Universal large-aperture rigid bearing-type quick reflecting mirror

A mirror, carrying technology, used in installation, optics, instruments, etc., can solve problems such as poor versatility and difficulty in miniaturization, and achieve the effect of convenient installation and connection, protection of internal precision structure, and reduction of structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

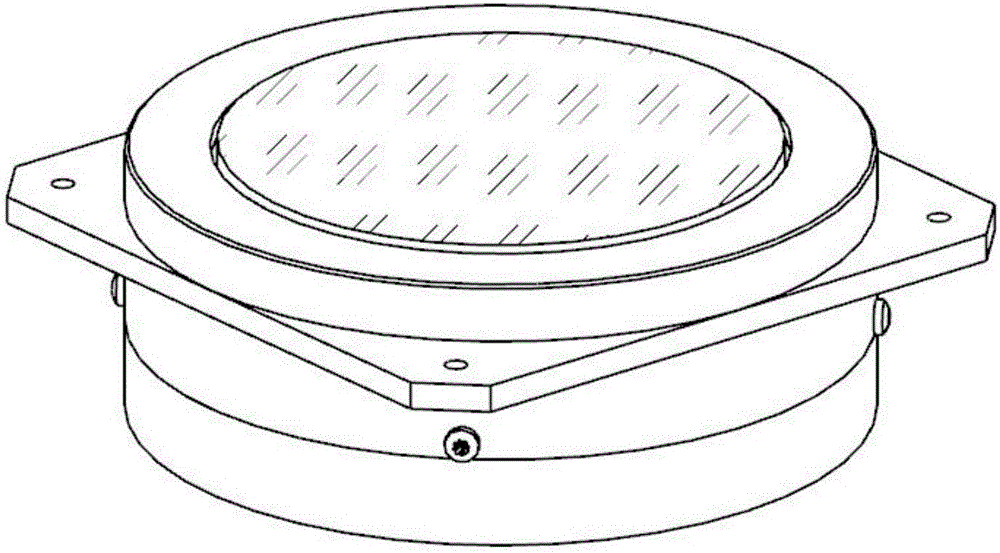

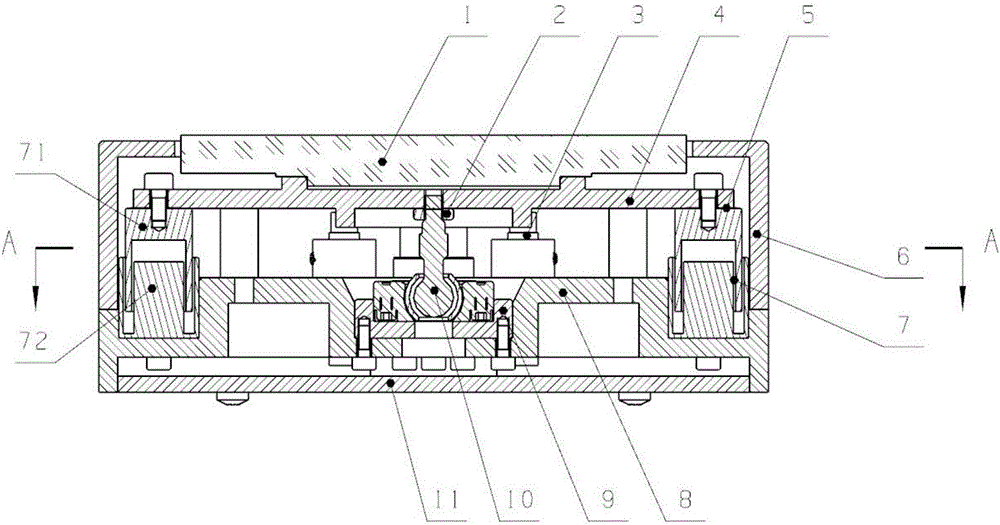

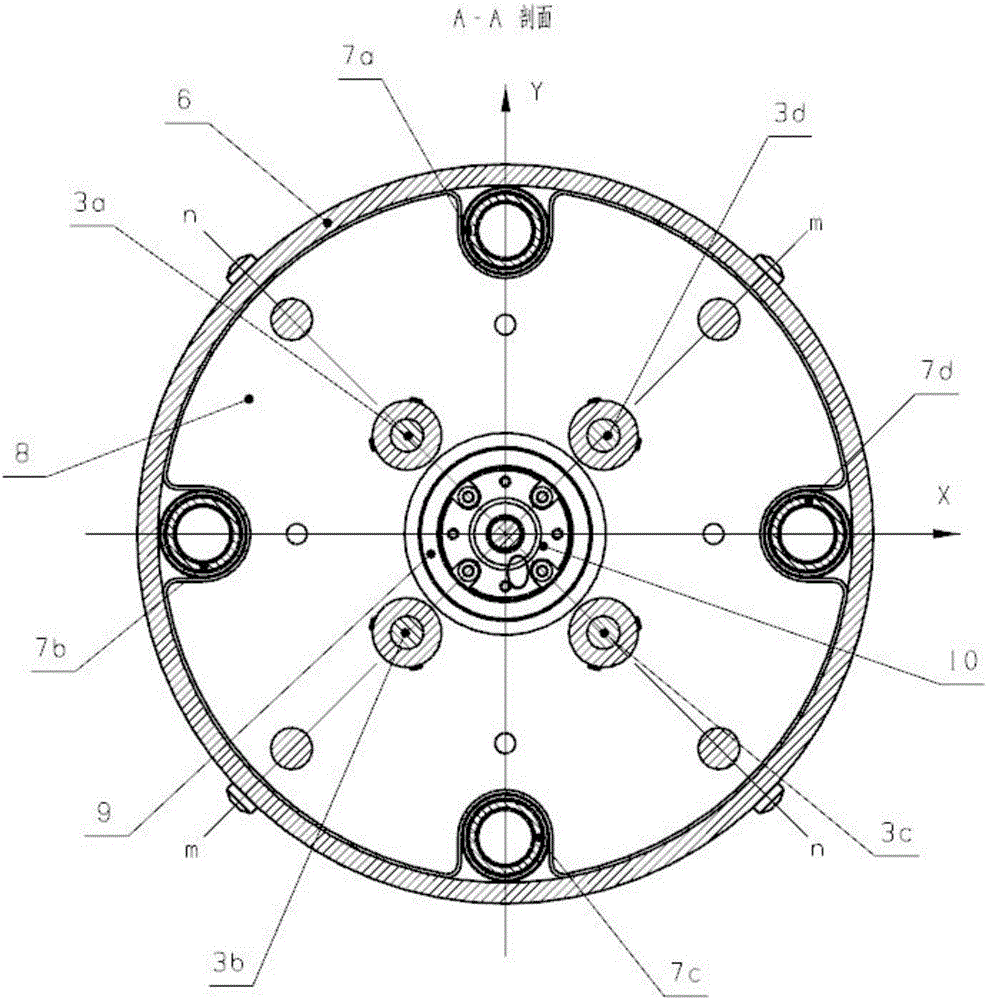

[0019] Specific embodiments 1. Universal large-diameter rigid load-bearing fast mirror, including a plane mirror 1, a round nut 2, an eddy current displacement sensor 3, a mirror seat 4, a flexible ring 5, an installation cover 6, and a linear voice coil motor 7. Base 8, bearing adapter seat 9, universal ball bearing 10 and bottom plate 11.

[0020] The plane reflector 1 is bonded together with the reflector base 4 by optical epoxy glue. The center of the reflector base 4 is connected with the universal ball bearing 10 through threads, and the round nut 2 is used for anti-loosening; the surroundings of the reflector base 4 are connected with the moving coil 71 of the voice coil motor 7 and the flexible ring 5 through evenly distributed lugs . The flexible ring 5 is fixed on the four flexible ring mounting posts 81 of the base 8 through four mounting holes therein.

[0021] The universal ball bearing 10 is installed on the center point of the base 8 through the bearing adapte...

specific Embodiment approach 2

[0026] Specific embodiment two, combine Figure 1 to Figure 4 Describe this implementation mode, this implementation mode is a specific example of the general large-diameter rigid load-bearing fast mirror described in the first specific implementation mode:

[0027] Including: plane mirror 1, round nut 2, first eddy current displacement sensor 3a, second eddy current displacement sensor 3b, third eddy current displacement sensor 3c, fourth eddy current displacement sensor 3d, mirror seat 4, flexible ring 5. Install the upper cover 6, the first linear voice coil motor 7a, the second linear voice coil motor 7b, the third linear voice coil motor 7c, the fourth linear voice coil motor 7d, the base 8, the bearing rotor Seat 9, universal ball bearing 10, base plate 11. The linear voice coil motor 7 is composed of a moving coil 71 and a fixed magnet 72;

[0028] The base 8 includes a flexible ring installation column 81 , a voice coil motor installation hole 82 , a sensor installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com