Desulfurization wastewater concentration reduction treating system and method based on nonsoftening and directional driving electrodialysis technology

A desulfurization wastewater and treatment system technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the difficulty of large-scale popularization and application of desulfurization wastewater concentration methods, the large amount of solid waste, Solve problems such as cumbersome and complicated steps to achieve the effects of saving softening agents, maintaining salt balance, and reducing waste generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

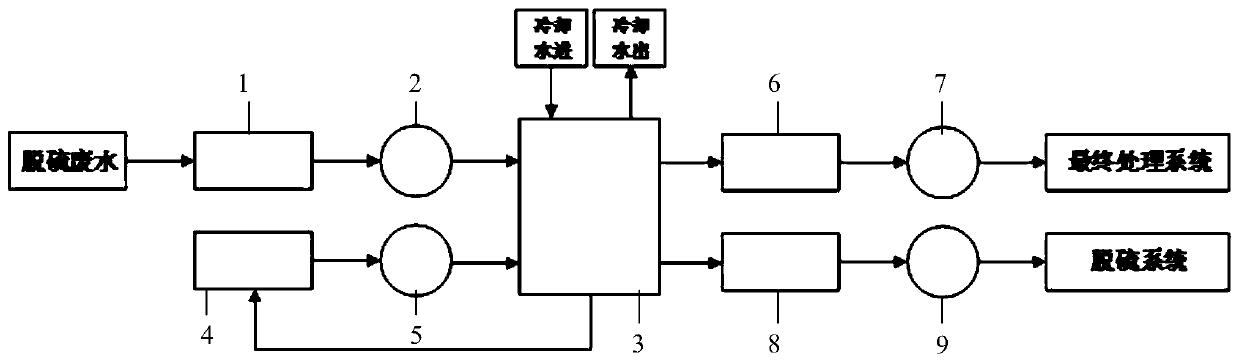

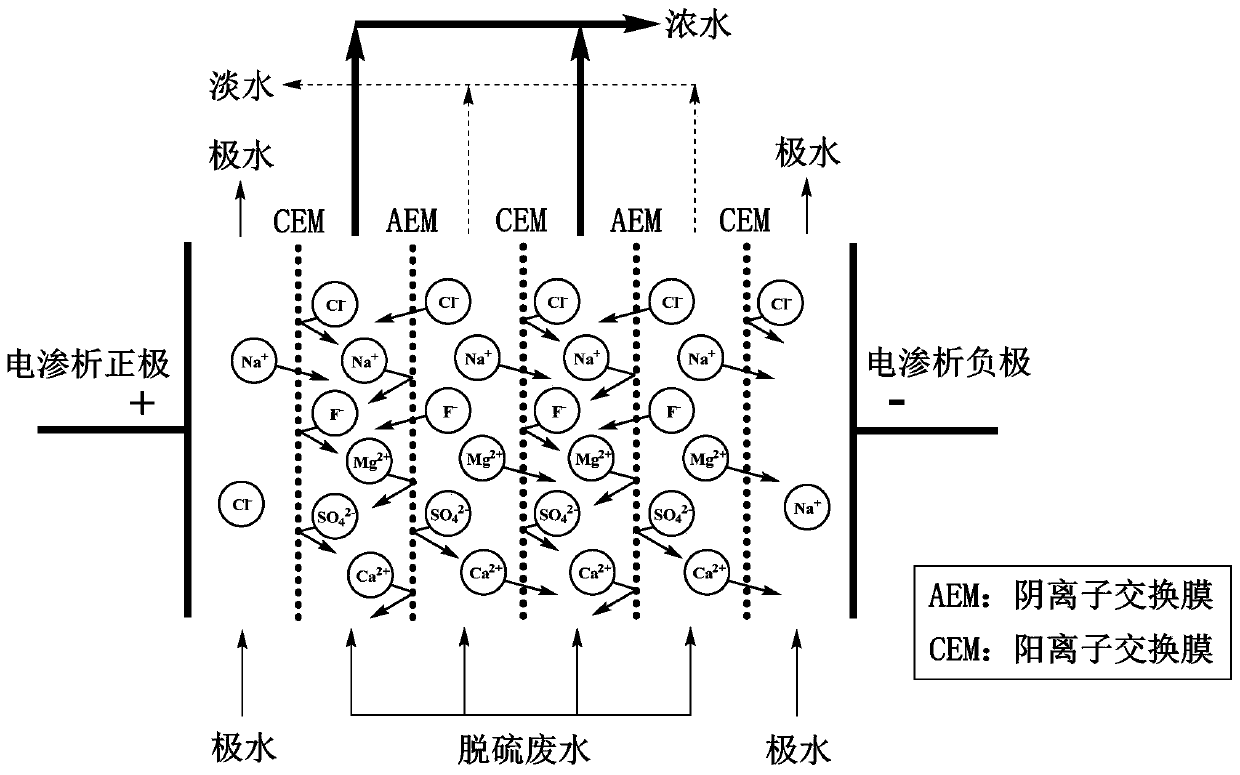

[0032] The desulfurization wastewater concentration and reduction treatment system based on non-softening and directional-driven electrodialysis technology includes wastewater raw water tank 1, wastewater raw water pump 2, directional-driven electrodialysis device 3, pole water tank 4, pole water pump 5, and concentrated waste water tank 6 , waste water concentrated water pump 7, waste water fresh water tank 8 and waste water fresh water pump 9; desulfurization wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com