Patents

Literature

51results about How to "Perfect combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

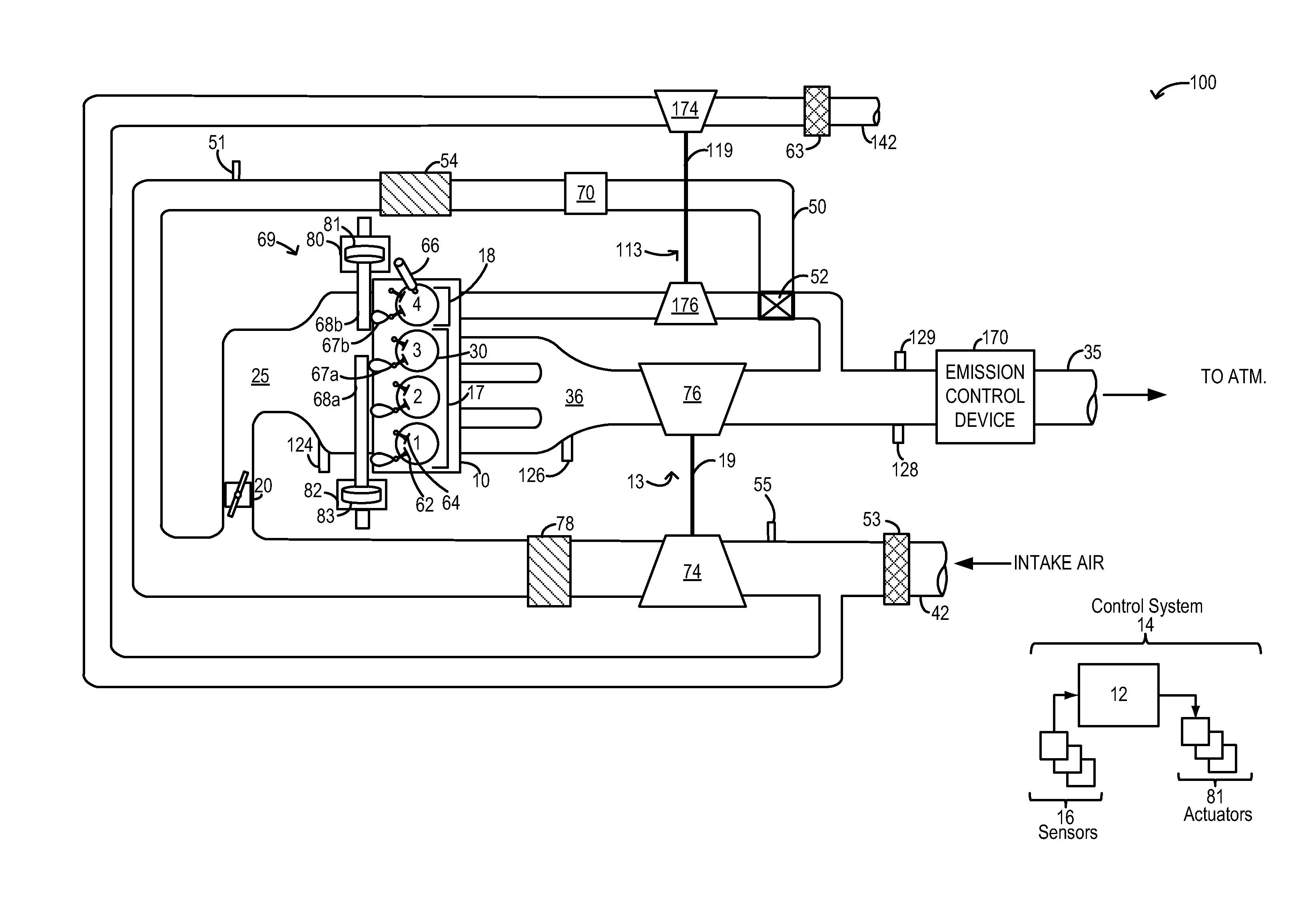

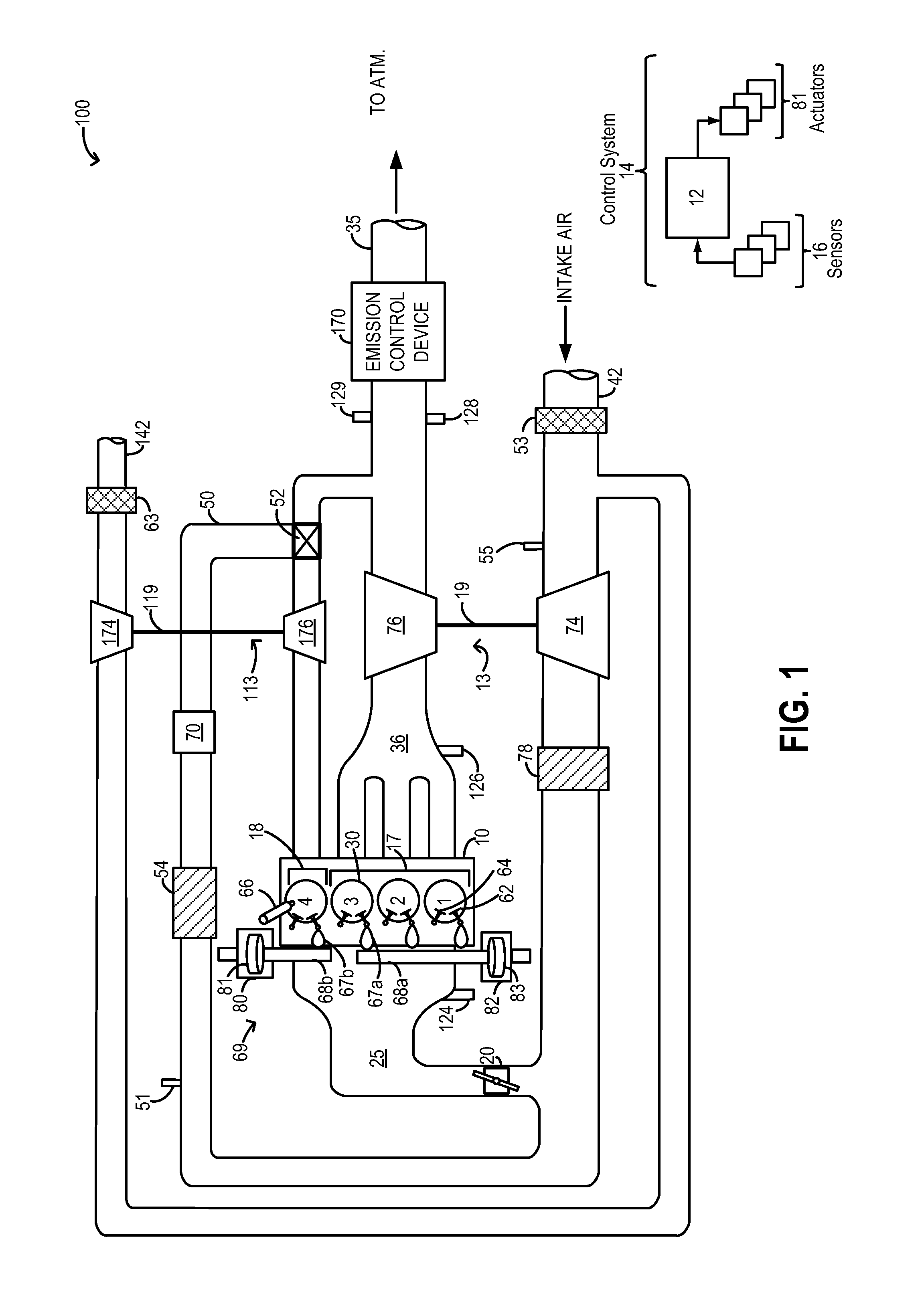

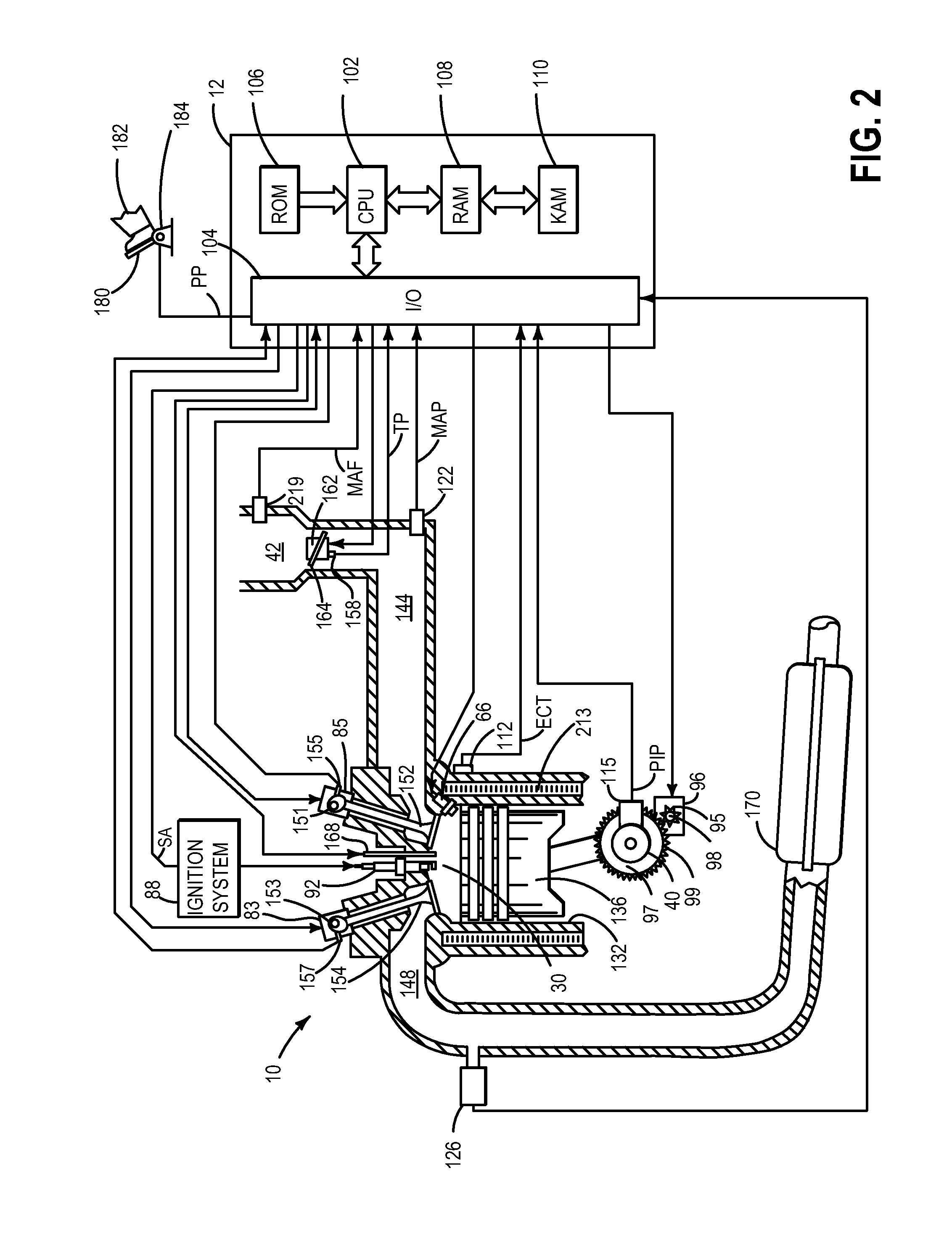

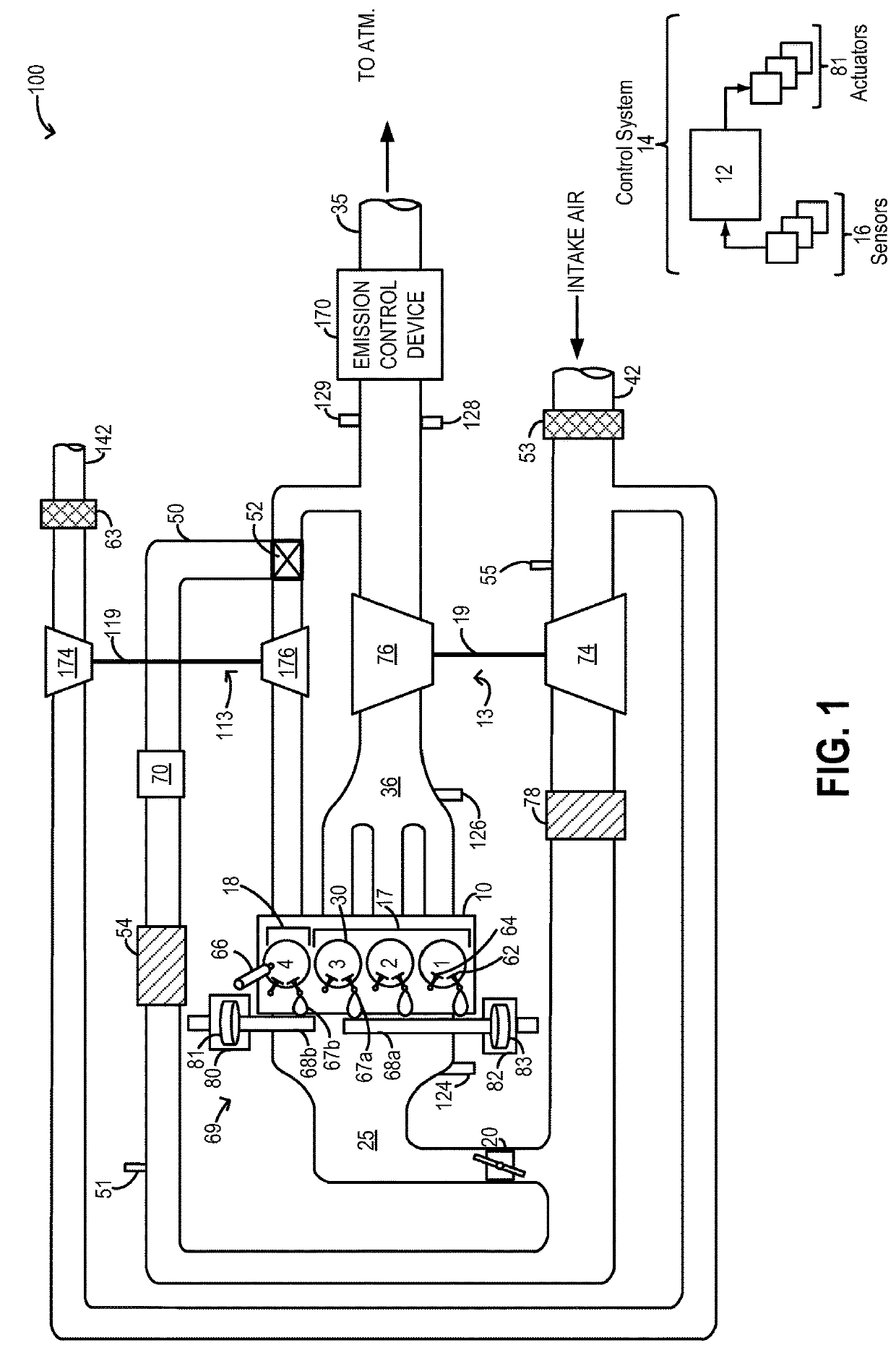

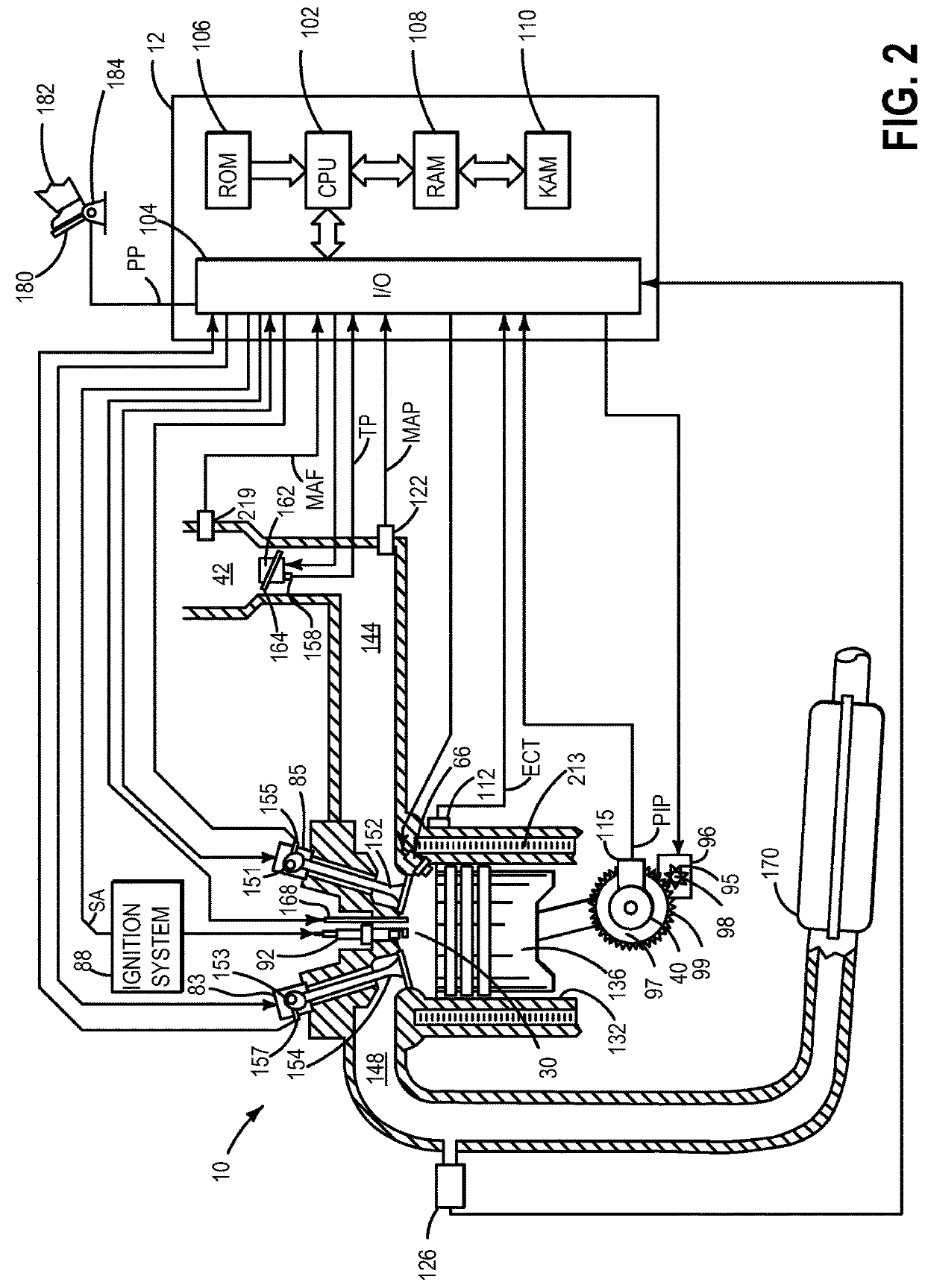

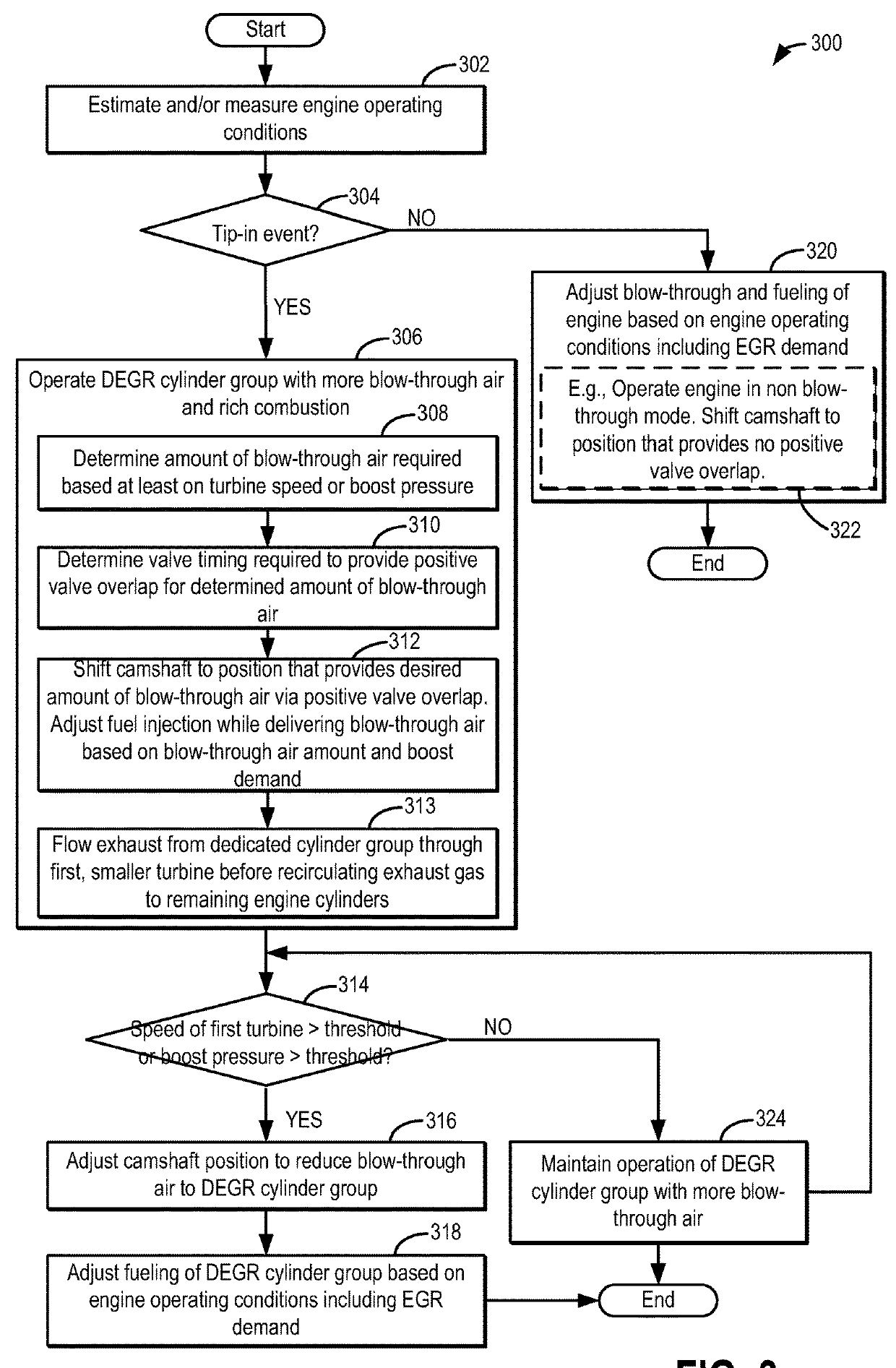

Systems and methods for boost control

InactiveUS20150361927A1Reduce NOx emissionImprove fuel economyElectrical controlInternal combustion piston enginesAutomotive engineeringAir–fuel ratio

Methods and systems are provided for reducing turbo lag in an engine system configured with a cylinder dedicated for exhaust gas recirculation and distinct turbines coupled to the dedicated EGR cylinder and remaining engine cylinders. An air-fuel ratio of combustion in the dedicated cylinder is adjusted responsive to a tip-in event by providing blow-through air and additional fuel based on the amount of heat required to spin up a turbine coupled to the dedicated cylinder and provide the requested boost pressure. The approach enables turbo lag to be reduced while providing high EGR at high boost conditions.

