Circulation method and device of bridge type sintering machine

A technology of sintering device and sintering machine, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., and can solve the problems of high requirements for workshops, low efficiency, and high equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

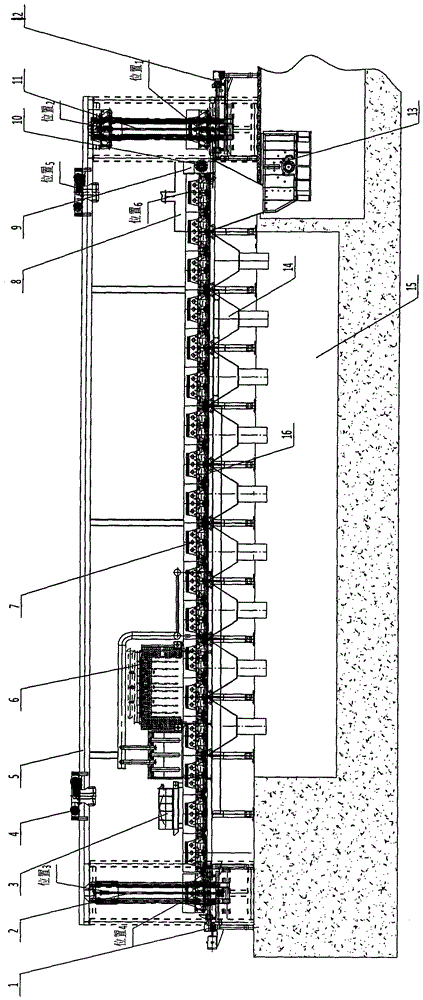

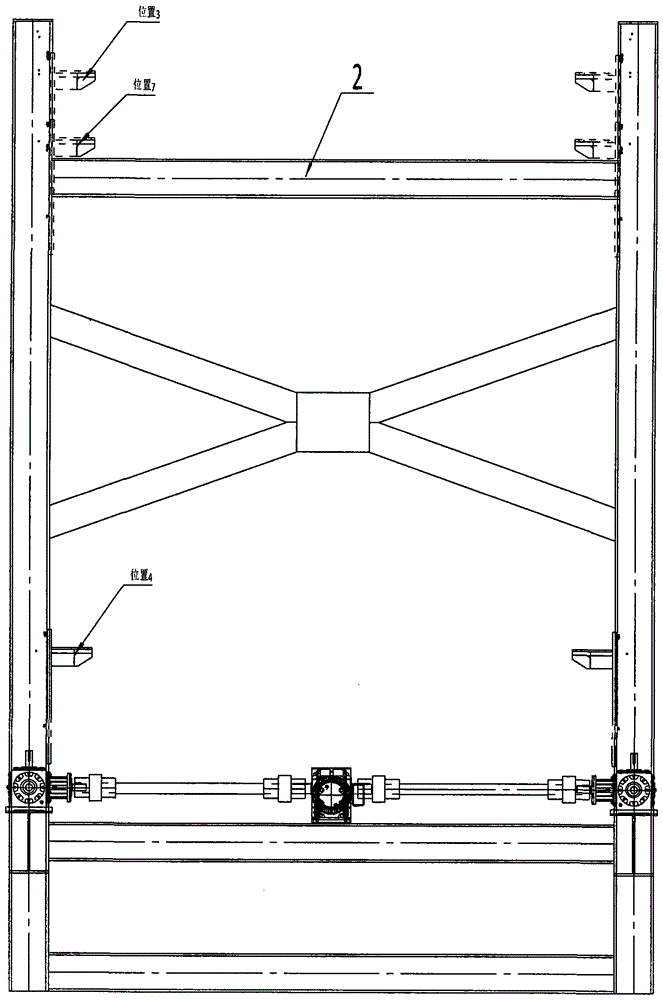

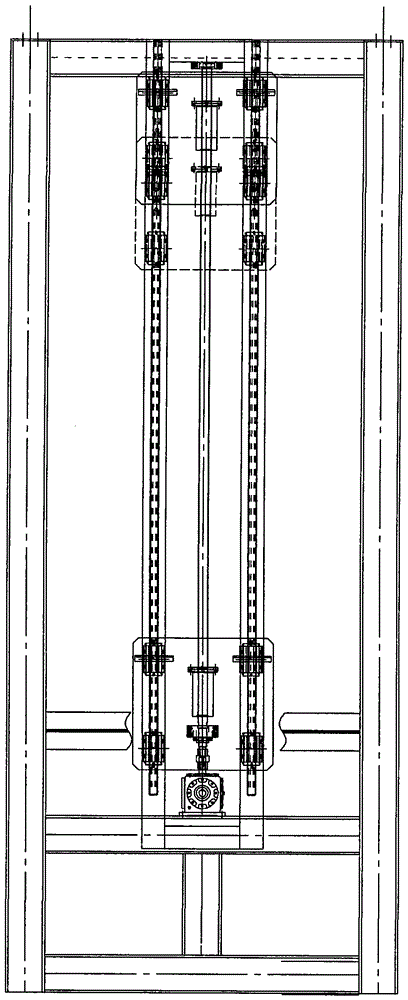

[0046] Such as figure 1 As shown, the bridge-type sintering line furnace cars are arranged in a straight line, and each furnace car has an induced draft chamber 14 ( figure 1 It is shown in the sintering line that there are 9 sintering induced air chambers), the induced air chamber 14 directly communicates with the dust collecting chamber 15 through pipes, and the furnace car unloader 12, the unloading baffle 9 and the second A furnace car lift 11, a furnace car propeller 1 and a second furnace car lift 2 are arranged at the starting end, and a furnace car moving power trolley track 5 and a power trolley 4 are arranged above the furnace car. The furnace car propeller 1 is a lead screw transmission mechanism, and the lead screw nut is advanced and retreated through the rotation of the lead screw. A propulsion plate is installed on the lead screw nut, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com