporting devices installed on the lower cross beam, and the internal supporting devices installed on the middle cross beam of the support are opposite to each other.

[0033] Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com