Owner:FORD GLOBAL TECH LLC

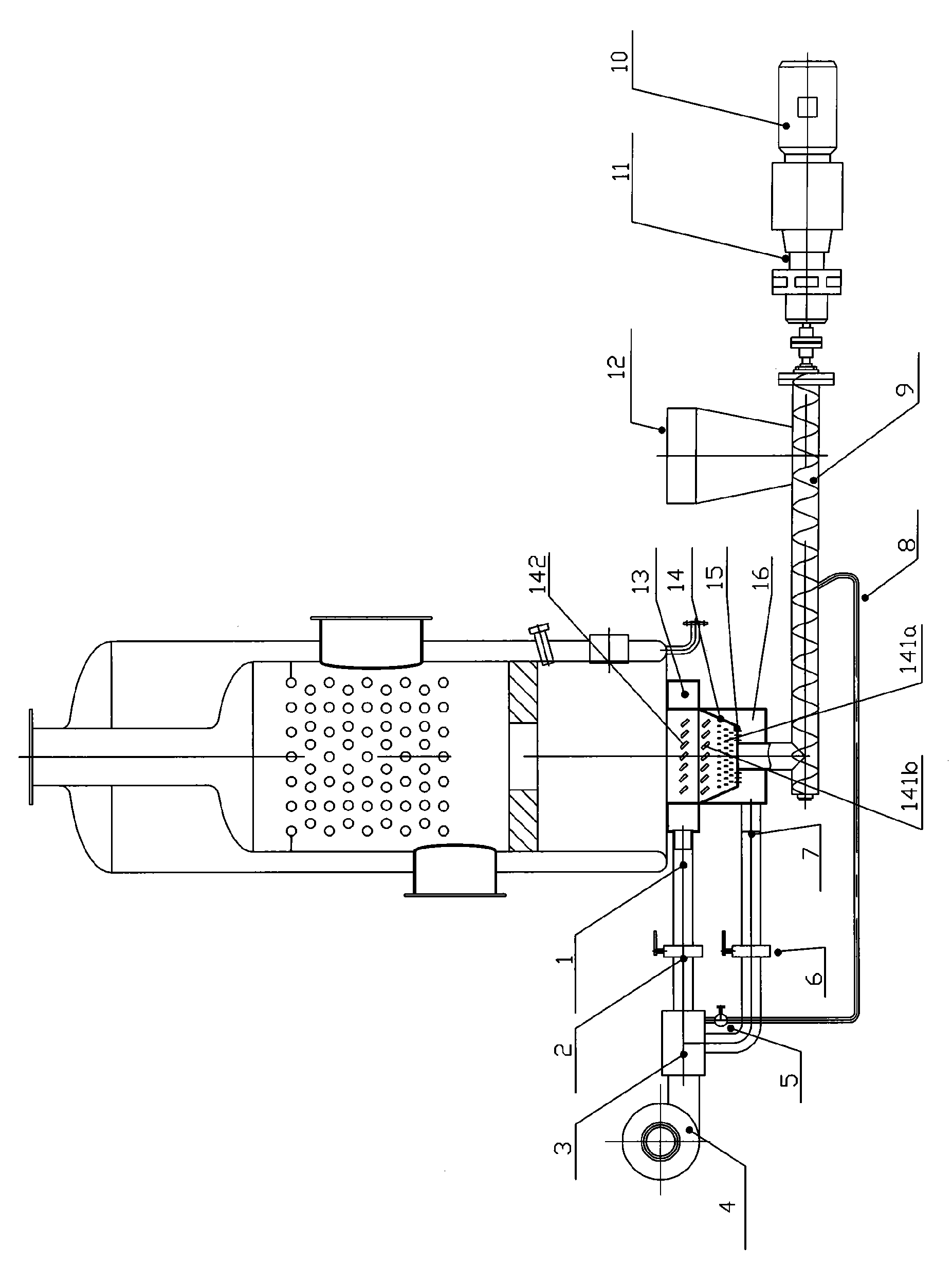

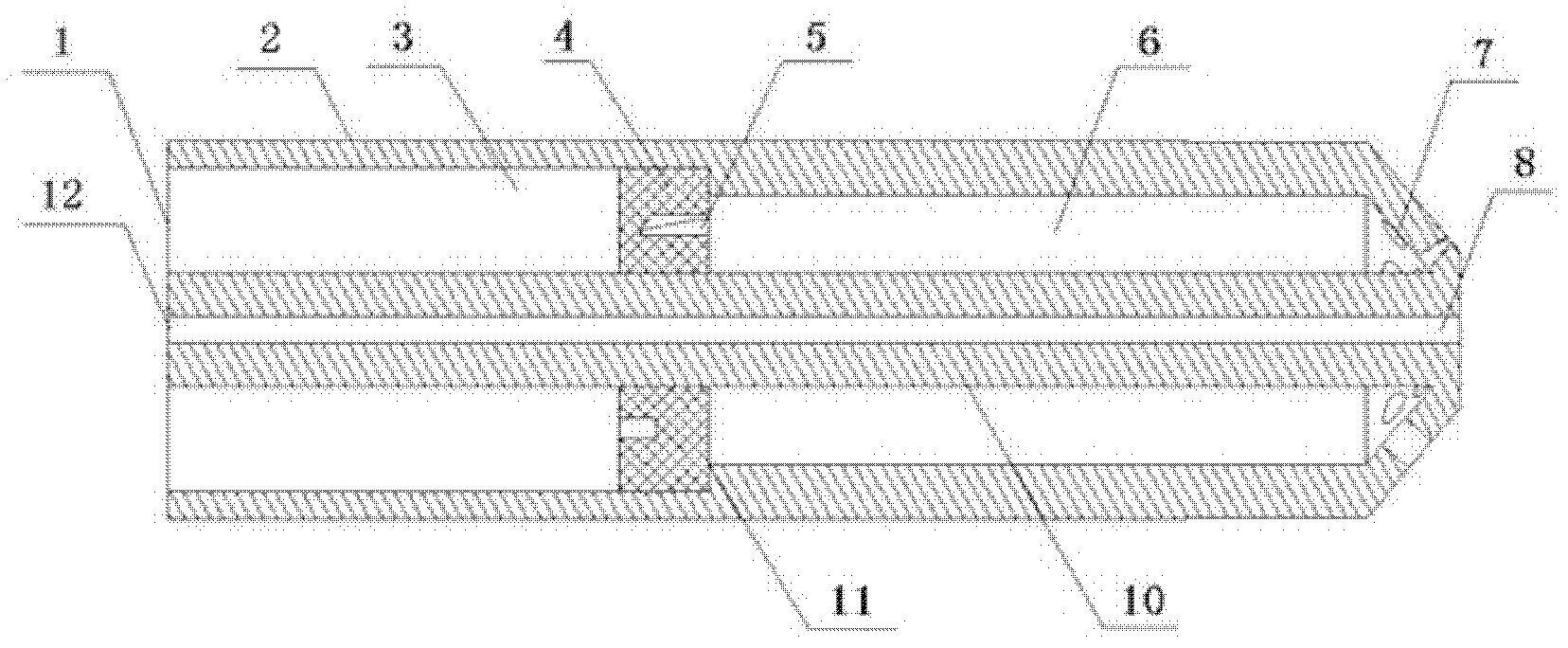

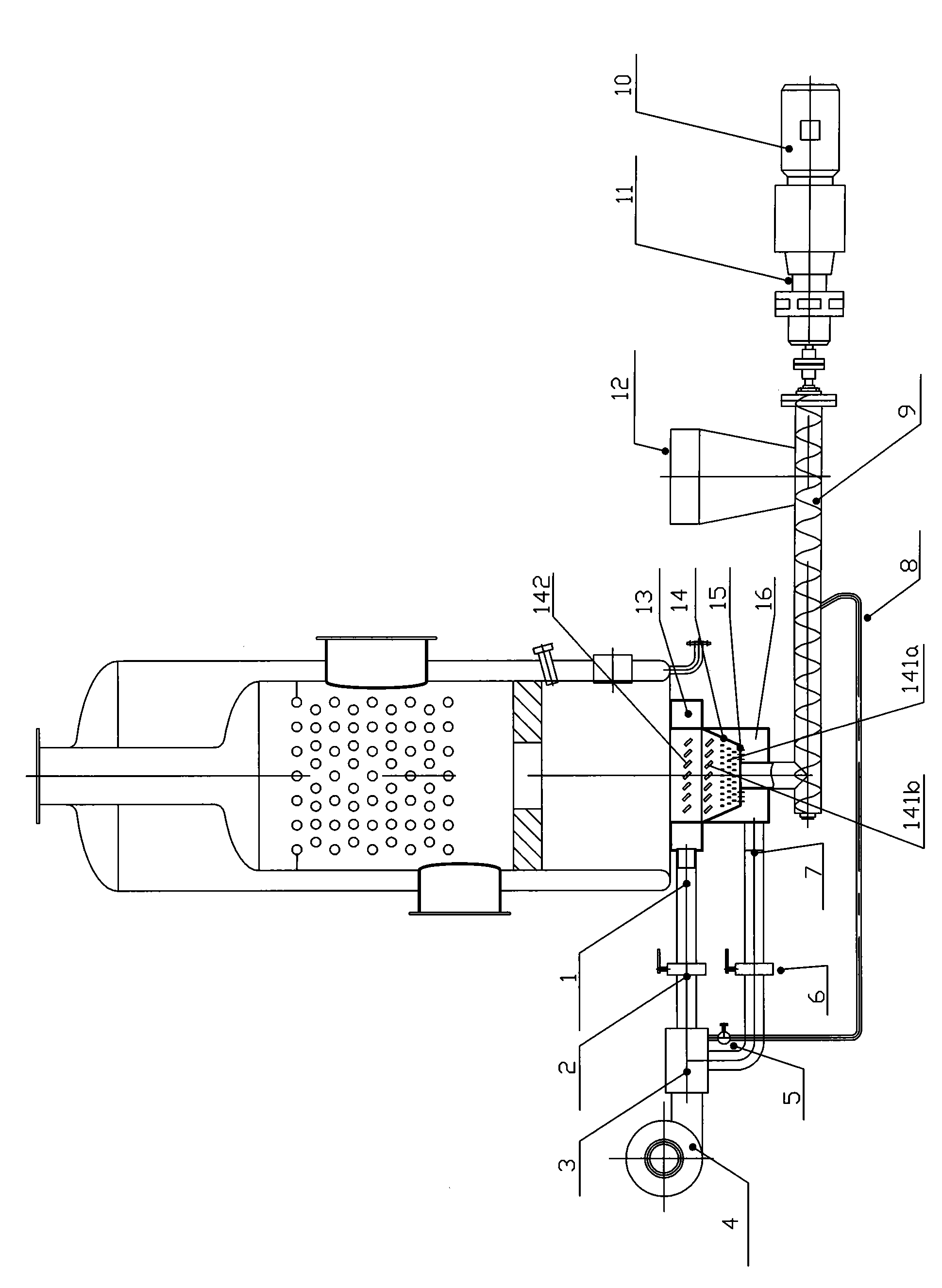

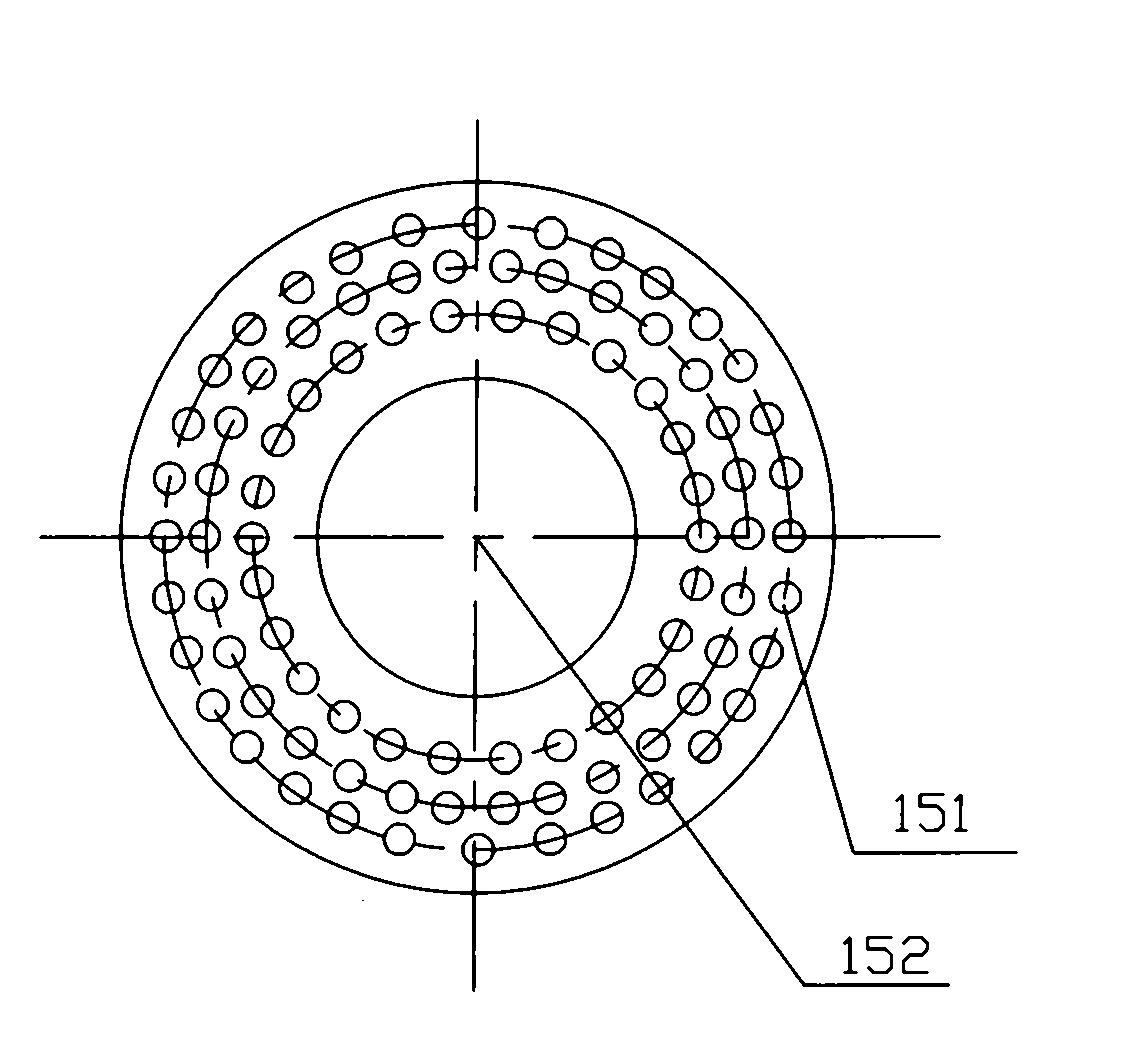

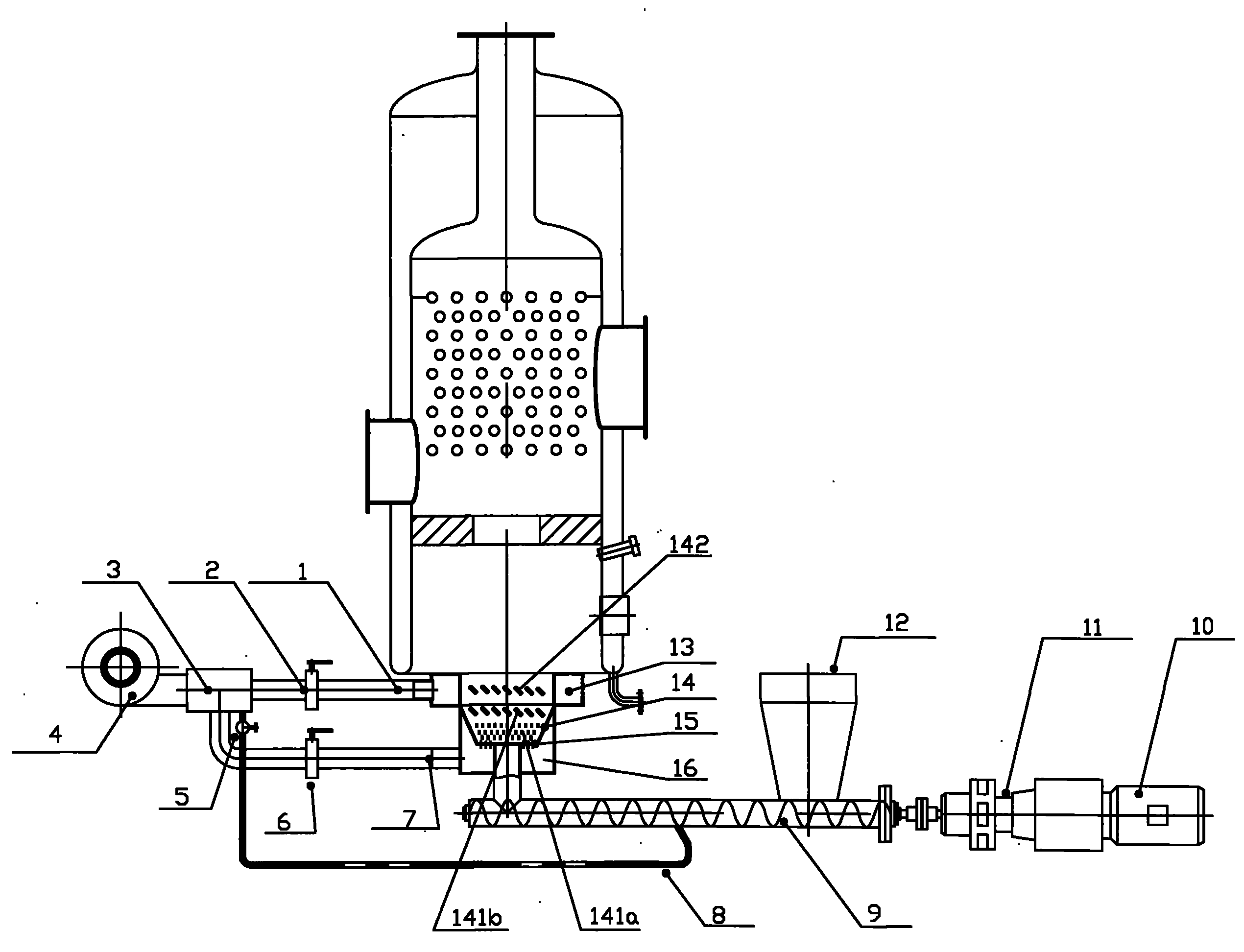

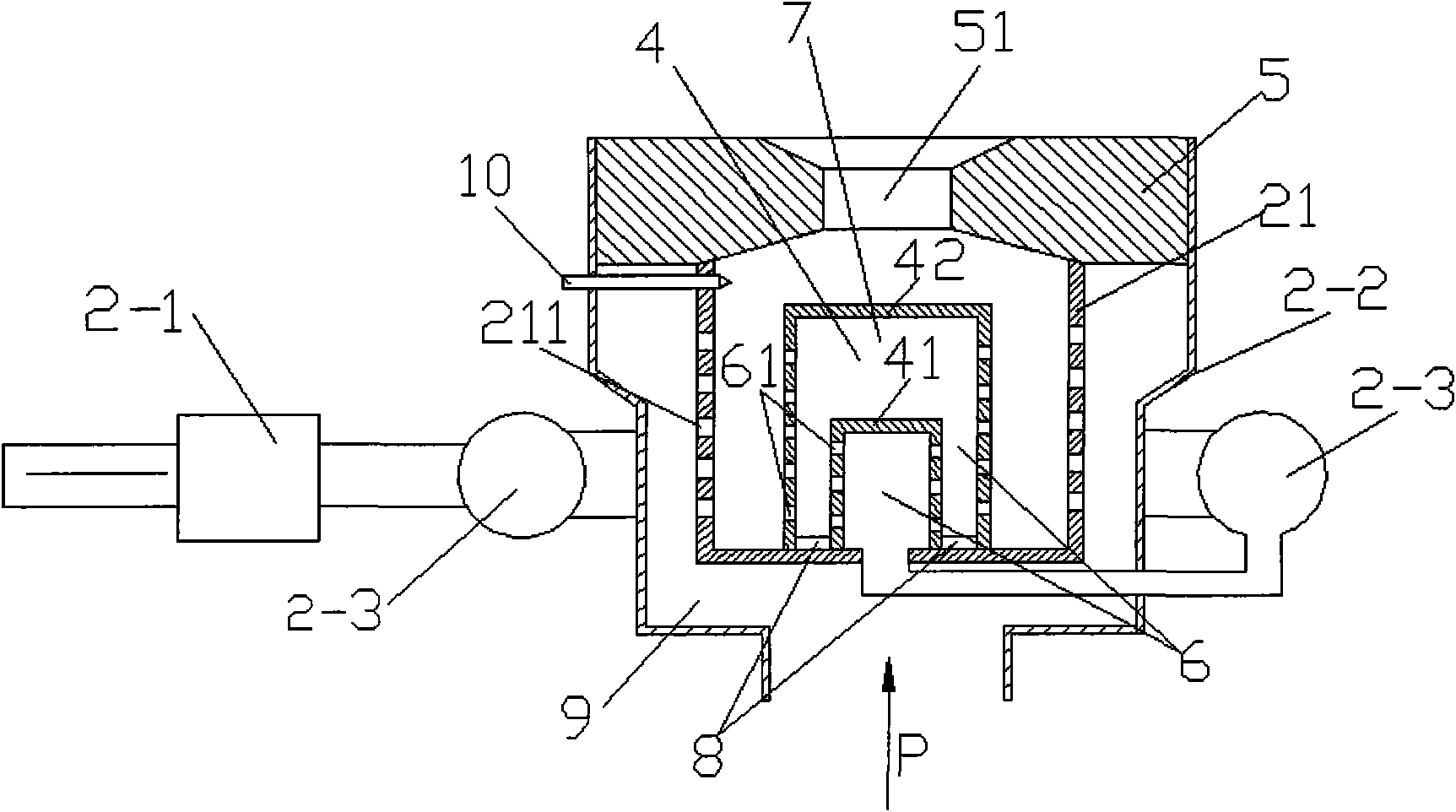

Biomass gasification fired boiler

InactiveCN101666492ASimple designReduce labor intensityFluidized bed combustionCombined combustion mitigationBiomass fuelsMethane

The invention relates to a biomass gasification fired boiler. The biomass gasification fired boiler can lead biomass fuel to generate combustible gases such as carbon monoxide, dimethylmethane, methane and the like without adding any chemical combustion improvers by adopting the principle of fluidized combustion through heat energy reaction, convert the biomass fuel into excellent combustible gases through preheating and dry distillation; and the biomass fuel is fully mixed with air through the design of primary air, secondary air and a tuyere to completely achieve smokeless, dustless and nuisanceless gas emission. In addition, the design of an underneath type spiral feeding system further improves the integral design of the boiler; and the biomass gasification fired boiler has more scientific feeding, is environment-friendly, and can greatly reduce the labor intensity of workers and improve the working environment.

