3D printing machine with inclinable working platform

A technology of 3D printers and working platforms, which is applied in the direction of additive processing, etc., can solve problems such as the interference of the z-axis degree of freedom of the working platform, and achieve the effects of avoiding uneven drawing and improving printing accuracy and printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

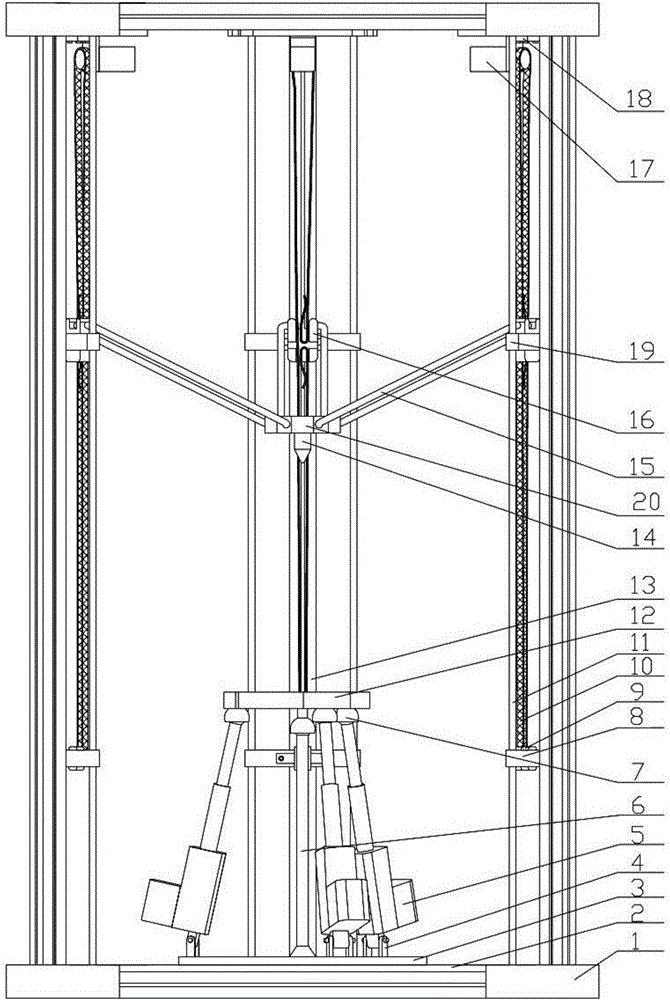

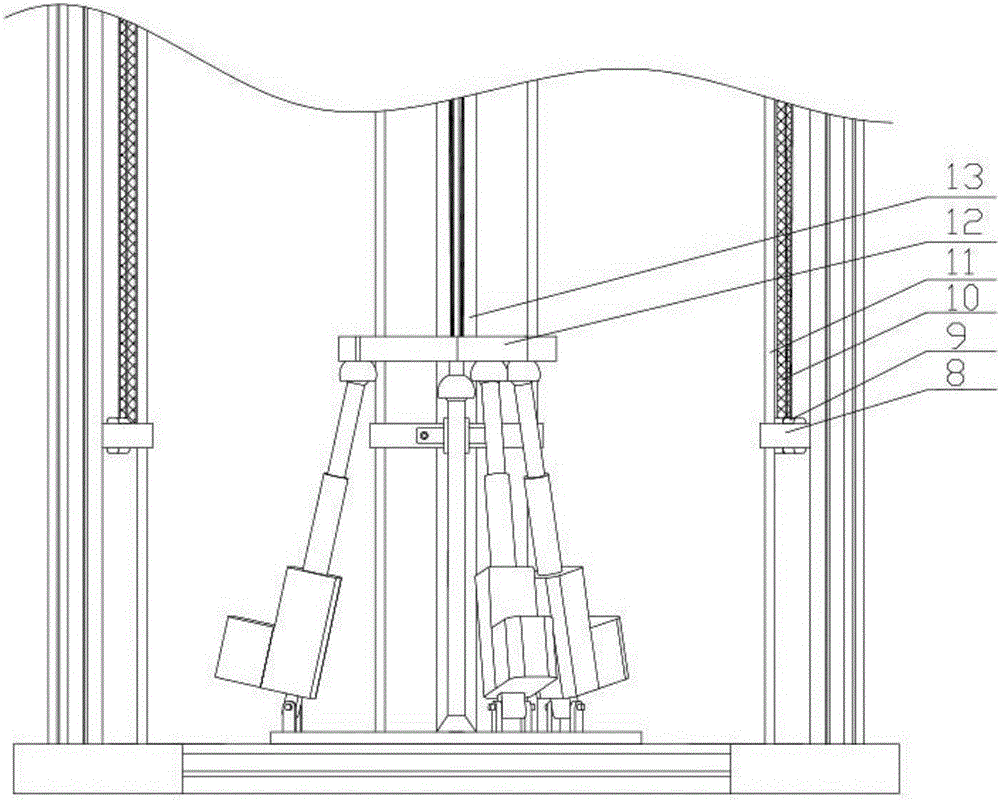

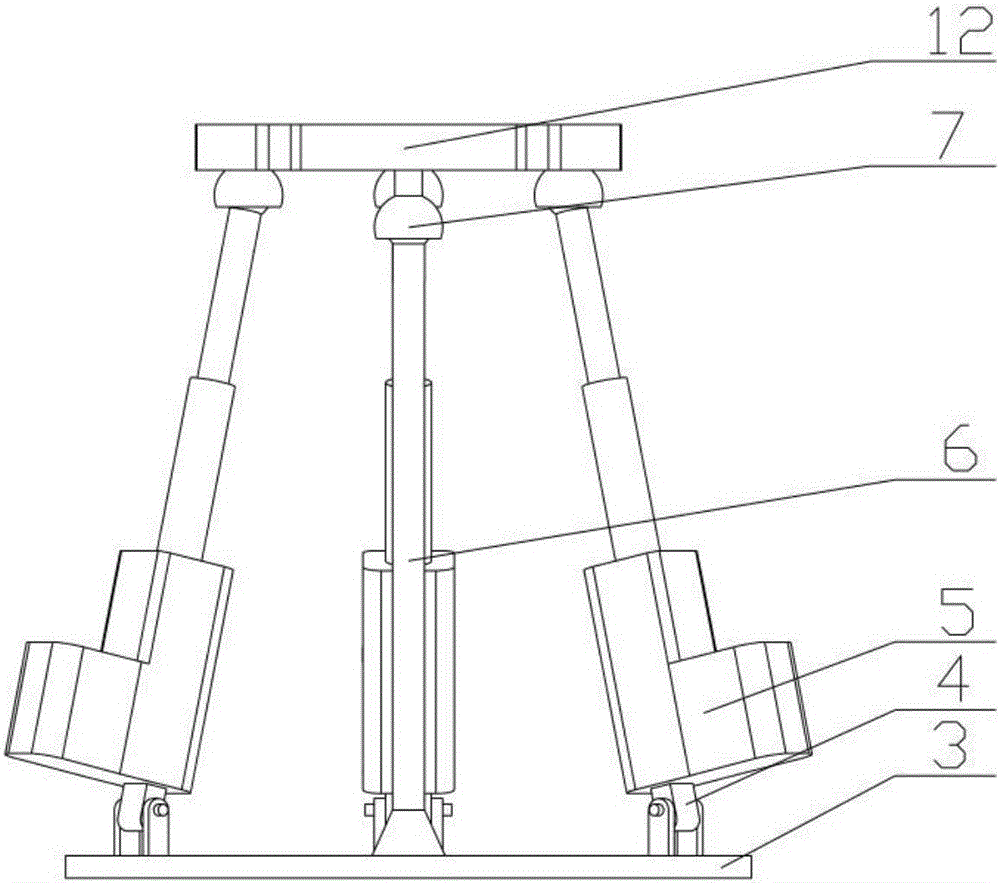

[0026] Such as figure 1 with figure 2 As shown, a 3D printer with a tiltable working platform in this embodiment is mainly composed of a triangular prism frame composed of a base 1 and a bracket 13, a nozzle structure 14, a nozzle movement mechanism, a work platform 12 and a work platform movement mechanism;

[0027] There are two bases 1, located at the top and bottom of the frame respectively; the nozzle movement mechanism includes a lower block 8, a stop block 9, a synchronous belt 10, a feed rod 11, a support rod 15, a clamp block 16, a motor 17, and an upper slider 19 and nozzle platform 20. There are six light rods 11, which are respectively fixed between the two bases 1;

[0028] Such as figure 1 with Figure 4 As shown, the number of clamp blocks 16 and stop blocks 9 is three, which are respectively located at the top and bottom of each side of the triangular prism frame; the clamp blocks 16 on each side are fixed on the upper slide block 19, and the stop blocks 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com