An automatic welding device for shelf beams and hanging pieces and application method thereof

An automatic welding and shelf beam technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of continuous feeding of corner pieces, manual placement of hanging corners, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

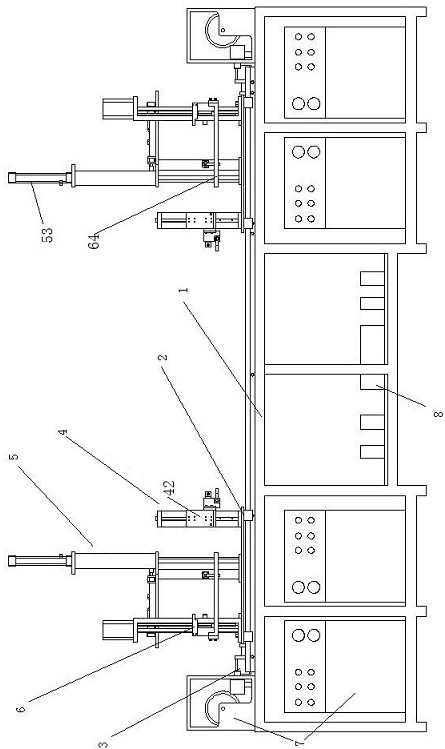

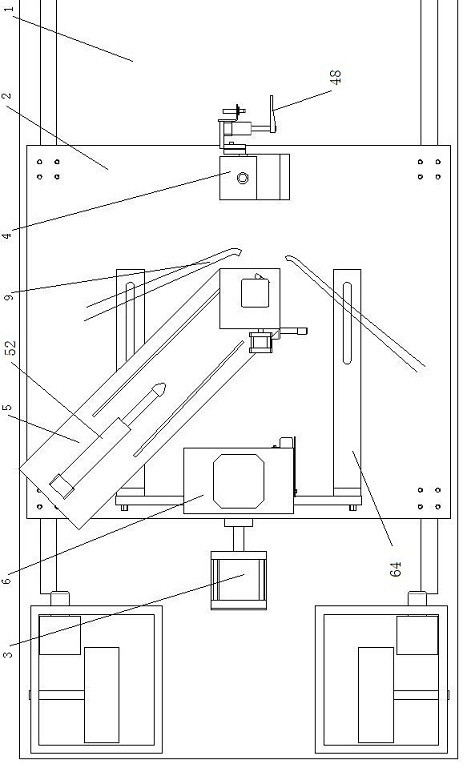

[0039]Referring to the accompanying drawings, an automatic welding device for shelf beams and hanging pieces of the present invention includes a machine base 1, a mobile platform 2, a clamping cylinder 3, a beam positioning mechanism 4, a hanging piece feeding mechanism 5, a welding mechanism 6, a welding machine 7, Control circuit (mechanism) 8, welding torch 9.

[0040] The mobile platform 2, the clamping cylinder 3, the welding machine 7 and the control circuit 8 are arranged on the machine base 1; the beam positioning mechanism 4, the hanger feeding mechanism 5, and the welding mechanism 6 are arranged on the mobile platform 2; 3 cylinders are connected for horizontal movement.

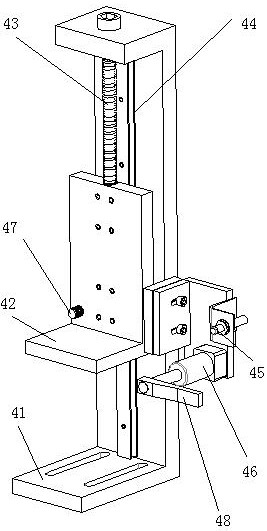

[0041] Crossbeam positioning mechanism 4 comprises base crossbeam positioning base 41, lifting platform 42, lifting bolt 43, guide rail 44, induction switch one 45, pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com