Owner:张建超 +2

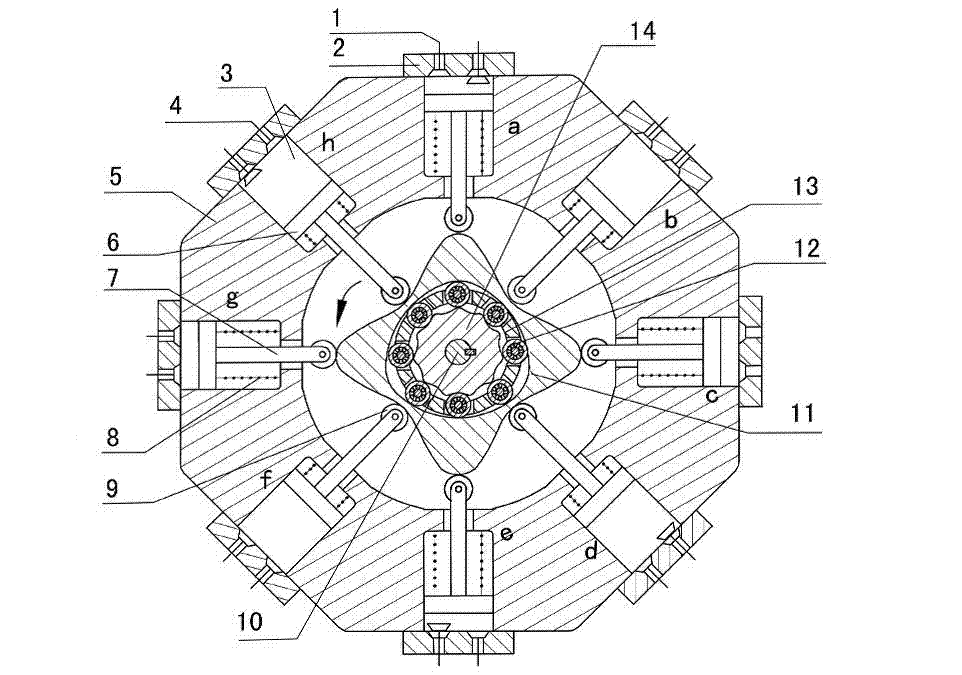

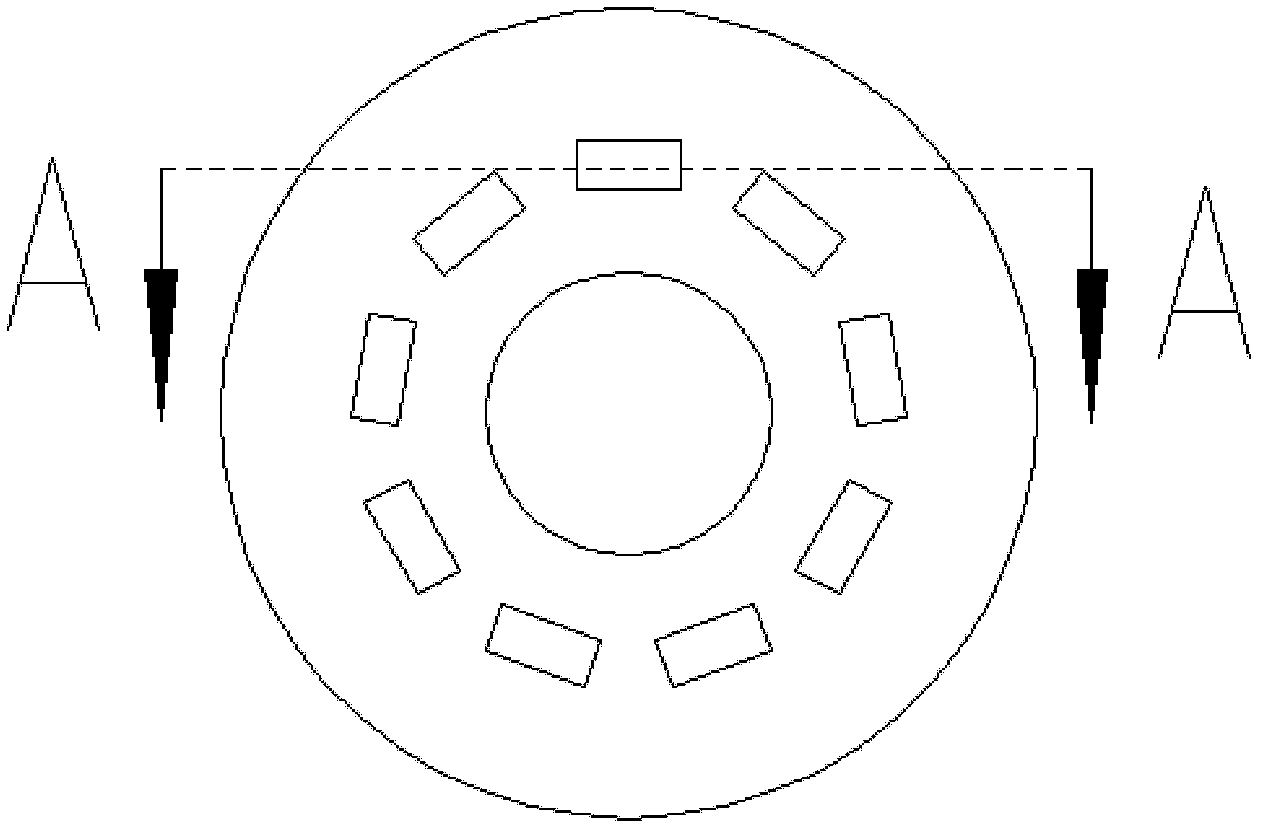

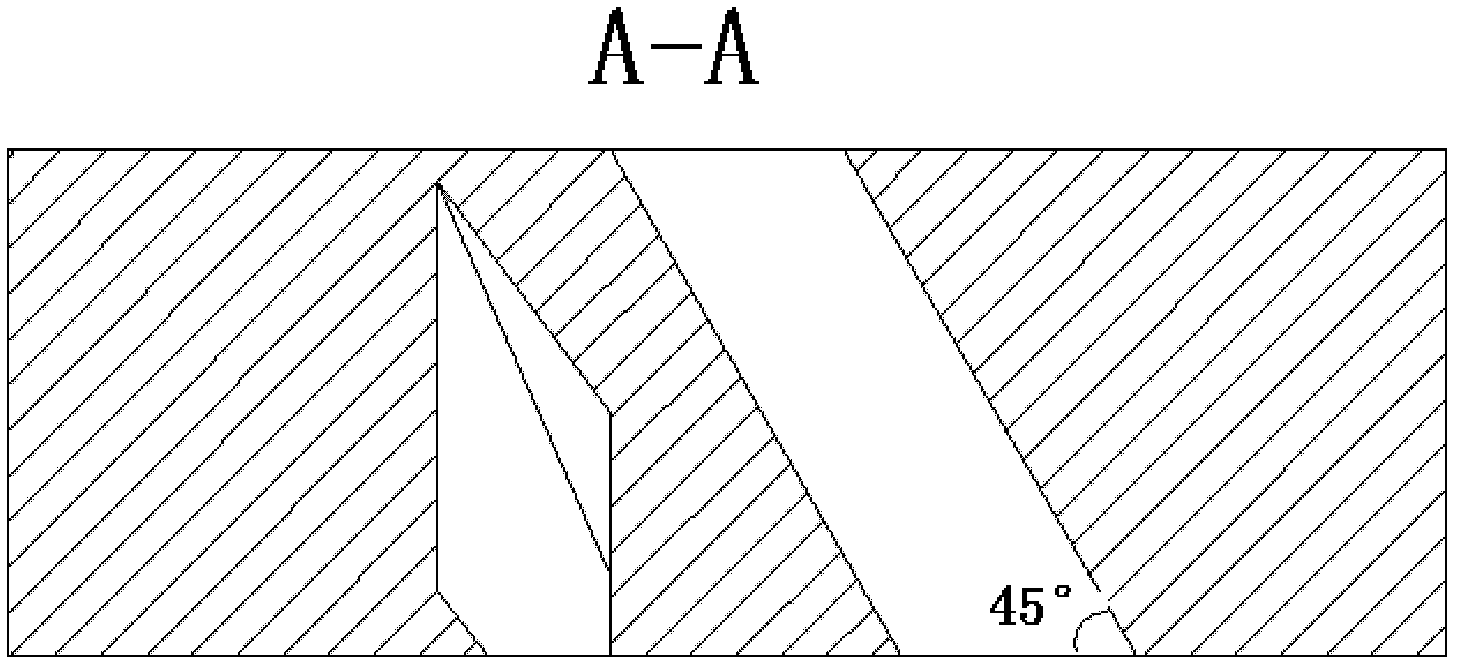

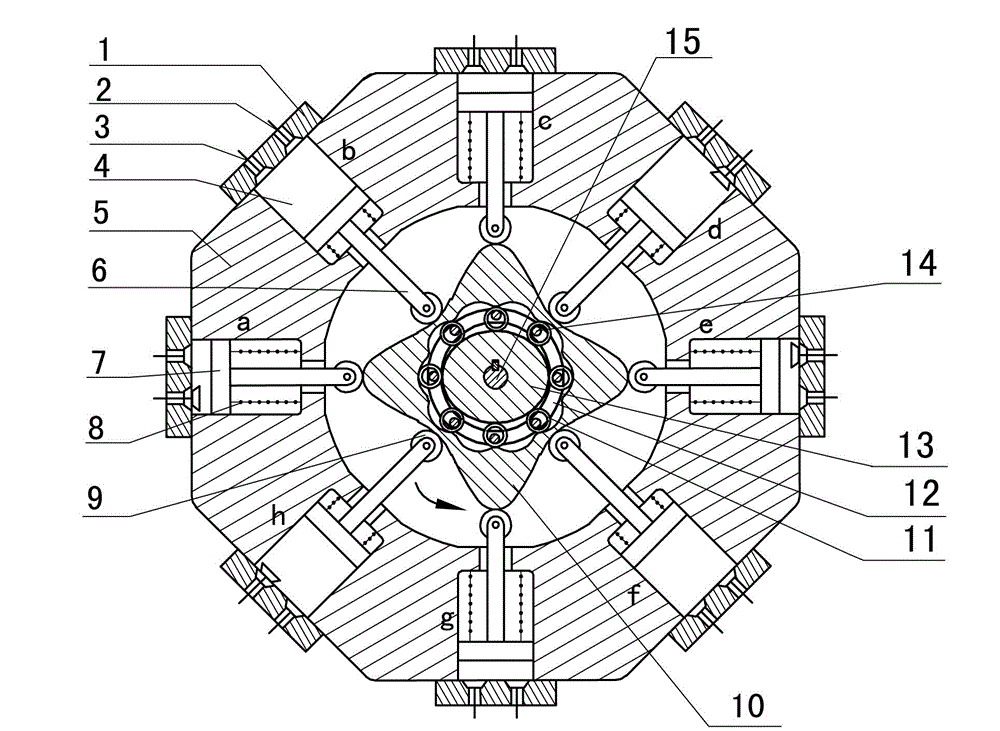

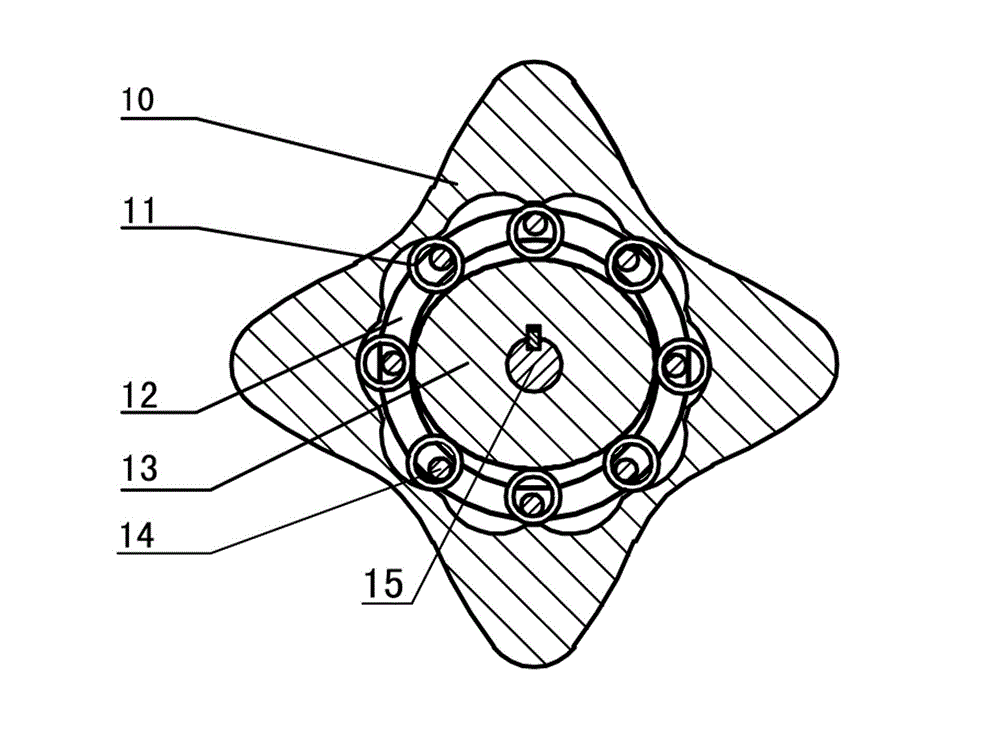

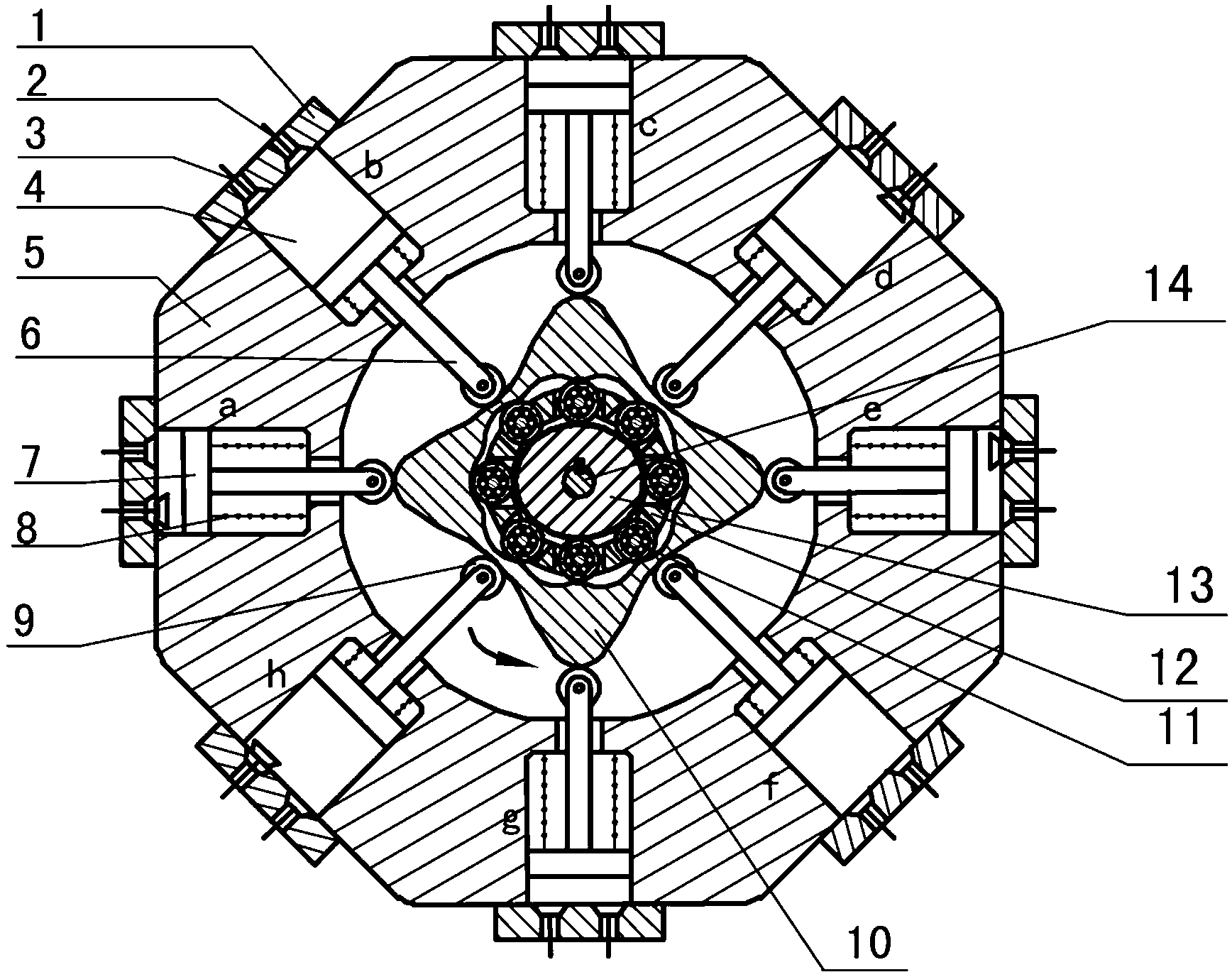

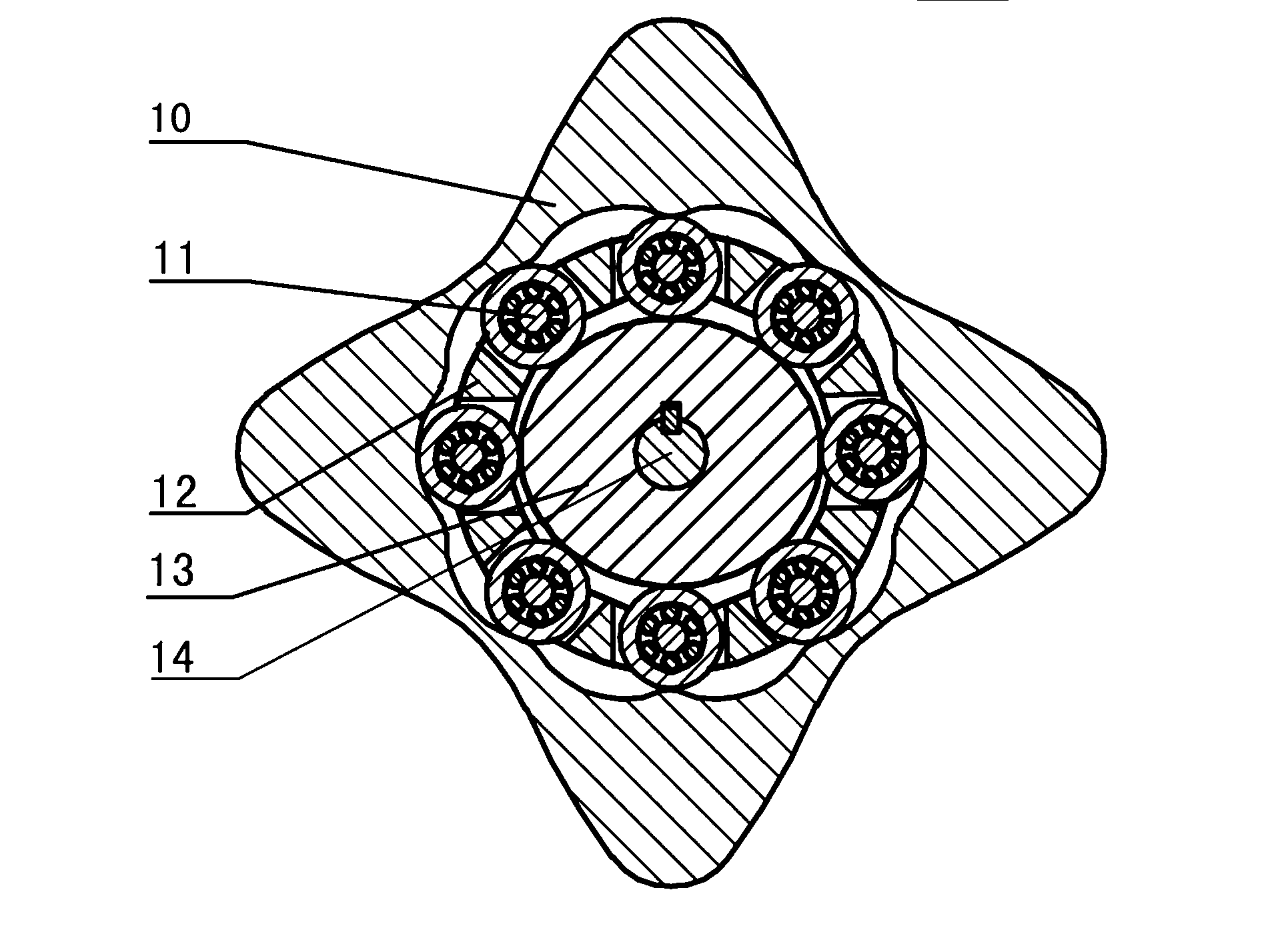

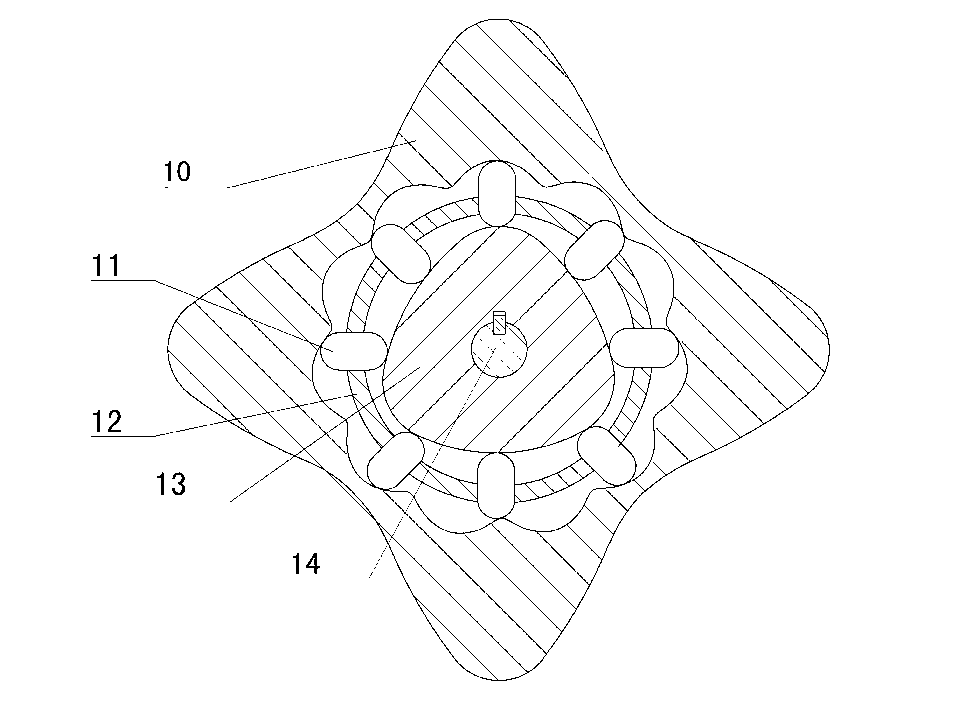

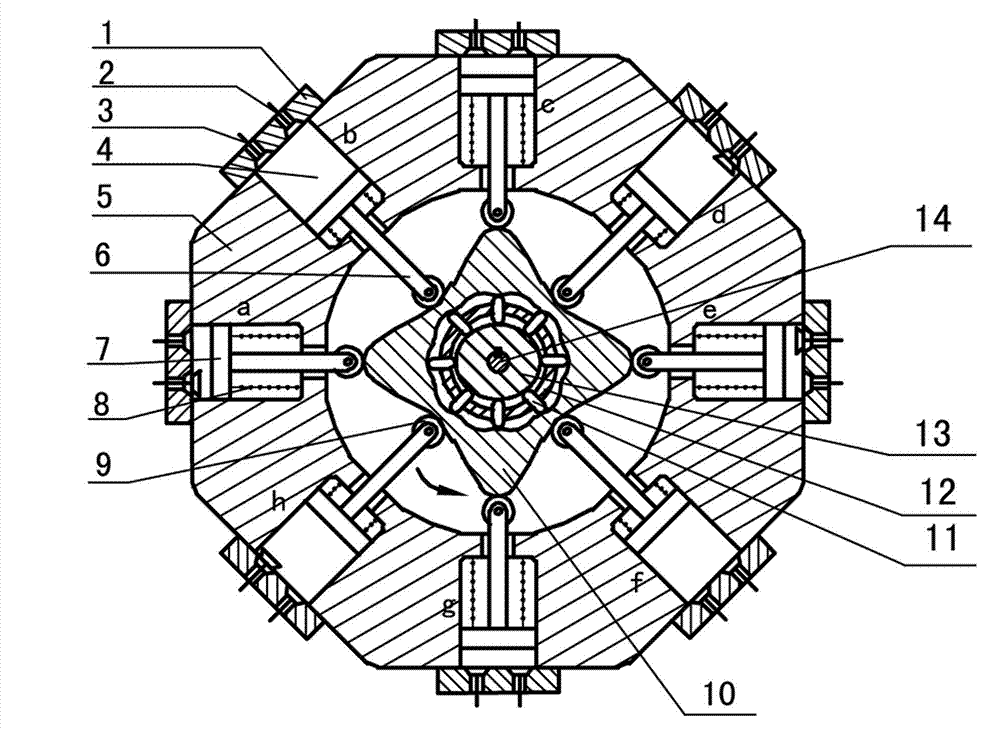

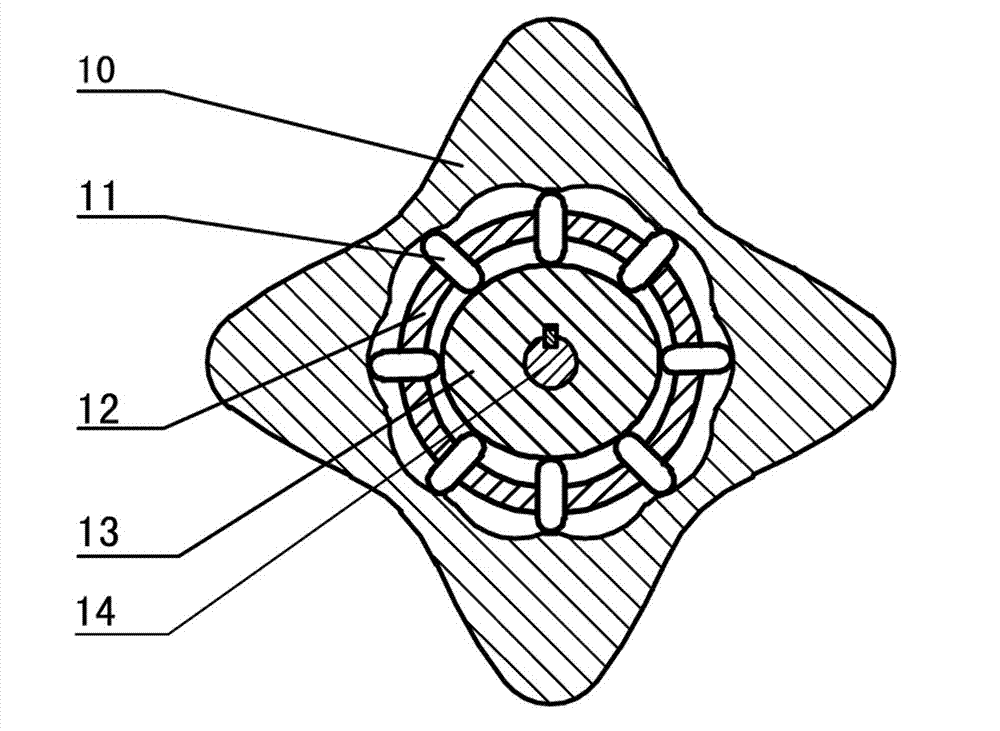

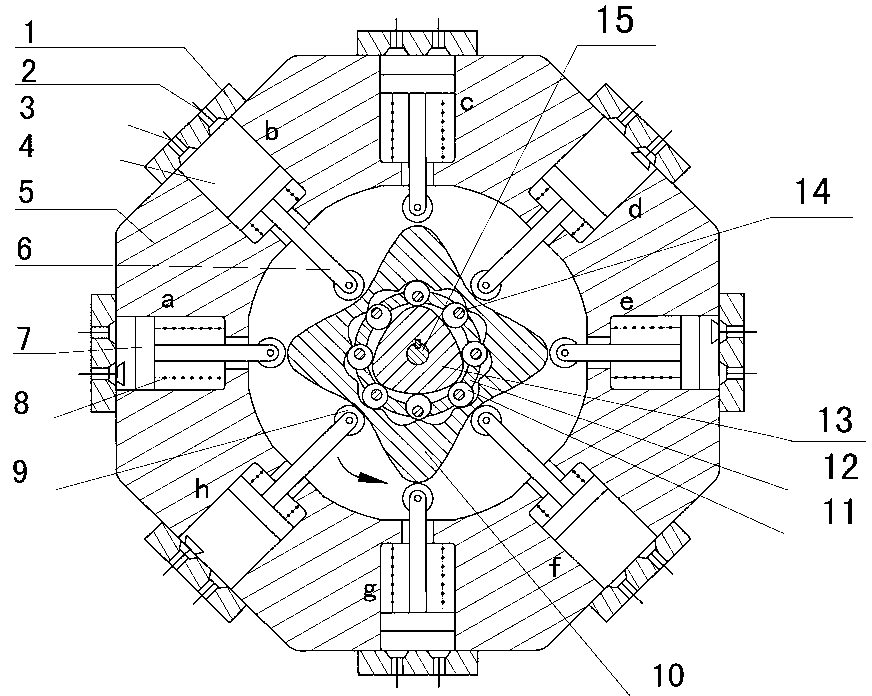

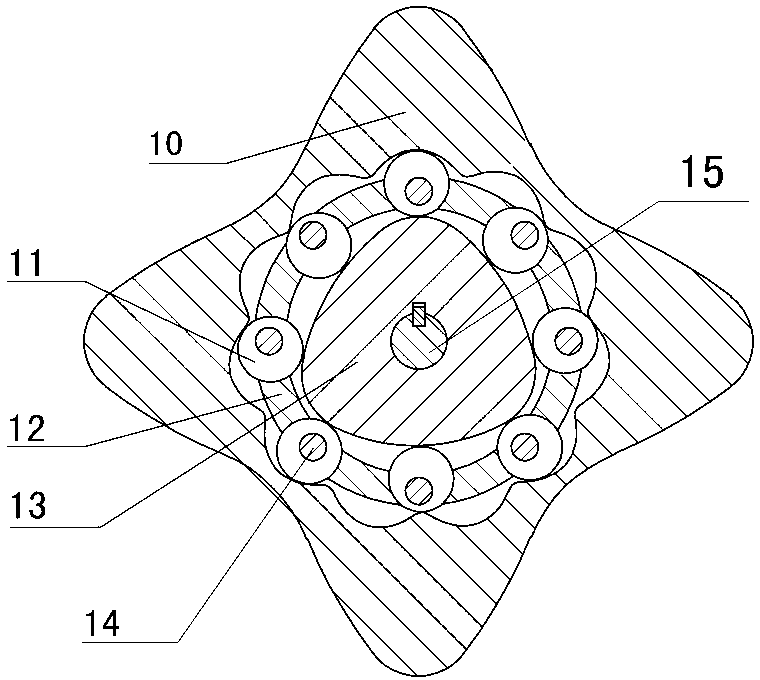

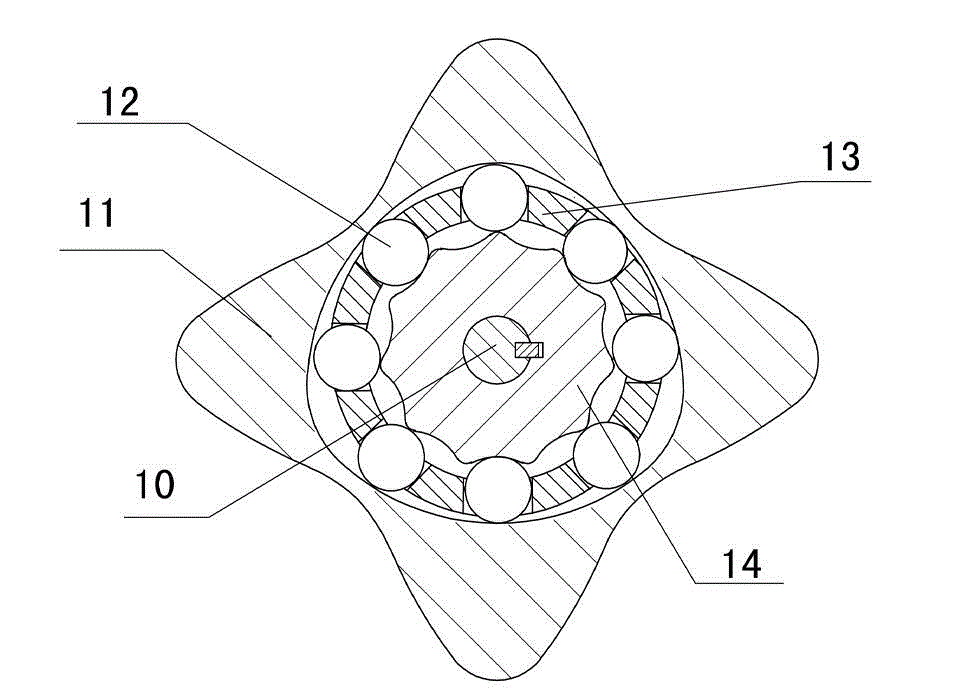

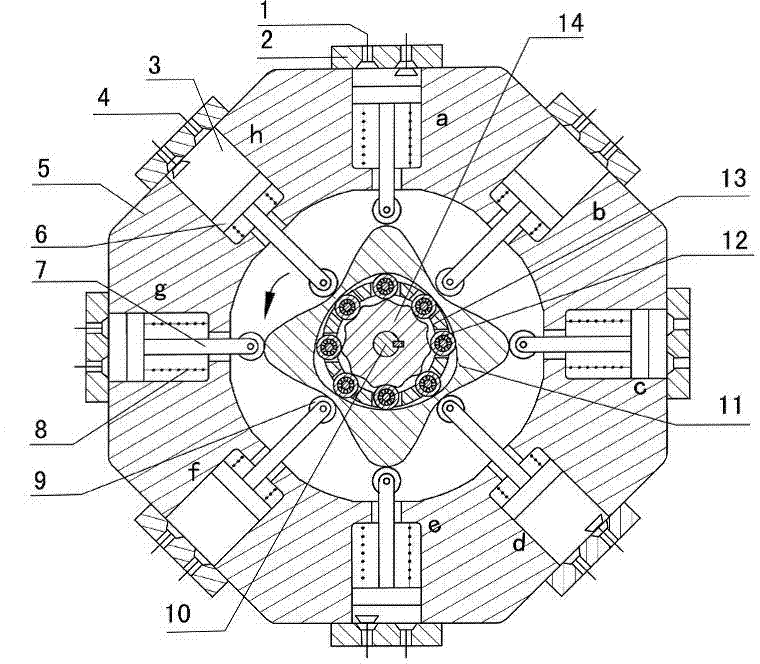

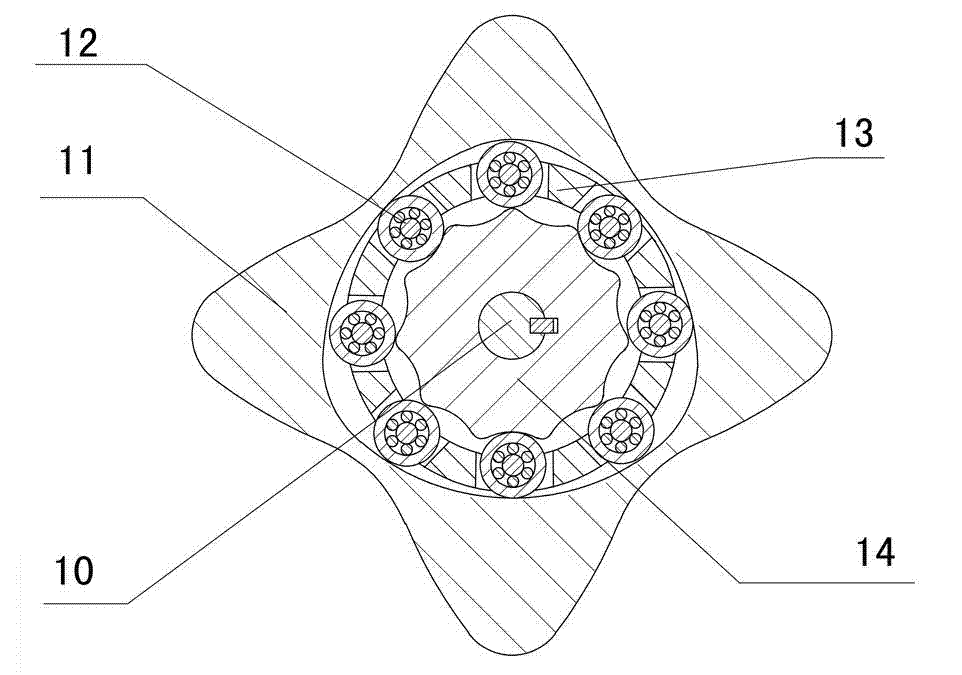

Outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine

The invention discloses an outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine, relating to the field of fuel gas power and belonging to a multi-cylinder internal-combustion engine. The invention provides a novel internal-combustion engine; eight cylinders are distributed on the periphery of an outer convex inner multiphase inner cam symmetrically in a ring shape, so that a resultant force of the outer convex inner multiphase inner cam is zero; each cylinder piston directly acts on the outer convex inner multiphase inner cam through a push rod; and power is transmitted to an output shaft connected with a central wheel key by the outer convex inner multiphase inner cam through arbitrary gear difference inner cam rolling moving movable gear transmission. With the adoption of the internal-combustion engine, a connecting rod and a crank shaft in the traditional internal-combustion engine are saved; an outer convex multiphase inner cam rolling moving transmission mechanism has the characteristics of having no eccentric mass, and having an inertia force and working load self-balancing; the rotating speed of the output shaft depends on transmission ratio of movable gear transmission; when a movable gear frame is fixed, output by a central wheel is in low speed and large torque; and the internal-combustion engine can be widely applied to the fields of high-power engineering machinery and military and the like, such as excavators and armored cars. The internal-combustion engine is simple and compact in structure, small in axial size, self-balancing in stress, and stable in rotating.

