Solid-containing wastewater separation device and solid-containing wastewater separation control method

A control method and wastewater technology, which are applied in separation methods, centrifugal separation water/sewage treatment, water treatment parameter control, etc., can solve the problems of pressure energy waste, high civil construction cost, long time, etc. Achieving, reducing processing costs and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

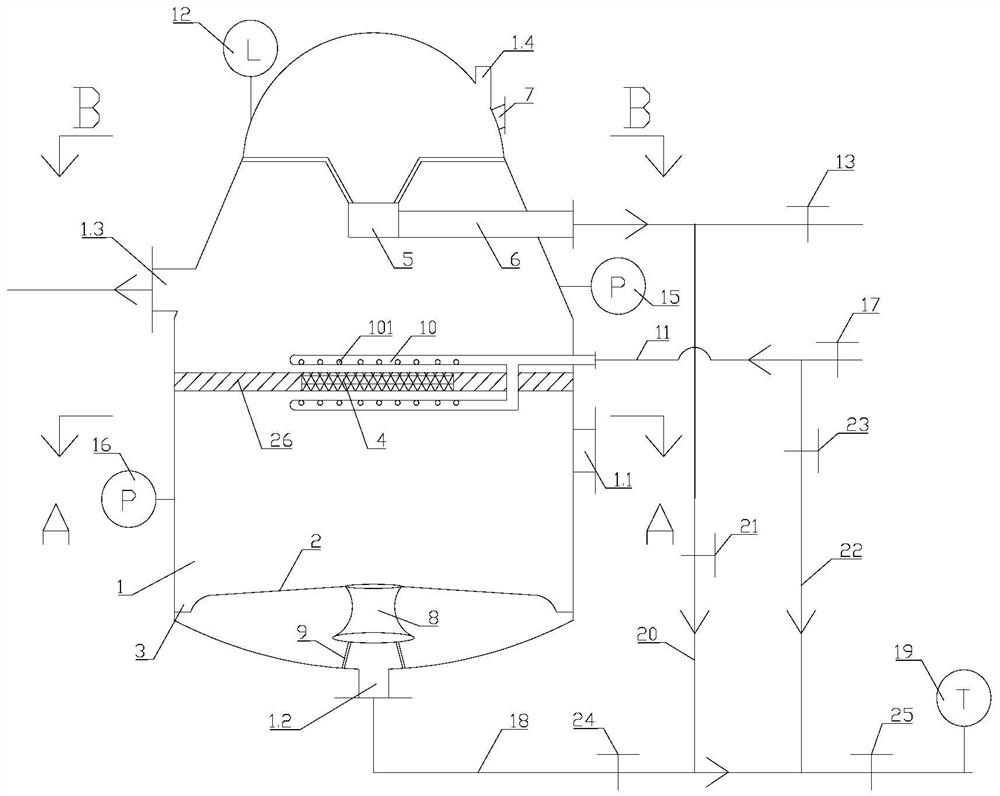

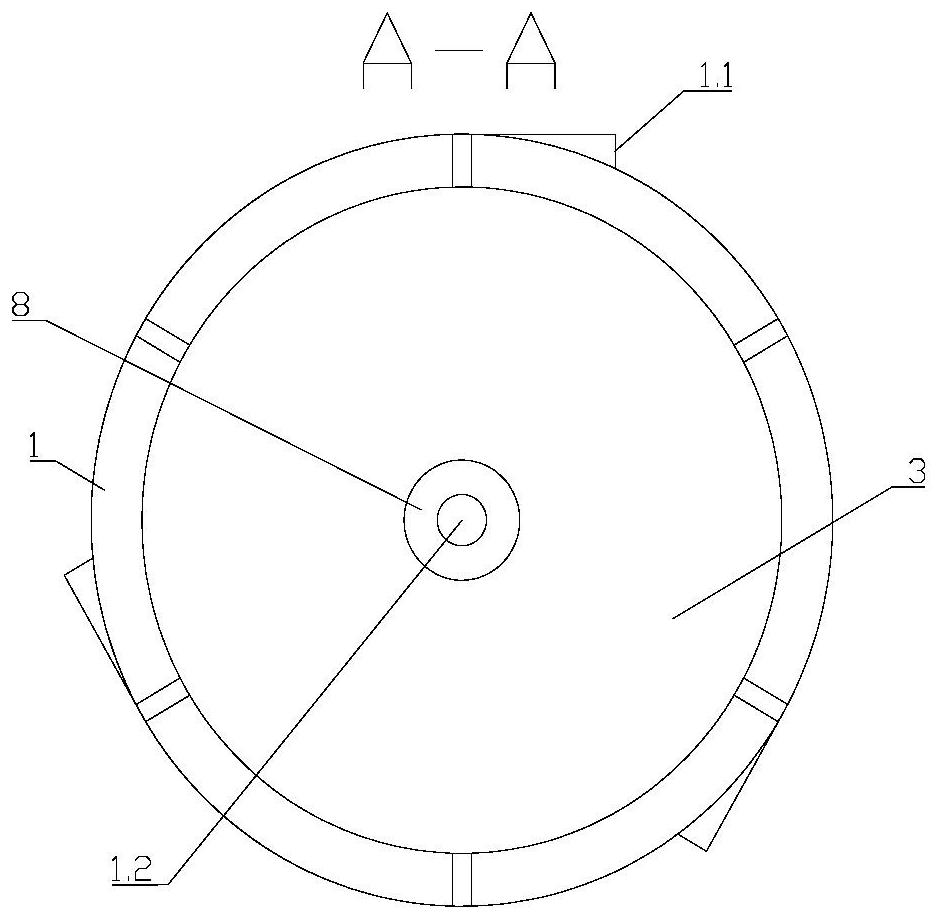

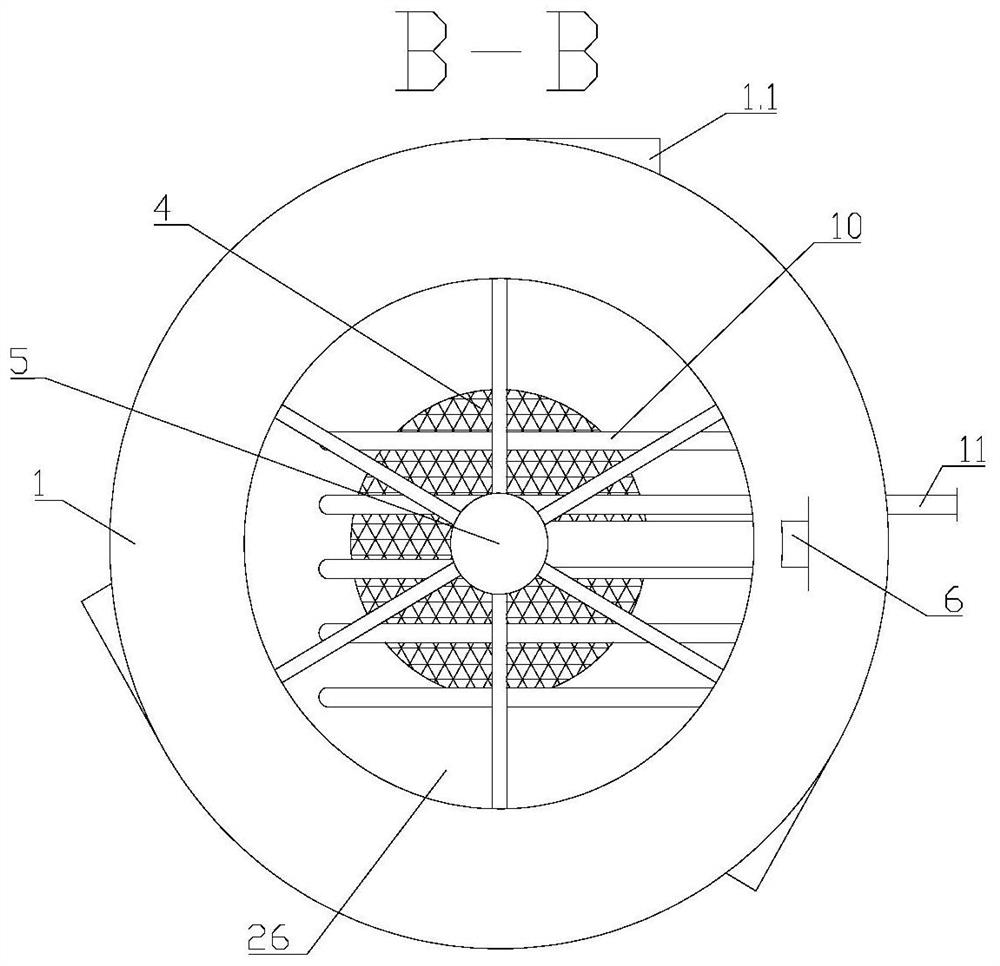

[0034] Embodiment 1: as Figure 1-4As shown, a device for separating solid-containing wastewater includes a housing 1; three sewage inlets 1.1 are arranged on the side wall of the housing 1, and the sewage inlets 1.1 are arranged along the tangential direction of the housing 1; below the sewage inlet 1.1 A separation plate 2 is fixed horizontally in the housing 1; an annular gap 3 is formed between the edge of the separation plate 2 and the inner wall of the housing 1; a mud discharge port 1.2 is opened on the housing 1 below the separation plate 2; 1.1 A filter plate 4 is horizontally fixed in the housing 1 above the filter plate 4; a water outlet 1.3 is opened on the side wall of the housing 1 above the filter plate 4, and the housing 1 above the water outlet 1.3 is conical, which can float on the water surface The dust gathers on the top to facilitate the stratification of the lower wastewater liquid and the upper layer of floating impurities, forming thicker floating impur...

Embodiment 2

[0041] Embodiment 2: Utilize the device of embodiment 1 to carry out the control method of separating solid-containing waste water, it may further comprise the steps:

[0042] (1) Separation for the first time: solid waste water enters the shell 1 from the sewage inlet 1.1 along the tangential direction of the shell 1 to form a vortex; the sludge with large particle size flows from the annular gap 3 to the bottom of the shell 1 under centrifugal action, Discharge from the mud discharge pipe 18;

[0043] (2) Separation for the second time: the waste water after step 1 is separated for the first time is filtered through filter plate 4 to remove impurities;

[0044] (3) The third separation: in step 2, the fine ash and light oil impurities that cannot be filtered by the filter plate 4 float on the surface of the waste water above the housing 1, are collected by the collection tank 5, and are discharged from the slag discharge pipe 6, and the collection tank The waste water betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com