Environmental chamber for multi-parameter composite test

A composite test and environmental chamber technology, which is applied in the direction of impact test, machine/structural component test, space navigation condition simulation device, etc., can solve the problems of inability to fully simulate the working environment of the device, poor test effect and low precision, and achieve The effect of stable air pressure, uniform temperature and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

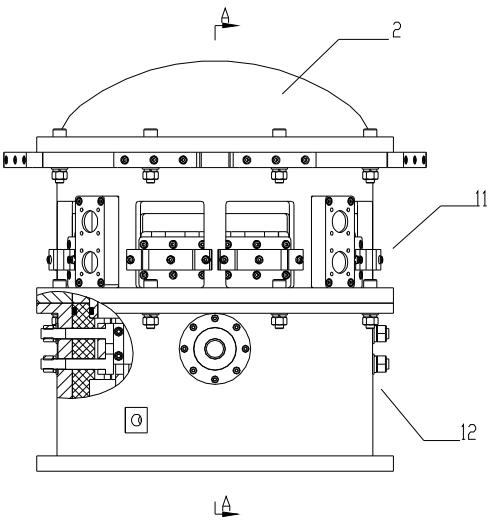

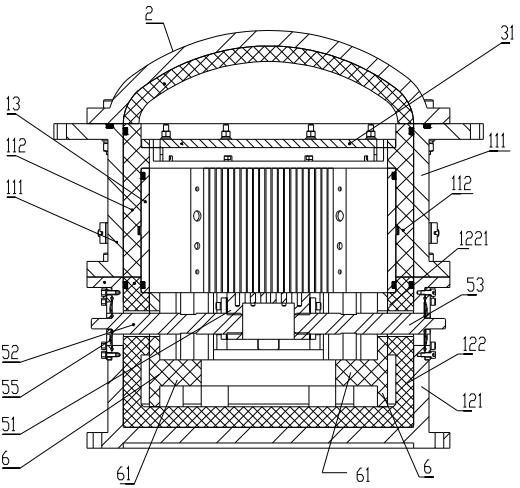

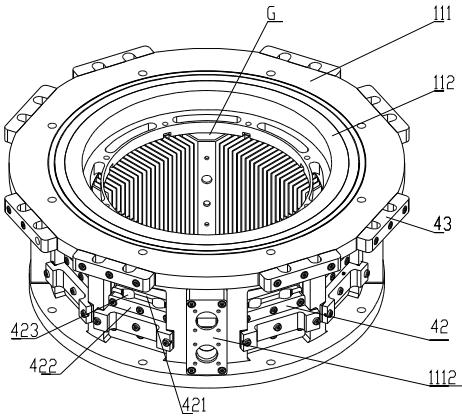

[0042] With reference to accompanying drawing, further illustrate the present invention:

[0043]An environmental chamber for multi-parameter composite tests, including a closed box body, the box body is sealed with the box cover 2, and the box body and the box cover 2 are made of metal to ensure the rigidity of the box body. The outer layer and the insulation layer made of non-metal to maintain the internal temperature of the composite cavity, the inner cavity of the box body forms an environmental composite cavity independent of the outside world;

[0044] The interior of the composite chamber is arranged in turn from top to bottom: a noise generating mechanism 3 fixed on the upper part of the composite chamber and a temperature control mechanism 4 on the wall of the composite chamber, which are located inside the composite chamber and linked with external vibration sources The vibration generating mechanism 5 is connected with the air pump to introduce gas into the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com