Centrifuge used in multi-parameter complex test environment

A compound test and multi-parameter technology, which is applied in the field of centrifuges, can solve the problems of difficult installation and compound test, etc., and achieve the effect of small space occupation of the machine body, reduction of mass and moment of inertia, and increase of bearing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

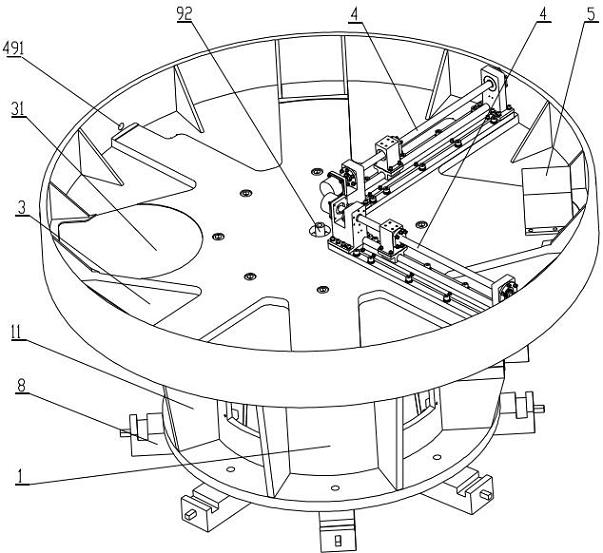

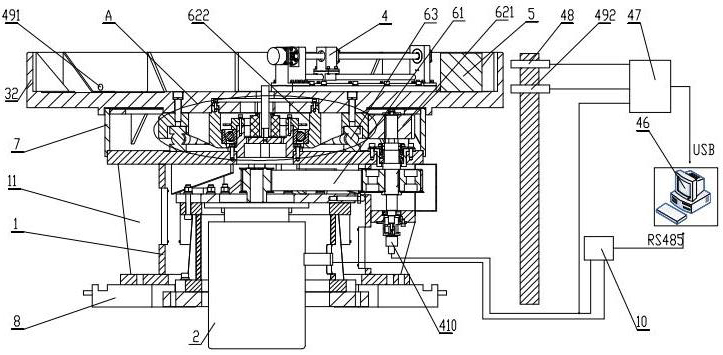

[0049] refer to Figure 1-9

[0050] A centrifuge used in a multi-parameter composite test environment, including a base 1, a drive motor 2 fixed on the base, an arm 3 carrying a composite parameter test device, and transmitting the power of the drive motor 2 to The transmission mechanism of the machine arm 3, the static balance mass 5 fixed on the machine arm and the dynamic balance actuator 4 installed on the machine arm 3 to realize self-adaptive dynamic balance;

[0051] Described machine arm 3 is disc-shaped, and described machine arm 3 is evenly provided with web 31, and described composite parameter test device is installed on described web 31;

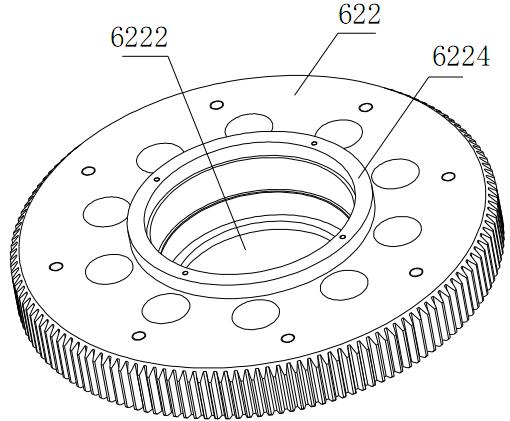

[0052] The transmission mechanism includes a belt transmission mechanism 61 connected to the output shaft of the drive motor 2 and a gear mechanism connected to the machine arm 3; The gear 621 and the large gear 622 affixed to the machine arm 3;

[0053] The upper surface of the large gear 622 is connected with the bottom su...

Embodiment 2

[0064] refer to Figure 9

[0065] The difference between this embodiment and Embodiment 1 is that: the through hole 6222 of the large gear 622 is provided with a rotary air supply for supplying air to each test device, and the air pipe on the arm can follow the rotation of the arm 3 Mechanism, the rotary air supply mechanism includes a hollow conductive slip ring 91 and a rotary joint 92 connecting the gas delivery pipe with an external air source, and the rotary joint 92 is located inside the conductive slip ring 91;

[0066] The fixed ring of the conductive slip ring 91 is affixed to a mounting base 93, the mounting base 93 is fixed to the base 1, the moving ring of the conductive slip ring 91 is connected to the large gear 622 Linkage; the moving ring of the conductive slip ring 91 is fixedly connected to a rotating flange 94, and the rotating flange 94 is fixedly connected to the large gear 622;

[0067] The fixed coil of the rotary joint 92 is fixedly connected to the ...

Embodiment 3

[0071] refer to Figure 10 , 12 、13

[0072] The difference between the present invention and the second embodiment is that the dynamic balance actuator 4 includes a dynamic balance execution unit that adjusts its dynamic balance mass 44 along two directions, and the dynamic balance execution unit includes The base 41 on the machine arm 3, the guide rail 42 fixed on the base 41, the slider 43 slidingly connected with the guide rail 42 and the slider 43 that pushes the slider 43 to reciprocate along the guide rail Dynamic balance transmission mechanism, the dynamic balance mass block 44 is affixed to the slider 43, and the two adjustment directions of the dynamic balance execution unit are vertical;

[0073] Described machine arm 3 is provided with collecting device that collects the periodical vibration response of machine arm 3 caused by unbalance, and described collecting device can obtain the amplitude and phase of the vibration response caused by different balance quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com