High-temperature condensation water fine treatment system and high-temperature condensation water fine treatment method

A technology for high-temperature condensate and fine treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of rough treatment system, cumbersome process, and the introduction of a large amount of oxygen , to achieve the effect of saving equipment investment cost, wide range of use, and simple processing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

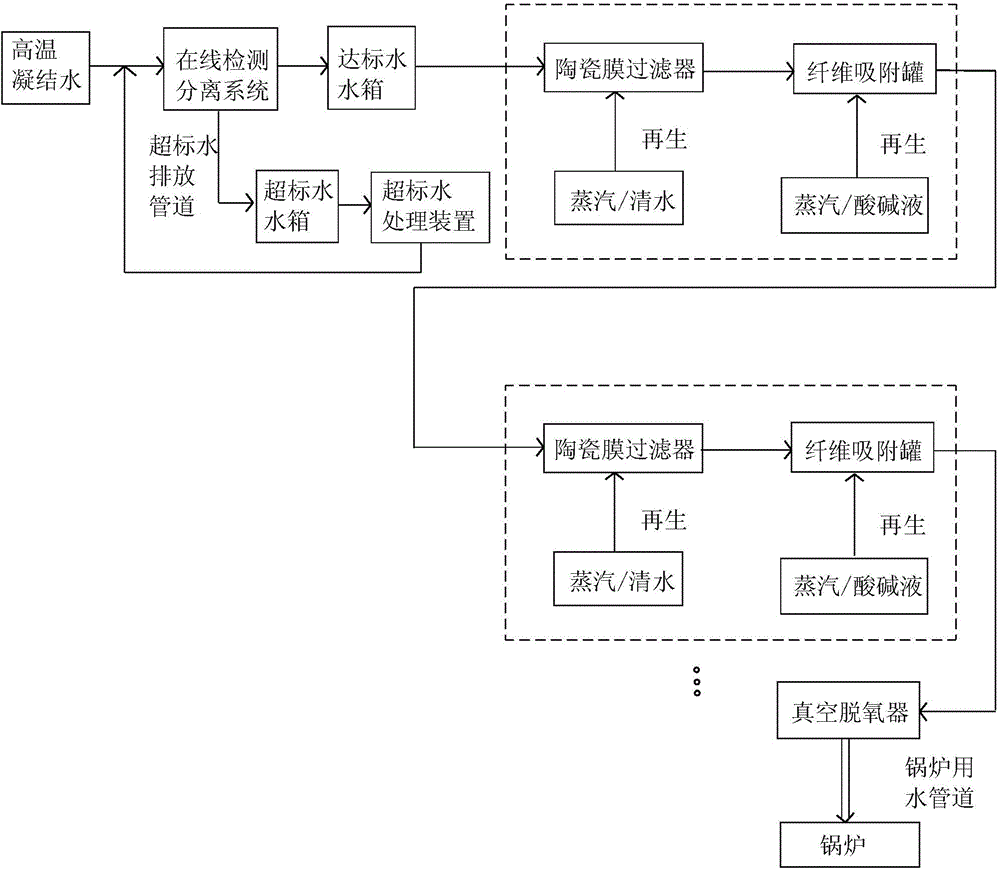

[0029] A method for performing high-temperature condensate polishing using the above system, the method includes the following steps: the high-temperature condensate is detected by an on-line detection and separation system for indicators in the water containing condensate oil, sol-state SiO 2 , iron ion, copper ion content, one or more of the conductivity, the water that meets the treatment requirements will enter the standard water tank, the water that does not meet the treatment requirements will enter the over-standard water tank, and the water in the over-standard water tank will enter the over-standard water treatment device , the water that passes through the water treatment device that exceeds the standard enters the online detection and separation system again; the water in the water tank that reaches the standard is deoiled and desalted by the water polishing treatment device, and after desalination treatment, it enters the vacuum deaerator for degassing operation, and...

Embodiment 2

[0037] A method for performing high-temperature condensate polishing using the above system, the method includes the following steps: the high-temperature condensate is detected by an on-line detection and separation system for indicators in the water containing condensate oil, sol-state SiO 2 , iron ion, copper ion content, one or more of the conductivity, the water that meets the treatment requirements will enter the standard water tank, the water that does not meet the treatment requirements will enter the over-standard water tank, and the water in the over-standard water tank will enter the over-standard water treatment device , the water that passes through the water treatment device that exceeds the standard enters the online detection and separation system again; the water in the water tank that reaches the standard is deoiled and desalted by the water polishing treatment device, and after desalination treatment, it enters the vacuum deaerator for degassing operation, and...

Embodiment 3

[0045] A method for performing high-temperature condensate polishing using the above system, the method includes the following steps: the high-temperature condensate is detected by an on-line detection and separation system for indicators in the water containing condensate oil, sol-state SiO 2 , iron ion, copper ion content, one or more of the conductivity, the water that meets the treatment requirements will enter the standard water tank, the water that does not meet the treatment requirements will enter the over-standard water tank, and the water in the over-standard water tank will enter the over-standard water treatment device , the water that passes through the water treatment device that exceeds the standard enters the online detection and separation system again; the water in the water tank that reaches the standard is deoiled and desalted by the water polishing treatment device, and after desalination treatment, it enters the vacuum deaerator for degassing operation, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com