Owner:SICHUAN UNIV

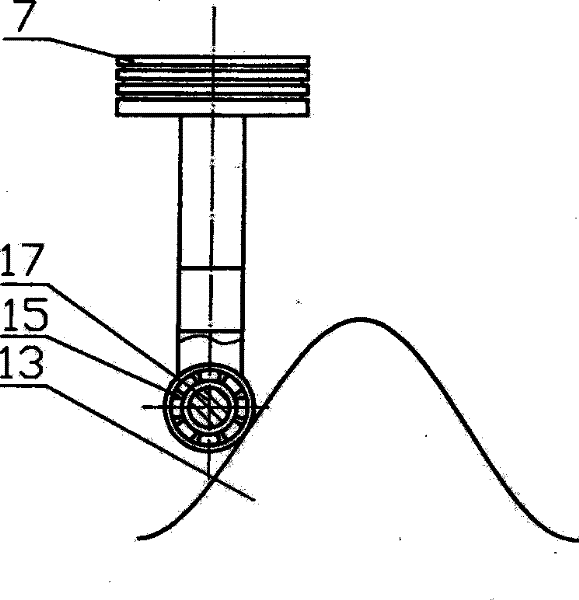

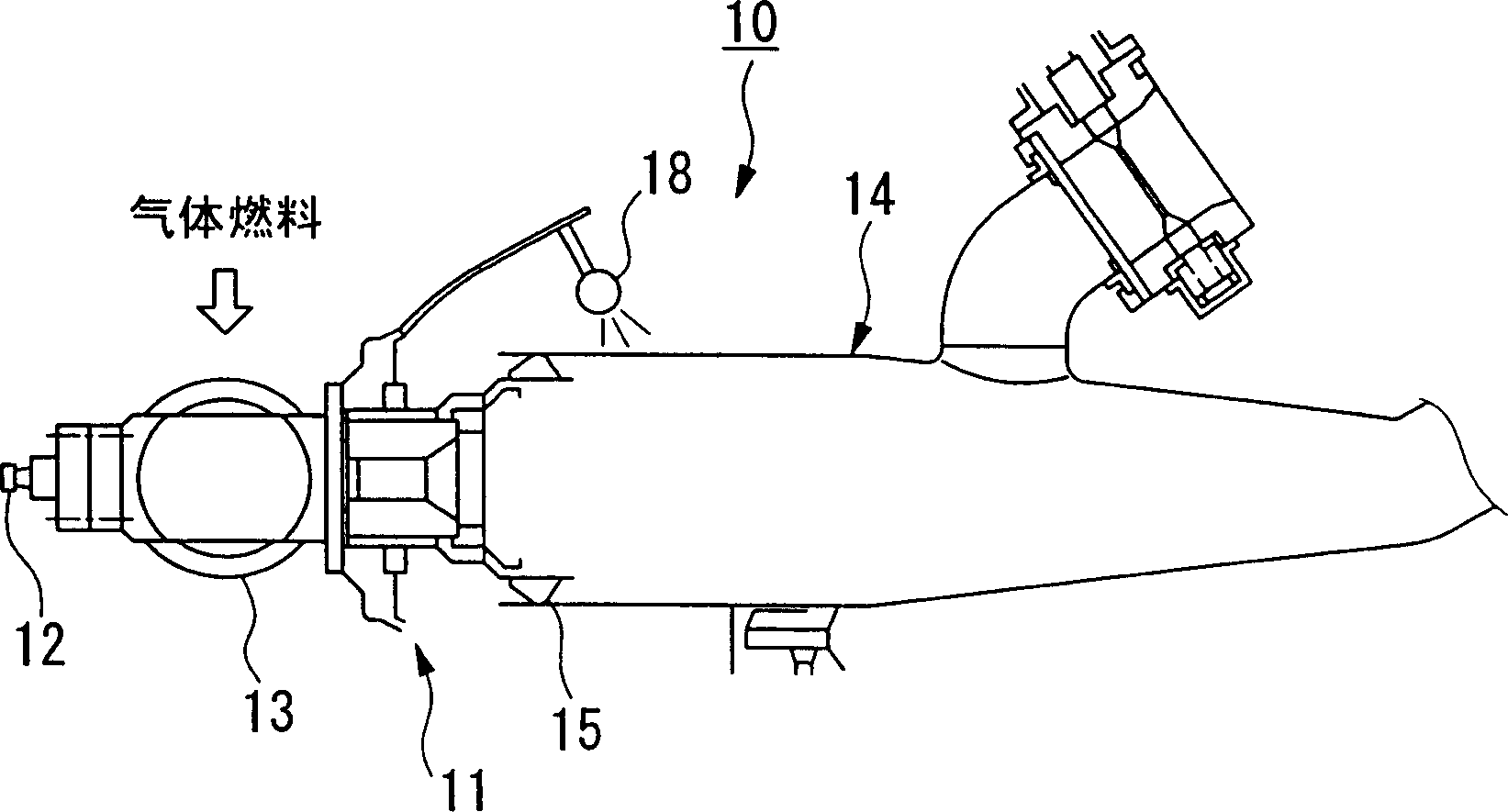

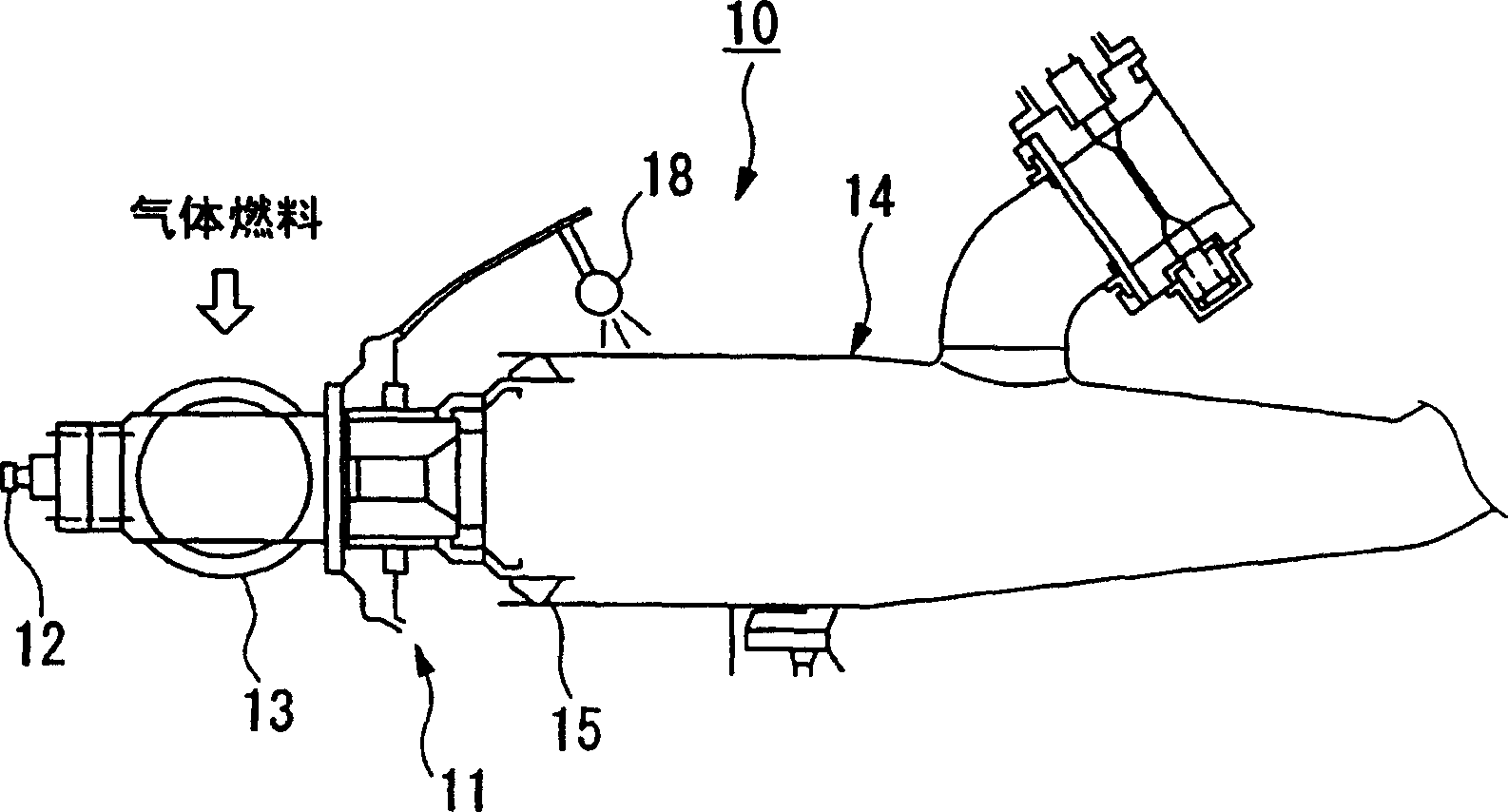

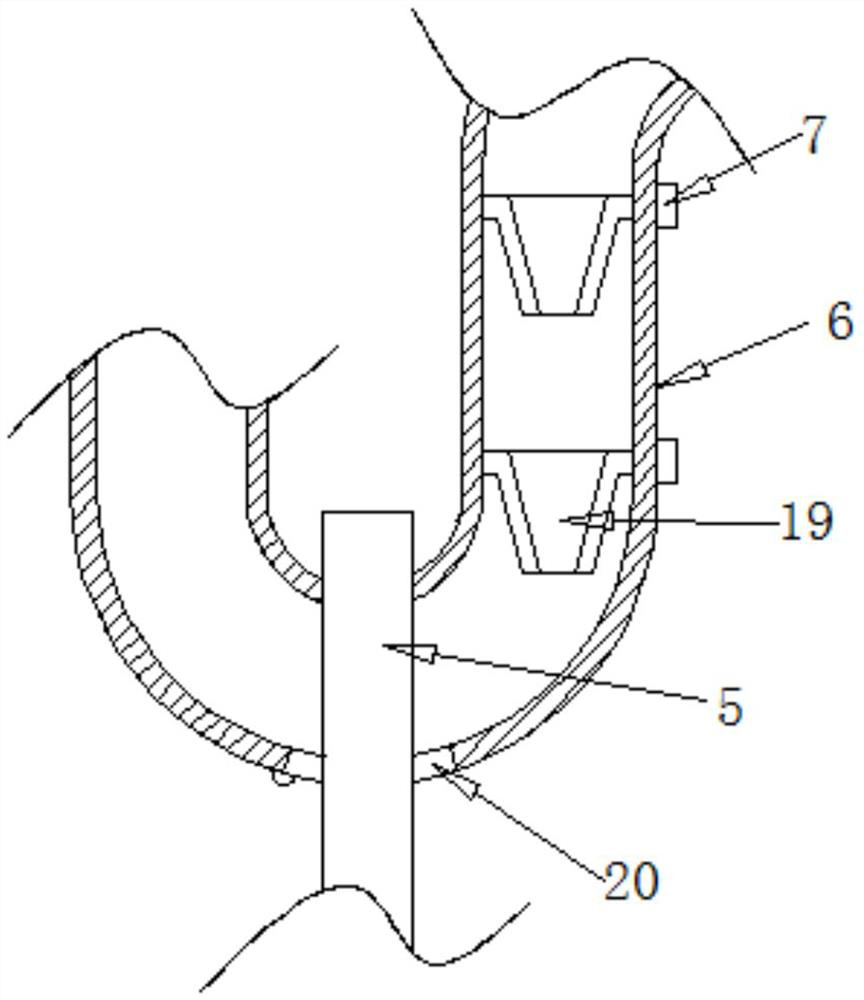

Internal rotational flow dual fuel nozzle for chemical regenerative cycle

InactiveCN102538016APerfect combustionShorten the lengthContinuous combustion chamberProduct gasRotational flow

The invention aims to provide an internal rotational flow dual fuel nozzle for a chemical regenerative cycle. The nozzle comprises a nozzle outer wall, an oil circuit pipeline, a gas spray hole, an oil spray hole and a rotational flow disk, wherein the oil circuit pipeline is arranged in the nozzle outer wall; a gas circuit cavity is formed between the oil circuit pipeline and the nozzle outer wall; the rotational flow disk is arranged between the oil circuit pipeline and the nozzle outer wall and divides the gas circuit cavity into a gas circuit front cavity and a gas circuit rear cavity; the gas circuit cavity is communicated with the gas spray hole; and the oil circuit pipeline is communicated with the oil spray hole. After a gas fuel sprayed from the nozzle is combusted, an internal rotational flow field can be formed, mixing is enhanced, combustion in a combustion chamber in the chemical regenerative cycle is intensified, the wall surface of a flame tube cannot be combusted, and the aims of combusting more fuels in a smaller space and shortening flame length are fulfilled.

Owner:三亚哈尔滨工程大学南海创新发展基地

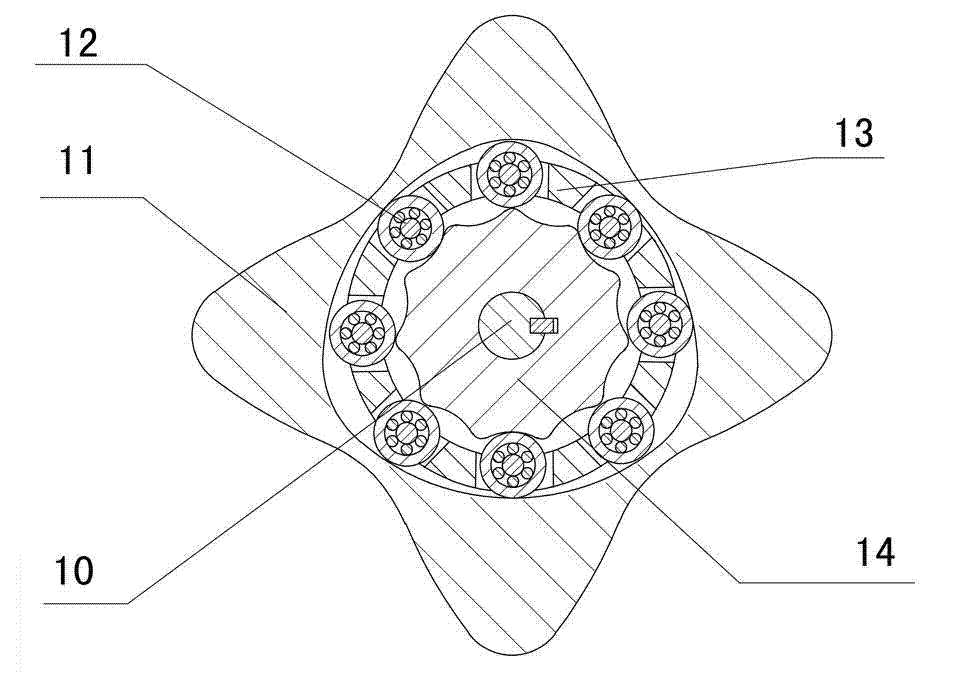

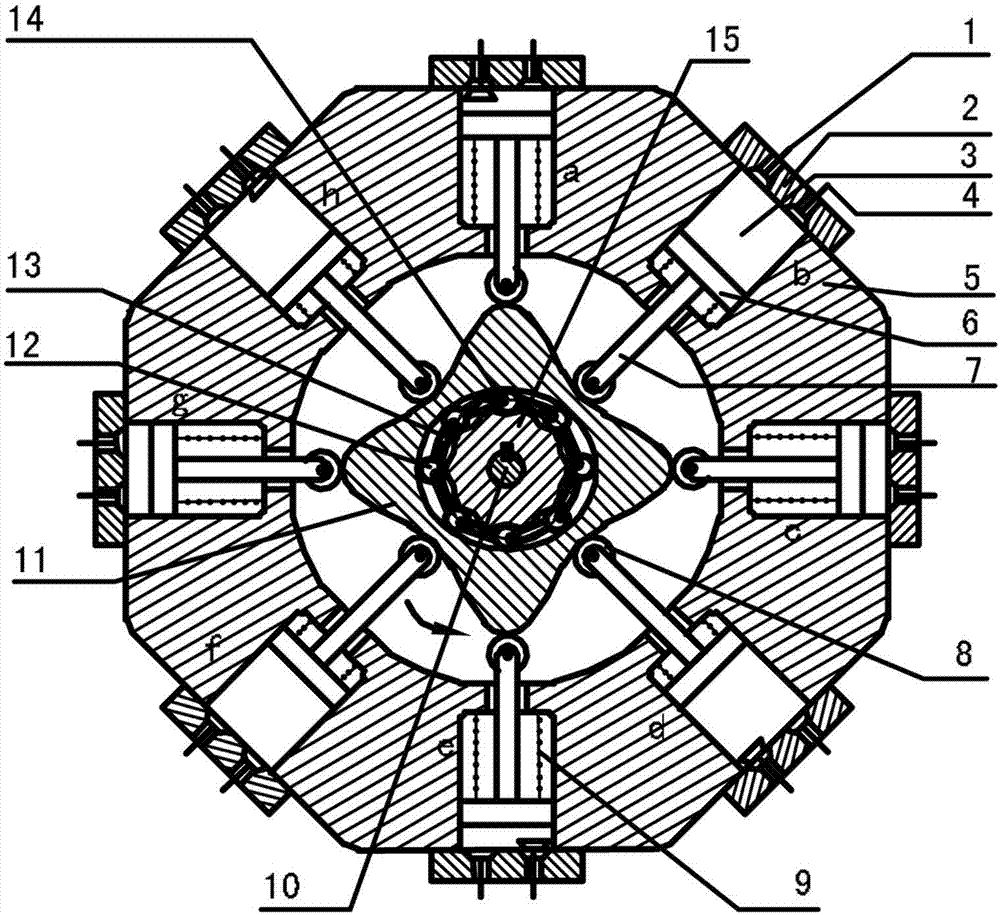

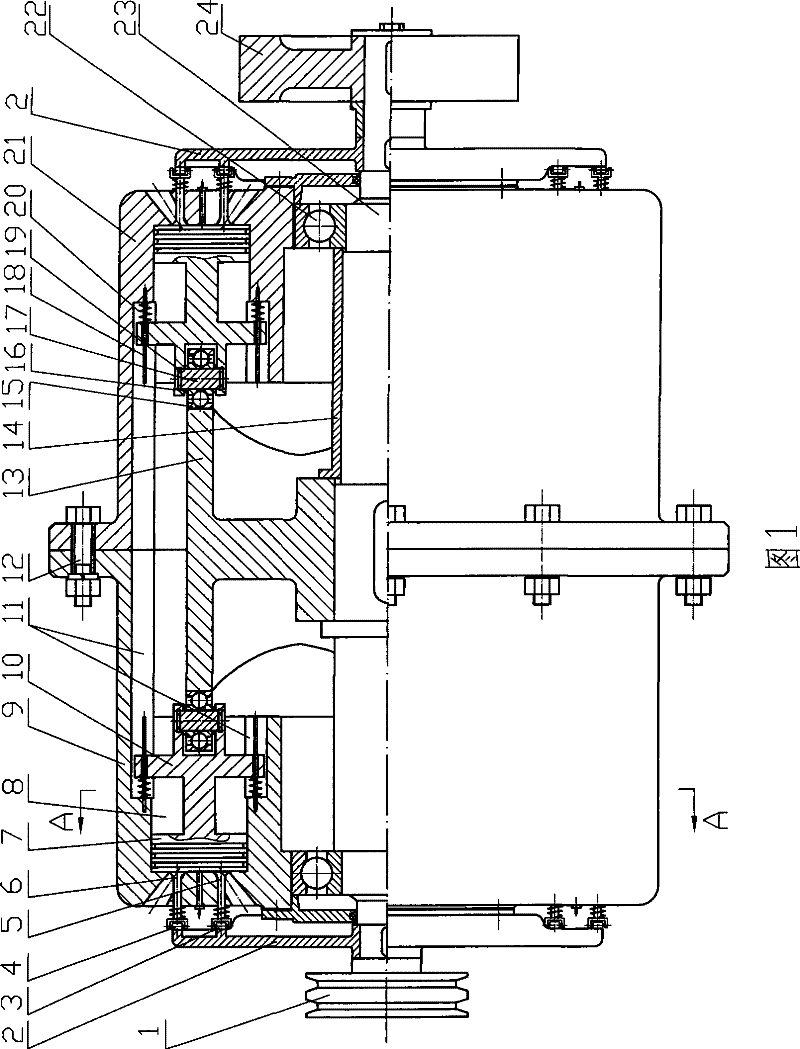

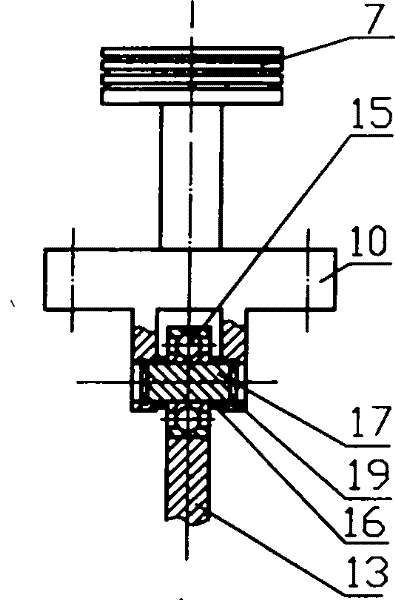

Two-phase outer cam sleeve type high-rotational-speed internal-combustion engine

InactiveCN102877942AHigh speed outputReduce axial sizeGearingMachines/enginesEngineeringInternal combustion engine

