Waste slurry treatment system capable of continuously adjusting flocculation scheme in real time and implementation method thereof

A waste mud and treatment system technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of inefficient suction filtration, discontinuity, and unsatisfactory treatment and other problems, to achieve the effect of thorough reduction and enhanced concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

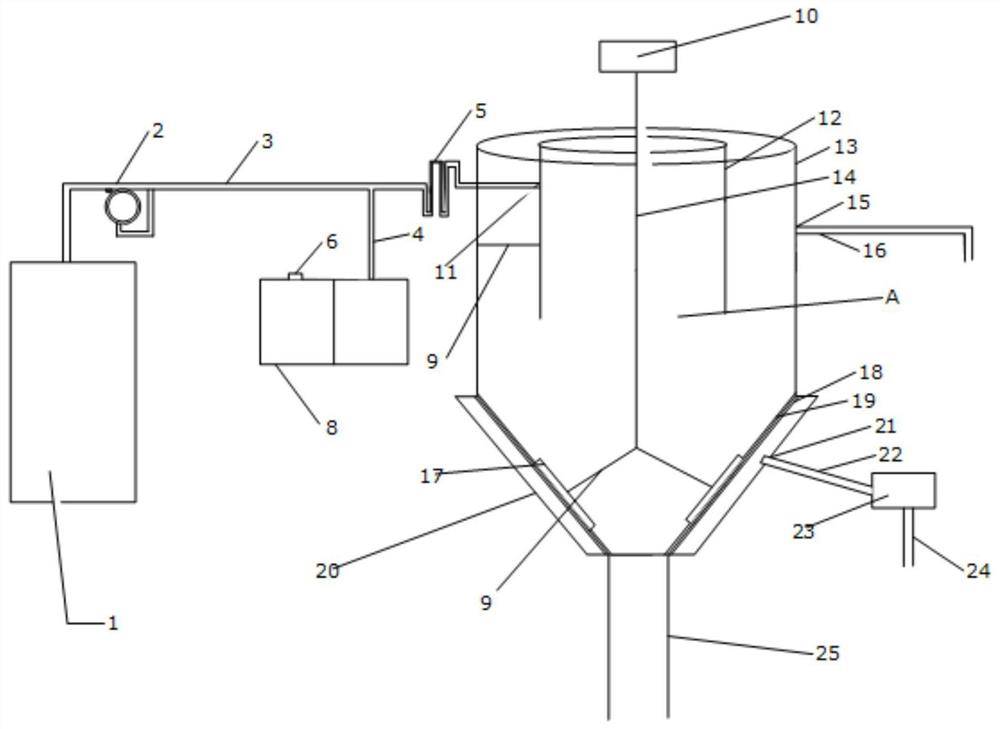

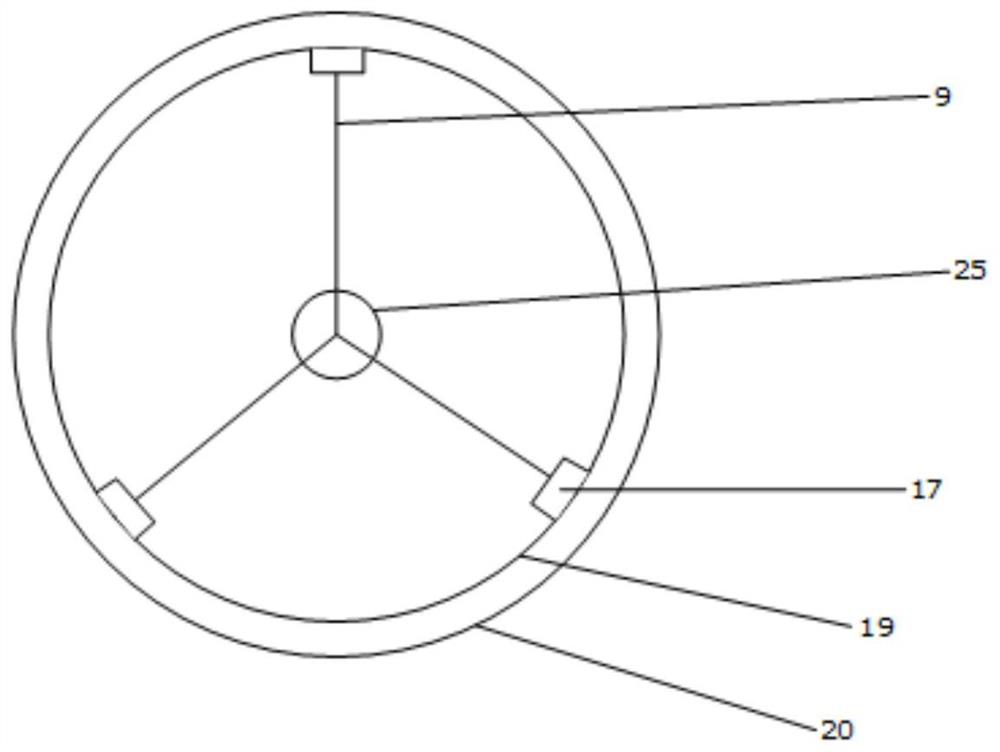

Embodiment 1

[0036] When the mud moisture content ω n ≥300%, according to formula C n =eC 3 ω n / ω 0 , to obtain the corresponding flocculant concentration at this time, e is a constant, which can be obtained through the flocculation test of known gradient mud moisture content, the value of e is 0.3 according to the small test test, C 3 is the corresponding flocculant concentration when the water content of the mud is 300%, and C is measured according to the small test 3 The value of 2‰, a certain known water content of mud ω 0 The value of is 200%; assuming that the mud water content at this time is 400%, the flocculant C n The concentration is C n =0.3×0.002×4÷2, C n =1.2‰. After the flocculant concentration is configured, it is sent to the mud delivery pipeline 3 . The