Molded case circuit breaker operating mechanism buckle carrying device

A technology of molded case circuit breaker and operating mechanism, applied in the direction of protection switch operation/release mechanism, circuit, electrical components, etc., can solve the problems of wear, mechanism can not work normally, power failure accident, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

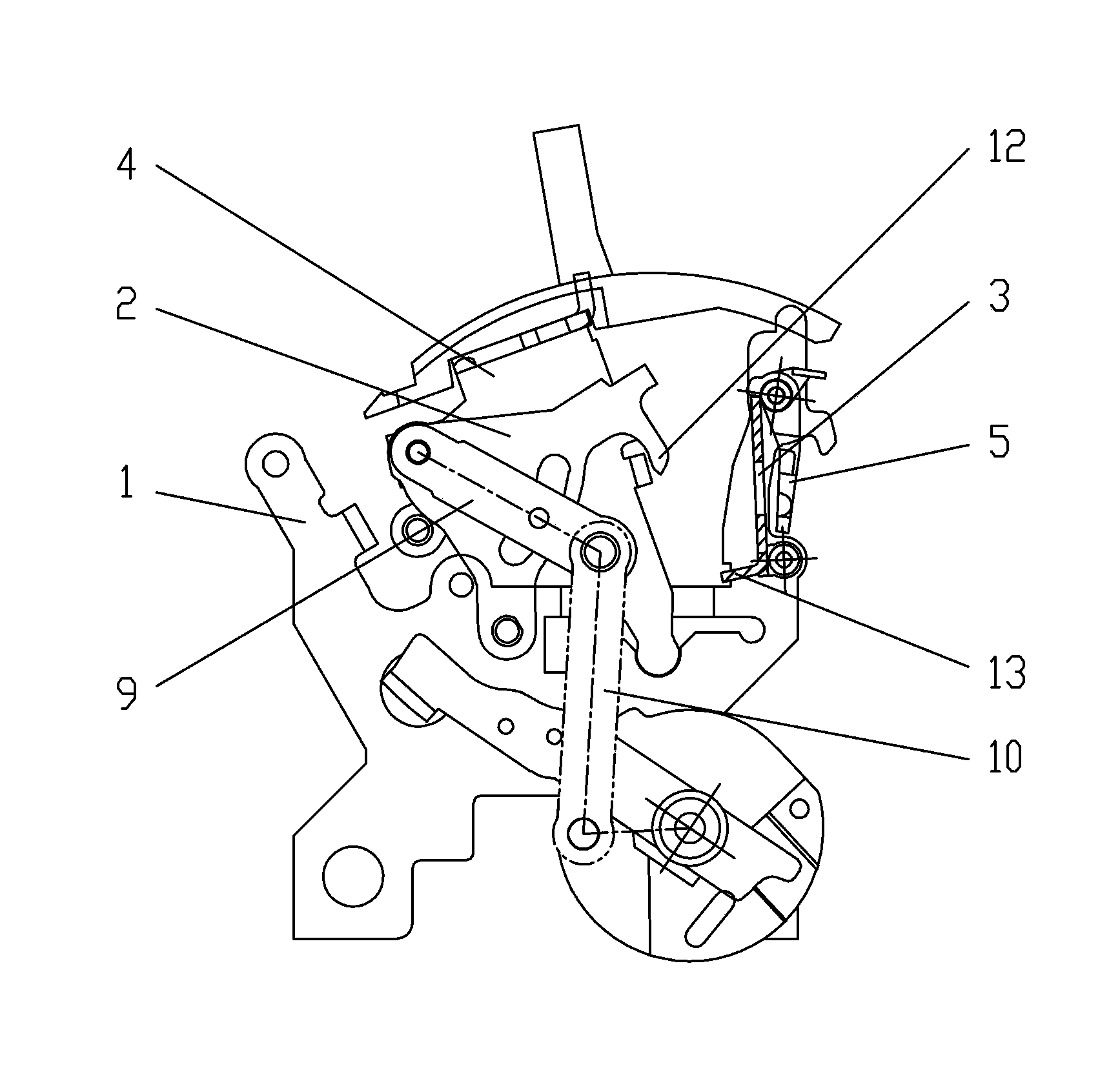

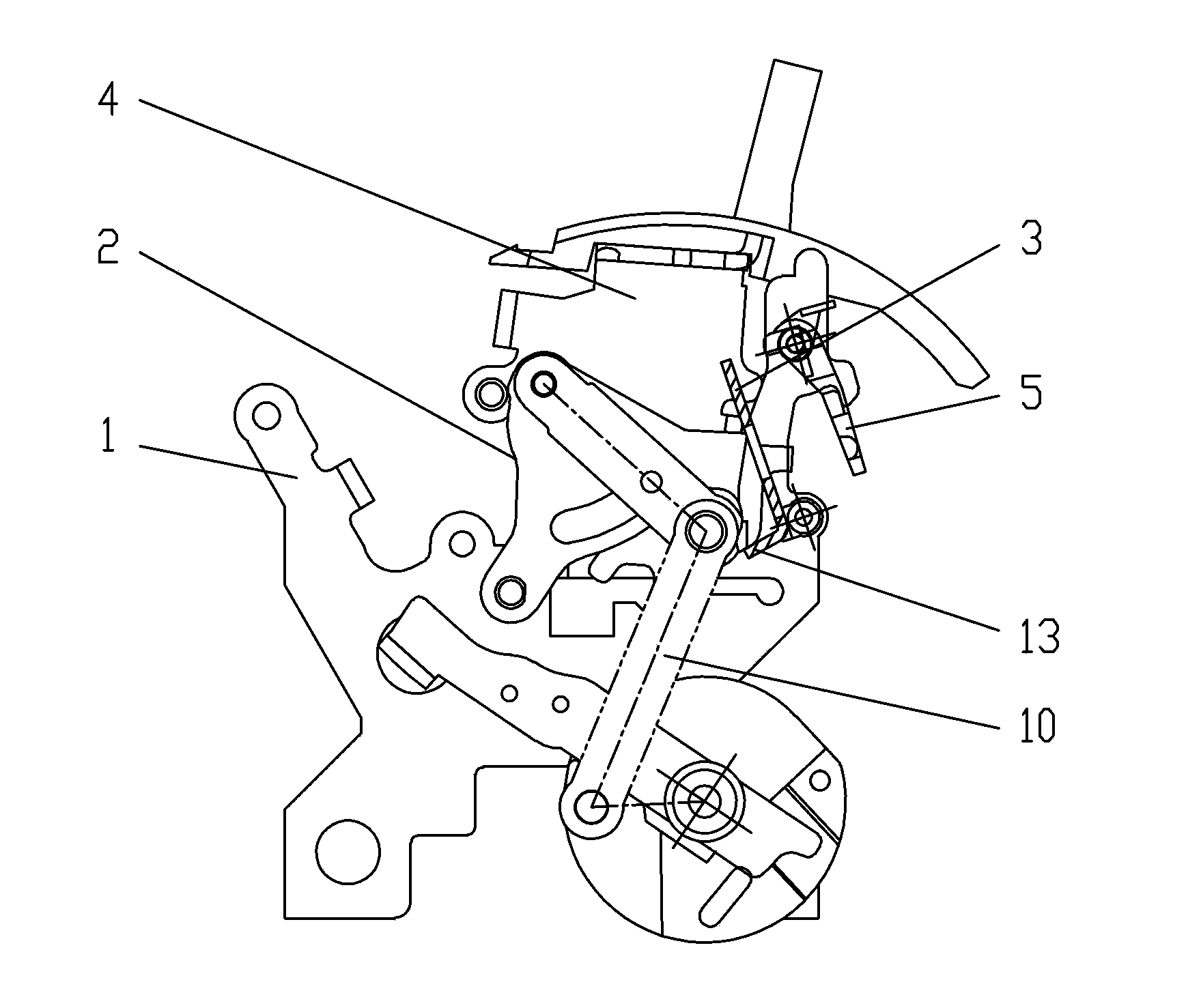

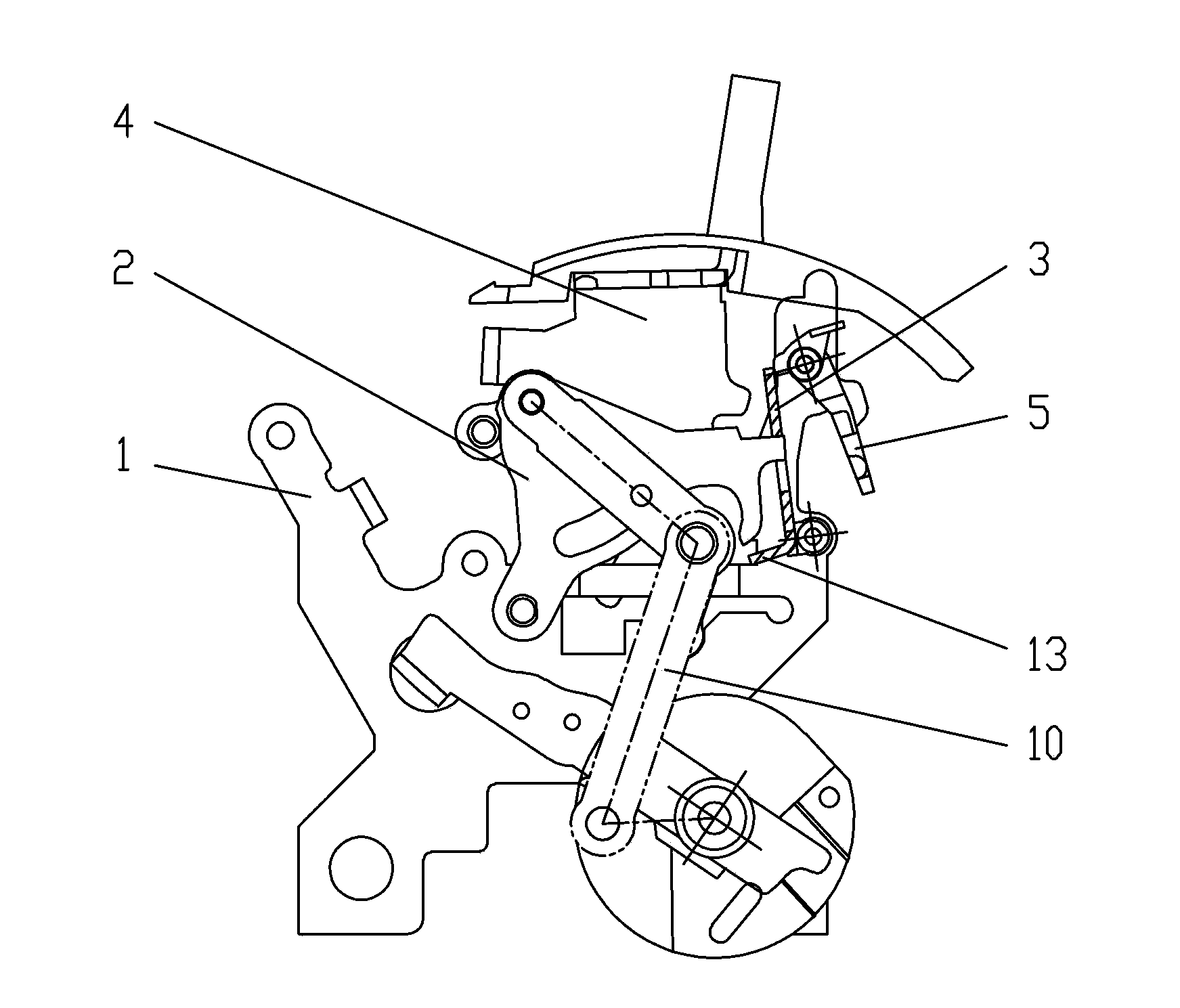

[0014] As shown in the figure, the buckle carrying device of the operating mechanism of the molded case circuit breaker of the present invention consists of a mechanism bracket 1, a jumper 2, a lock 3, a lever 4, a draw bar 5, a tension spring 6, a lock torsion spring 7, and a draw bar The torsion spring 8, the shaft 11, the upper link 9 and the lower link 10 are assembled, the jumper 2 is fixed in the middle of the mechanism bracket 1, the lock 3 and the drawbar 5 are installed in the mechanism bracket by the shaft 11, and the lock shaft Lock buckle torsion spring 7 is installed, and draw bar torsion spring 8 is installed on the draw bar shaft, provides power respectively, jumper 2 rotates under the drive of lever 4, and one end of upper connecting rod 9 is riveted on the jumper 2, and one end is connected with the lower Connecting rod 10 is connected, and extension spring 6 is installed in the middle connection part, and the upper end of extension spring 6 is hooked on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com