The invention discloses a two-phase outer cam sleeve type high-rotational-speed internal-combustion engine, and relates to the field of power of fuel gas. The invention provides a novel internal-combustion engine. Eight cylinders are annularly, symmetrically and uniformly distributed around an outwards convex inner gear ring, so that resultant force from which the outwards convex inner gear ring is suffered is zero; pistons of the cylinders directly act on the outwards convex inner gear ring through push rods; and power is transferred to an output shaft connected with a symmetric two-phase cam through a key by the outwards convex inner gear ring through the drive of a two-phase outer cam type sleeve oscillating tooth. By using the internal-combustion engine, a connecting rod and a crankshaft in a conventional internal-combustion engine are omitted; a two-phase outer cam sleeve driving mechanism of the outwards convex inner gear ring of the internal-combustion engine does not have an eccentric mass; the internal-combustion engine has the characteristic of the self balancing of inertia force and a working load; the rotational speed of the output shaft depends on the drive ratio of the drive of the oscillating tooth; if a dowel pin frame is fixedly arranged, the symmetric two-phase cam carries out output at a high speed; the internal-combustion engine can be widely applied to the field of high rotational speeds, such as engines of helicopters, and miniature engines; and when an output rotational speed is constant, the emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, small in axial dimension and self-balancing in stress, and is stable to run.

Owner:SICHUAN UNIV

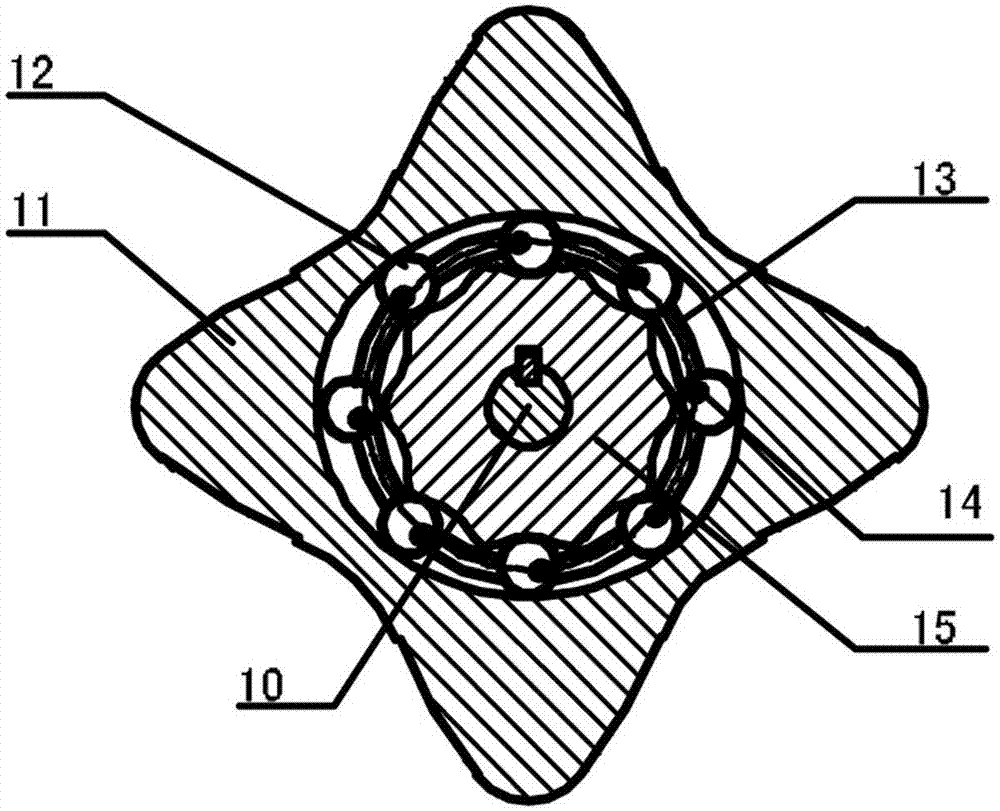

Two-phase inner cam type swinging transmission internal combustion engine

InactiveCN102828824AForce self-balancingLarge transmission ratioGearingMachines/enginesLow speedEngineering

The invention provides a two-phase inner cam type swinging transmission internal combustion engine, which relates to the field of gas motive power and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, eight air cylinders are annularly, symmetrically and uniformly distributed around an outer convex inner two-phase inner cam, the resultant force of the outer convex inner two-phase inner cam is zero, an air cylinder piston directly acts on the outer convex inner two-phase inner cam through a push rod, and the motive power is transferred to an output shaft connected with a center wheel key through a two-phase inner cam type swinging movable tooth via the outer convex inner two-phase inner cam. The internal combustion engine has the characteristics that a connecting rod and a crankshaft in the traditional internal combustion engine are omitted, and an outer convex inner two-phase inner cam type swinging transmission mechanism does not have the eccentric mass, and has the inertia force and work load self balance characteristic. The rotating speed of the output shaft depends on the transmission ratio of the movable tooth transmission, when the movable tooth frame is fixed, a center wheel realizes low-speed and large-torque output, and the internal combustion engine can be widely applied to engineering machinery, armored car and the like with high-powder requirements. The internal combustion engine has the advantages that the structure is simple and compact, the axial dimension is small, the self balance of the stress is realized, and the operation is stable.

Owner:SICHUAN UNIV

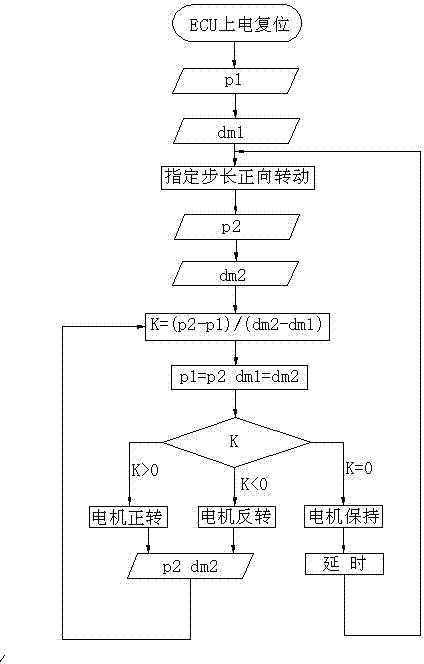

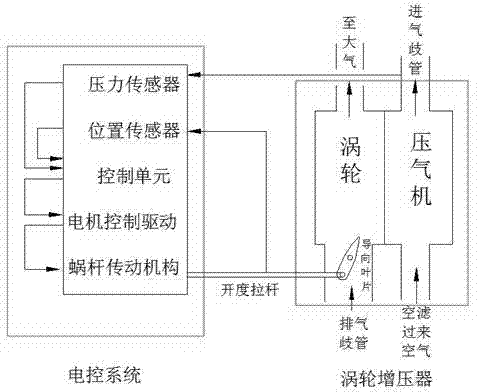

Intelligent, quick and accurate electric control system for turbo-charging adjustment

InactiveCN103485905APerfect combustionIncrease powerInternal combustion piston enginesEngine controllersImpellerGas compressor

The invention discloses an intelligent, quick and accurate electric control system for turbo-charging adjustment. An electric control unit (ECU) which is arranged in an electric control actuator is used for performing comparison operation on a pressure signal transmitted by a pressure sensor with a guide vane position signal transmitted by a position sensor, performing prediction according to a front-three-point difference method according to a pressure value under a current state to realize deviation comparison between a guide vane position corresponding to a pressure value under the next step length target point and a pressure value under a current target position, and giving an instruction to a motor control driving unit according to an inlet pressure maximization rule after the comparison operation, so that the forward and reverse rotation or retaining motion of a motor is realized, and a turbine guide vane and a turbine rotor are in an optimally matched state. Compared with a MAP control criterion determined according to a theoretic method or a test method, a control program criterion has the advantage that errors caused by the manufacturing deviation of a gas compressor impeller, a turbine impeller, a supporting shaft system of a rotor and the like are avoided.

Owner:哈尔滨安龙迪环保科技有限公司

Biomass gasification fired boiler

InactiveCN101666492BSimple designReduce labor intensityFluidized bed combustionCombined combustion mitigationWorking environmentCombustible gas

The invention relates to a biomass gasification fired boiler. The biomass gasification fired boiler can lead biomass fuel to generate combustible gases such as carbon monoxide, dimethylmethane, methane and the like without adding any chemical combustion improvers by adopting the principle of fluidized combustion through heat energy reaction, convert the biomass fuel into excellent combustible gases through preheating and dry distillation; and the biomass fuel is fully mixed with air through the design of primary air, secondary air and a tuyere to completely achieve smokeless, dustless and nuisanceless gas emission. In addition, the design of an underneath type spiral feeding system further improves the integral design of the boiler; and the biomass gasification fired boiler has more scientific feeding, is environment-friendly, and can greatly reduce the labor intensity of workers and improve the working environment.

Owner:张建超 +2

Systems and methods for boost control

InactiveUS10041448B2Reduce nitrogen oxide emissionsImprove fuel economyElectrical controlInternal combustion piston enginesSystem configurationExhaust gas recirculation

Methods and systems are provided for reducing turbo lag in an engine system configured with a cylinder dedicated for exhaust gas recirculation and distinct turbines coupled to the dedicated EGR cylinder and remaining engine cylinders. An air-fuel ratio of combustion in the dedicated cylinder is adjusted responsive to a tip-in event by providing blow-through air and additional fuel based on the amount of heat required to spin up a turbine coupled to the dedicated cylinder and provide the requested boost pressure. The approach enables turbo lag to be reduced while providing high EGR at high boost conditions.

Owner:FORD GLOBAL TECH LLC

Two-phase outer cam shock wave rolling transmission internal combustion engine

InactiveCN102937048AReduce axial sizeCompact structureValve drivesMachines/enginesShock waveExternal combustion engine

The invention provides a two-phase outer cam shock wave rolling transmission internal combustion engine and relates to the field of gas power. According to the novel internal combustion engine, eight cylinders are annularly symmetrically evenly distributed around a convex inner tooth ring, the resultant force which the convex inner tooth ring is subjected to is zero, and a cylinder piston directly acts on the convex inner tooth ring through a push rod, power is transmitted to an output shaft connected with a two-phase outer cam key by two-phase outer cam shock wave rolling oscillating tooth transmission through the convex inner tooth ring. According to the internal combustion engine, a connecting rod and a crankshaft in a traditional internal combustion engine are not required, a convex inner two-phase shock wave rolling transmission mechanism does not have eccentric mass and has the advantages of self balancing of inertia force and working load, and the rotating speed of the output shaft depends on the transmission ratio of oscillating tooth transmission. If an oscillating tooth brace is fixed, a two-phase outer cam performs high-speed output and can be widely applied to the fields requiring for high rotating speeds, such as helicopter engines and small generators, and discharge of harmful gas can be reduced when the output rotating speed is fixed. The internal combustion engine is simple and compact in structure, small in axial dimensions self-balancing in stress and runs stably.

