Zero discharge method of salt-containing wastewater

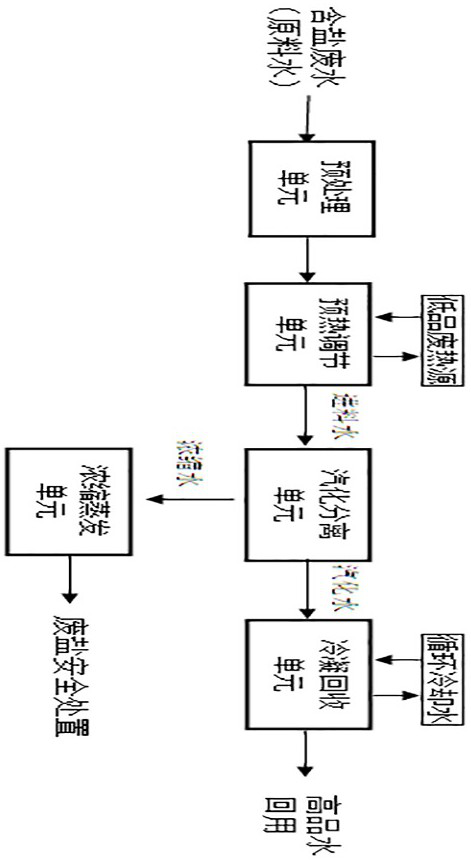

A salty wastewater, zero-discharge technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low recycling rate, long process route and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material water source: Salt production wastewater from a certain enterprise, the amount of wastewater produced is 5m 3 / d. pH value 5.5, CODcr240mg / L, SS 80mg / L, Ca 2+ 1200 mg / L, Mg 2+ 1350mg / L, TDS230000mg / L.

[0028] Pretreatment: After the raw material water is treated through physical, chemical and oxidation processes, the SS is reduced to below 20 mg / L, and the CODcr is reduced to below 50 mg / L.

[0029] Preheating adjustment: the feed water in step (1) is stirred and mixed by air; it is preheated to 58-62°C by heat exchange with the waste flue gas at 80°C in the plant through a tubular heat exchanger.

[0030] Vaporization separation: the feed water in step (2) is heated by heat exchange with the waste flue gas at 80°C in the plant through a tubular heat exchanger, and the temperature is controlled at 65°C; then pervaporation is carried out through the SY-PVLCS-II membrane module Separation of vaporized water to achieve concentration reduction of feed wate...

Embodiment 2

[0036] Source of raw water: high-concentration saline wastewater produced by an enterprise, the amount of wastewater produced is 30m 3 / week. pH value 7.8, CODcr2100mg / L, turbidity 2NUT, TDS210000mg / L.

[0037] Raw material water pretreatment: After physical, chemical and oxidation treatment, CODcr is reduced to below 200 mg / L.

[0038] Preheating adjustment: the feed water in step (1) is preheated to 60-65°C by heat exchange with the 85°C waste hot water generated by the heat exchange and condensation of steam in the plant through a tubular heat exchanger; it is stirred and mixed by a mixer.

[0039] Vaporization separation: the raw material water in step (2) is heated by a metal heater, the temperature is controlled at 68°C, and then the vaporized water is separated by pervaporation through the SY-PVLCS-I type membrane module, so as to realize the concentration and weight loss of the feed water.

[0040] Condensation recovery: the vaporized water separated in step (3) is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com