Rotary pulling type water tap

A faucet and pull-up technology, which is applied in the direction of lifting valves, valve details, engine components, etc., can solve problems such as inconvenient operation, easy slipping of rotating threads, and grinding of the cylindrical side of the valve core, etc., to achieve a stable lifting process , prolong the service life, and adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

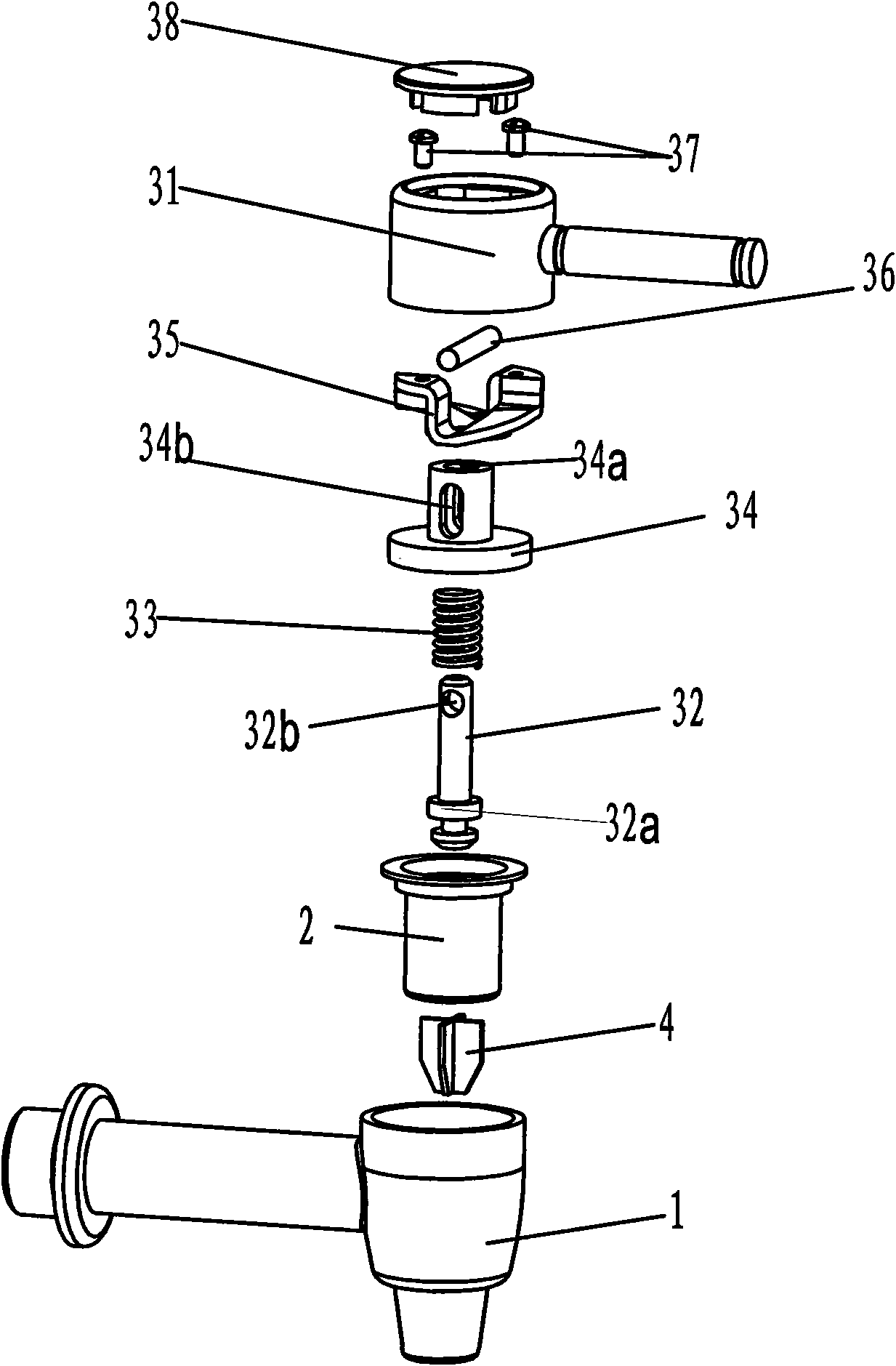

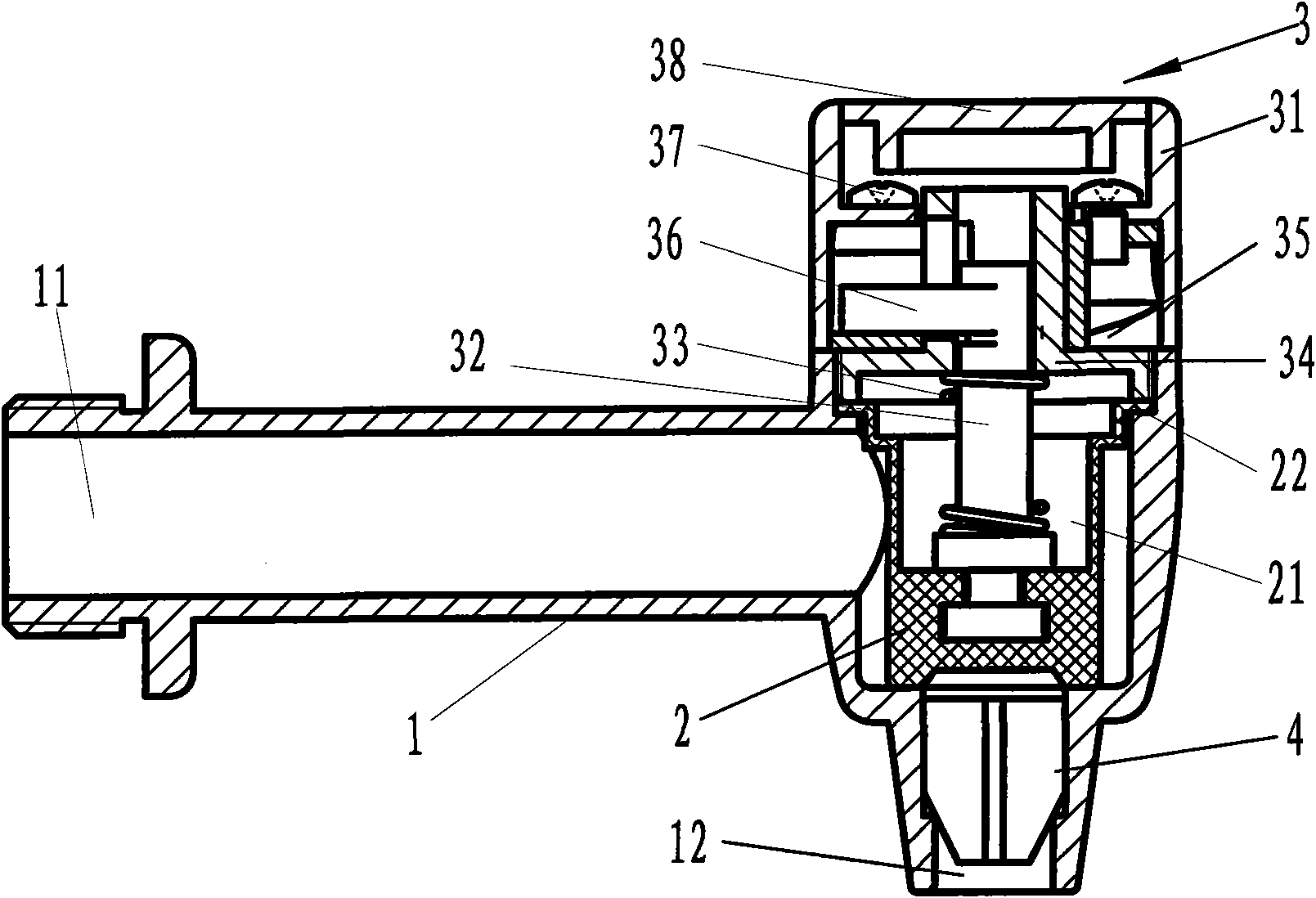

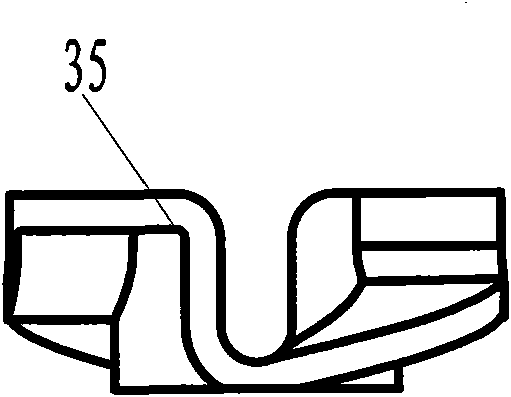

[0031] figure 1 , figure 2 , Figure 3a , 3b , Figure 3c , Figure 3d , Figure 3e , Figure 4 and Figure 5 Constitute the specific embodiment 1 of the present utility model.

[0032] see figure 1 and figure 2 , this embodiment includes a valve body 1, the valve body is provided with a water inlet 11 and a water outlet 12; a valve core 2 is arranged above the water outlet in the inner cavity of the valve body 1; a rotating lifting mechanism 3 is provided on the valve body 1, so The rotating lifting mechanism 3 is fixedly connected with the valve core 2, and the rotating lifting mechanism 3 drives the valve core 2 to rise or fall in the axial direction, so that the water inlet 11 and the water outlet 12 are connected or cut off. The cross section of the valve body 1 is "right-angled" shape, the left end of its transverse end is provided with a water inlet 11, and the bottom of its vertical end is provided with a water outlet 12; the valve core 2 is arranged in the...

specific Embodiment 2

[0039] The characteristics of this embodiment are: the cross section of the valve body 1 is "T" shape, the left end of the horizontal end of the valve body 1 is provided with a water inlet 11, and the bottom of the vertical end of the valve body 1 is provided with a water outlet 12; 2 is arranged in the inner cavity of the vertical end of the valve body and is located above the water outlet 12. A deflector is provided at the water outlet of the valve body. The spool (2) is made of a silicone spool or a ceramic spool, and is a silicone spool or a ceramic spool. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com