flocculant delivery pipeline 4 is an anti-corrosion plastic pipeline with a diameter of 5 cm, and the pipeline at the mud delivery inlet of the material tank A is an S-shaped pipeline 5, where the mud and the flo...

Embodiment 2

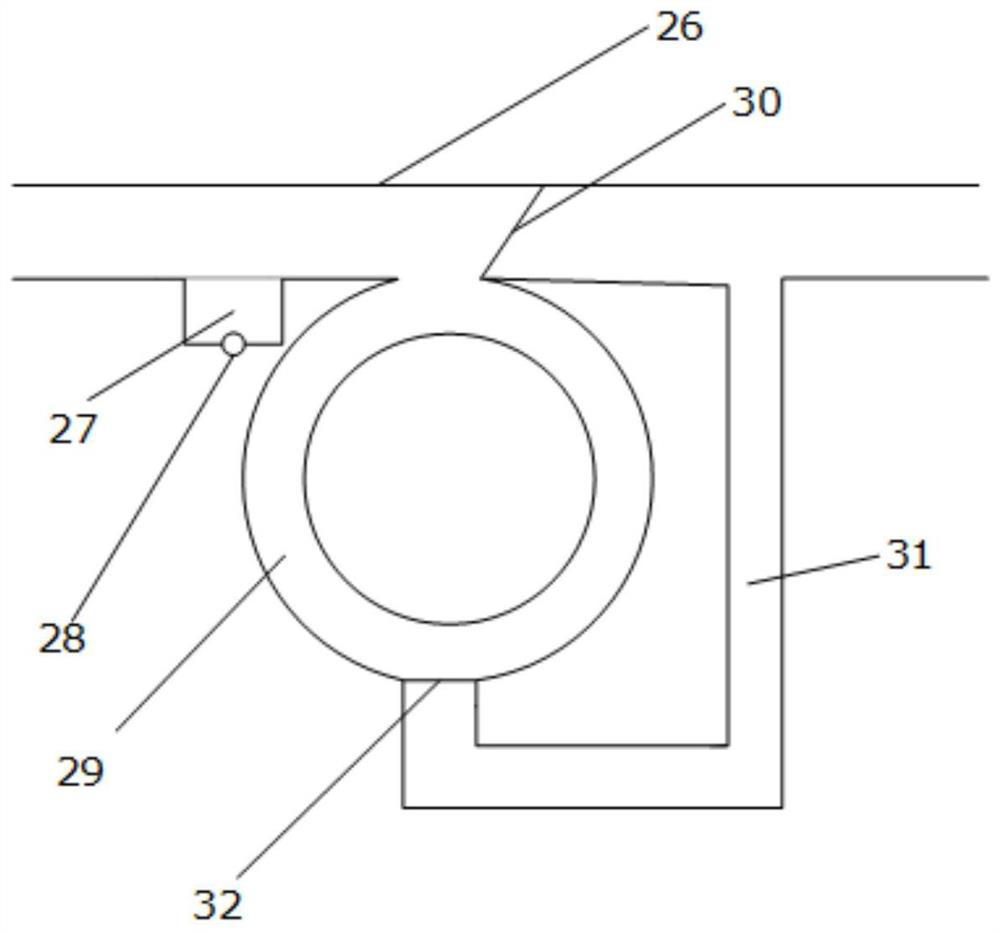

[0039] When the mud moisture content ω n When ≤300%, the signal receiving processor 6 will transport the mud to the annular pipe 29, and at this time the switch 32 is closed, and the mud will be uniformly diluted in this pipe until the light transmittance is consistent with the light transmittance when the water content of the mud is 300%. , according to the small test, the transmittance T of mud moisture content 300% 1 =60%, assuming that the water content of the mud at this time is 200%, the corresponding light transmittance is T n , the transmittance of the diluted mud T 1 =T n =60%, now open switch 32, then mud enters mud delivery pipeline 3 by L shape mud delivery pipeline 31, C 3 The flocculant of =2‰ is delivered to the mud delivery pipeline 3 and mixed with the mud. The flocculant delivery pipeline 4 is an anti-corrosion plastic pipeline with a diameter of 5 cm, and the pipeline at the mud delivery inlet of the material tank A is an S-shaped pipeline 5, where the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com