Owner:SICHUAN UNIV

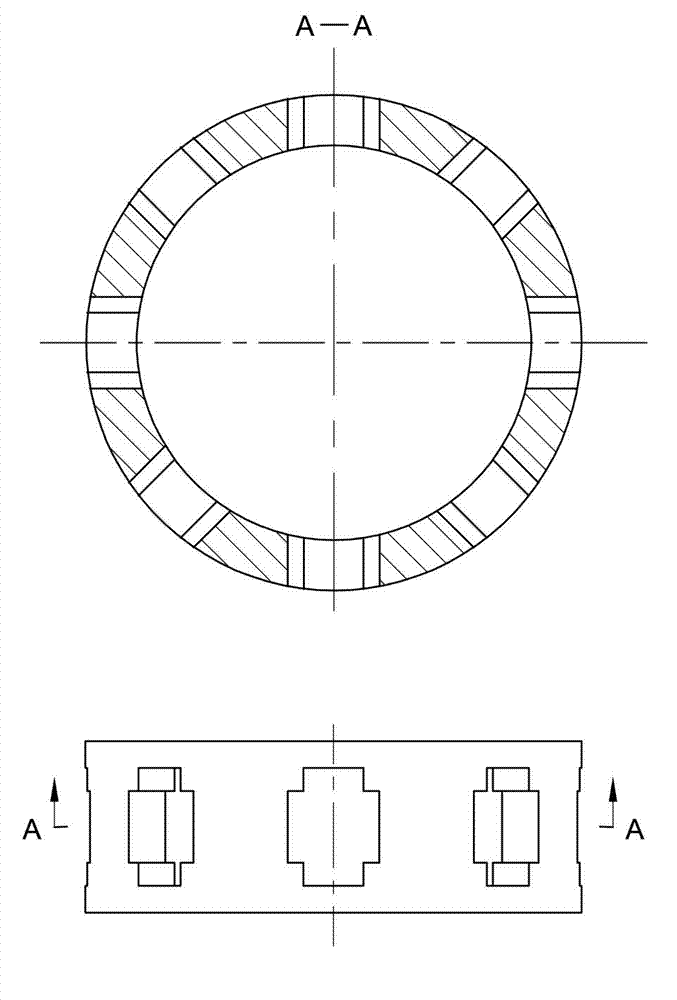

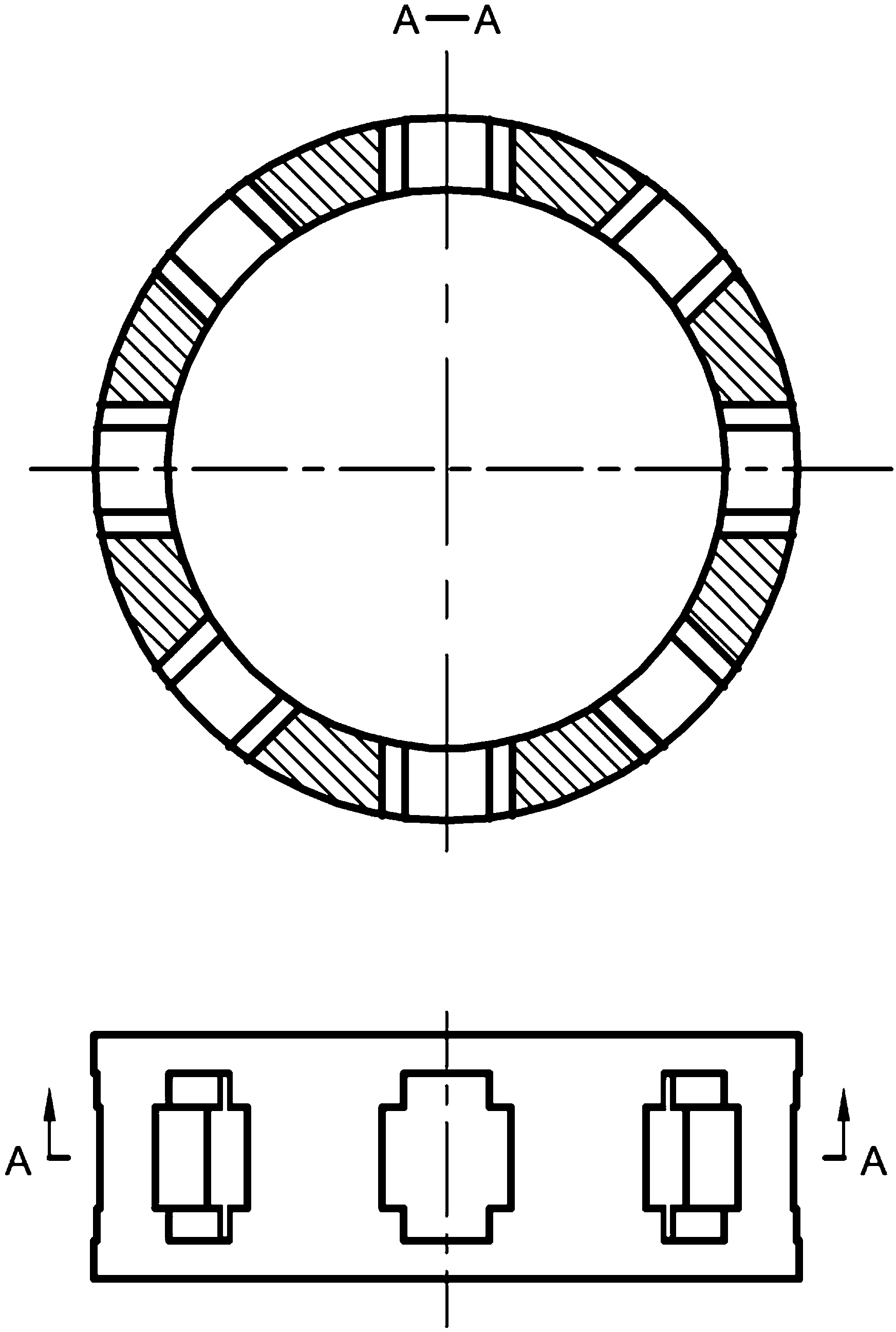

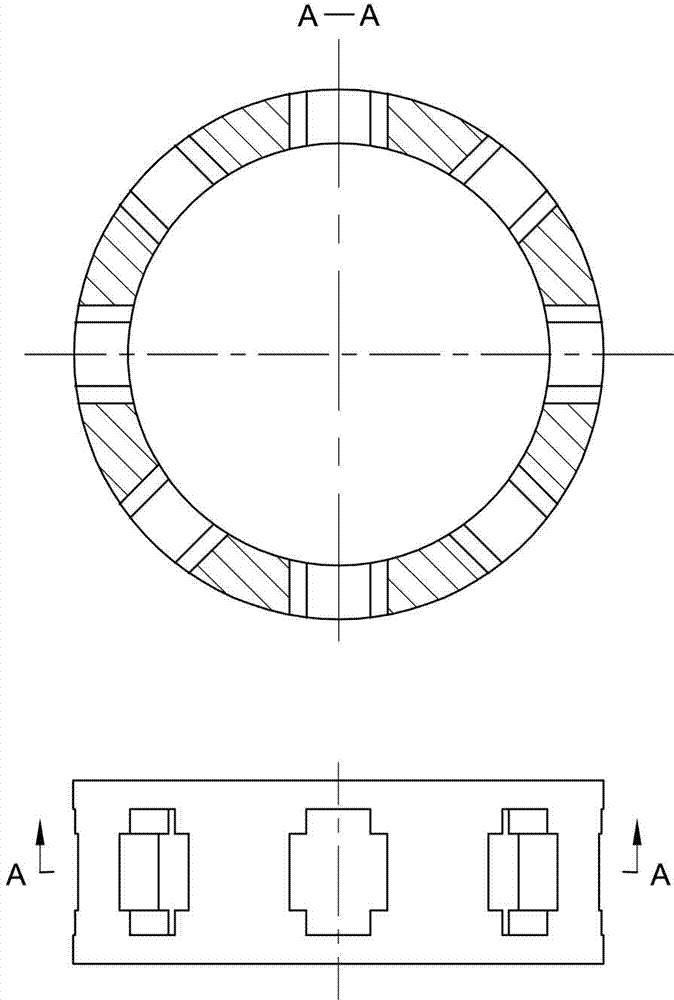

Cylinder double-face cam axial piston type crankless internal combustion engine

InactiveCN101392684BReduce noiseSmall shock and vibrationValve drivesMachines/enginesExhaust valveCombustion

The invention discloses a cylindrical double-track cam axial piston type crankless internal combustion engine, which relates to the technical field of internal combustion engines and is a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine; when pistons drive rollers arranged on the bottoms of the pistons for reciprocating movement, the rollers push a double-track cam fixed on a main shaft to rotate, and the power is output from the double-track cam through the main shaft. Outlines of two end surfaces of the double-track cam are in the form that wave crests correspond to wave crests, wave troughs correspond to wave troughs, and the two end surfaces are circumferentially symmetrical. Two groups of cylinders are symmetrically arranged at bothends of the double-track cam, and axis lines of the cylinders have equal distance to an axis line of the main shaft and are parallelly, circularly and evenly distributed. The pistons which have the same axis line and are symmetrically arranged with the spacing of 180 DEG C have the same working state, which ensures that the axial and radial composite force of the double-track cam and the main shaft are zero. A sliding rod at the bottom of each piston slides in a guide groove, which ensures that the side pressure of the piston is zero. Intake and exhaust valves of all the cylinders are intensively controlled by two distributing cams. The internal combustion engine has the characteristics of simple and compact structure, small volume, small impact vibration, steady operation, high power, long service life and so on.

Owner:SICHUAN UNIV

Three-in-one burning method for garbage

A garbage triad incineration method, of the garbage power generation boiler burning system technical field, includes the following technical technological process: a. mix the garbage with powder coal, the quantity added is 1-5% of garbage; b. add emulsifying agent and oil into water to create emulsified oil, with the quantity added of emulsifying agent and oil whose weight are 1-5% and 30-70% of water; c, the garbage mixed with powder coal is transferred into a boiler furnace cavity, burning, meanwhile, the emulsified oil prepared is injected to the boiler furnace cavity, burning. The invention uses garbage as base stock,and garbage, oil, powder coal combustion method, combines the advantages of oil and coal oxidizer, does good to making use of garbage, reducing coal quantity, cost and second pollution, saving energy, compared to the present technology.

Owner:ZHEJIANG LANTING HI TECH

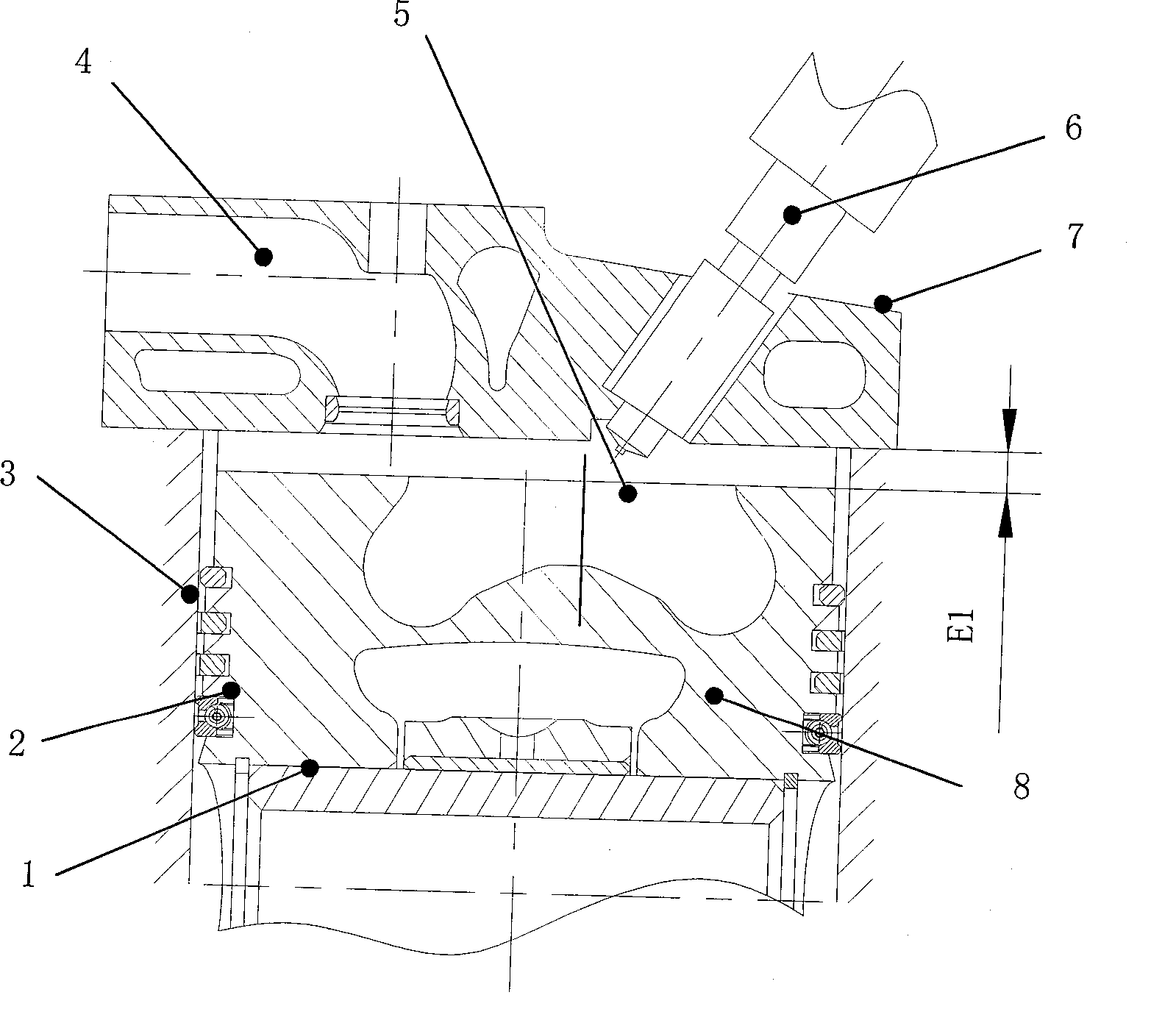

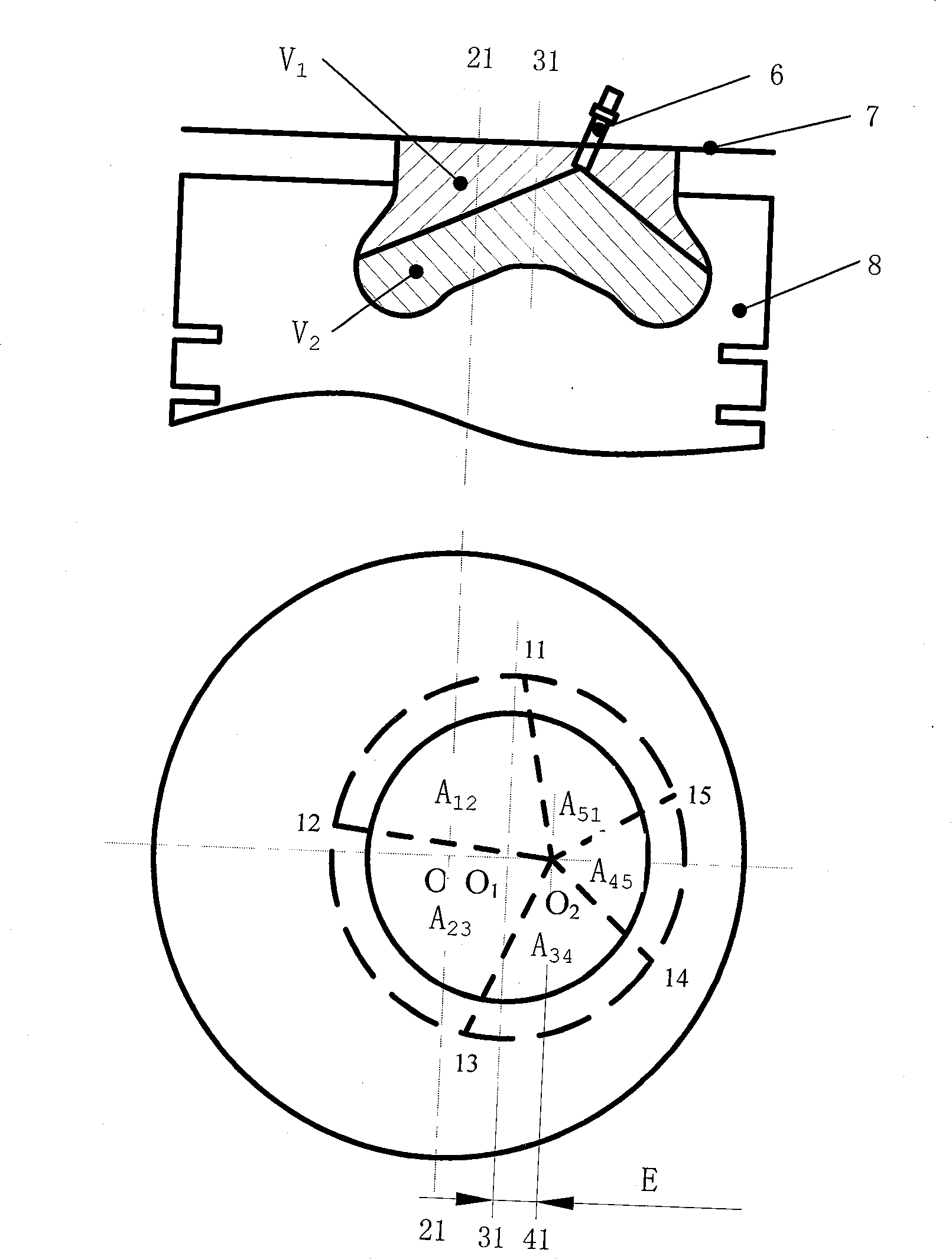

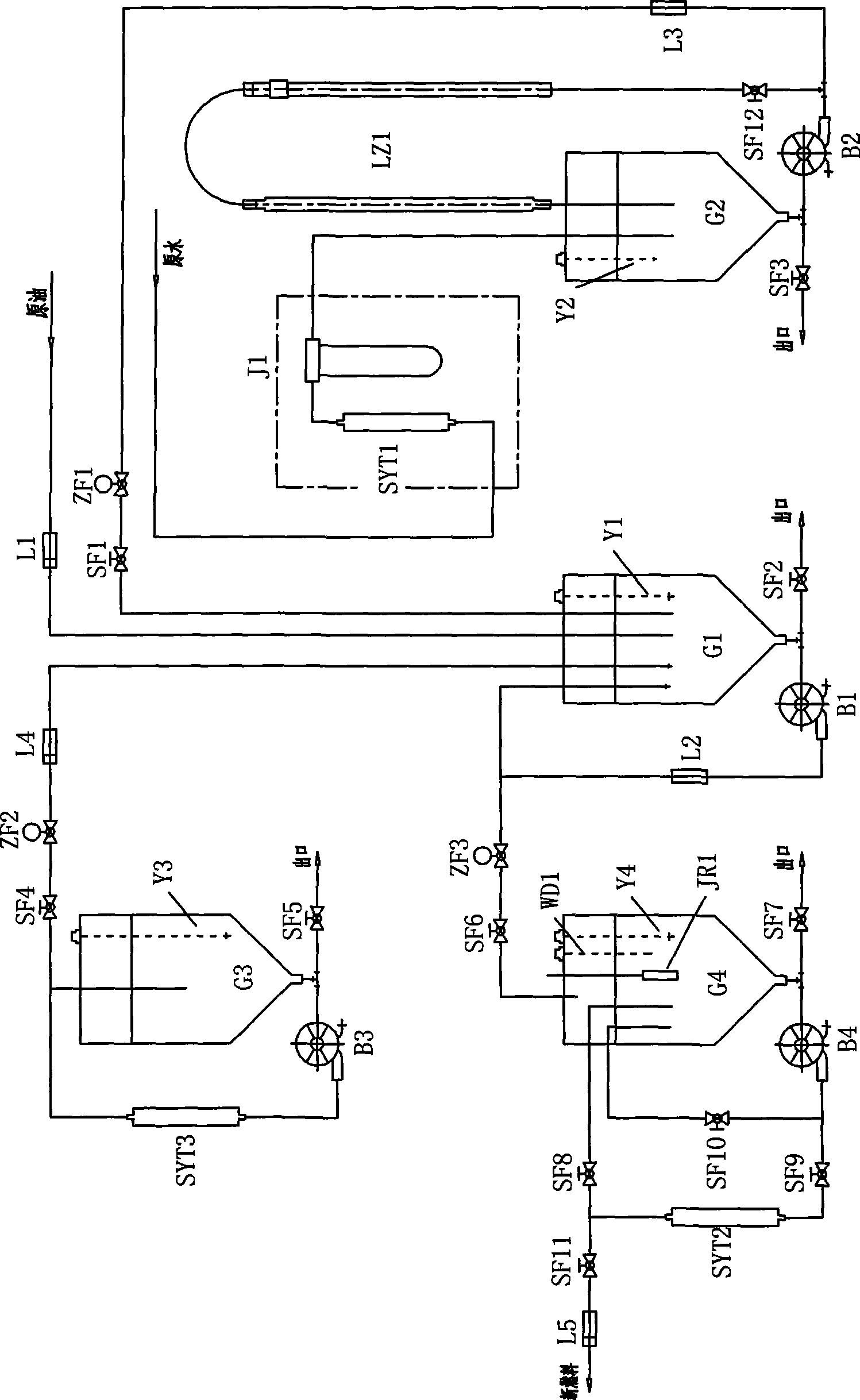

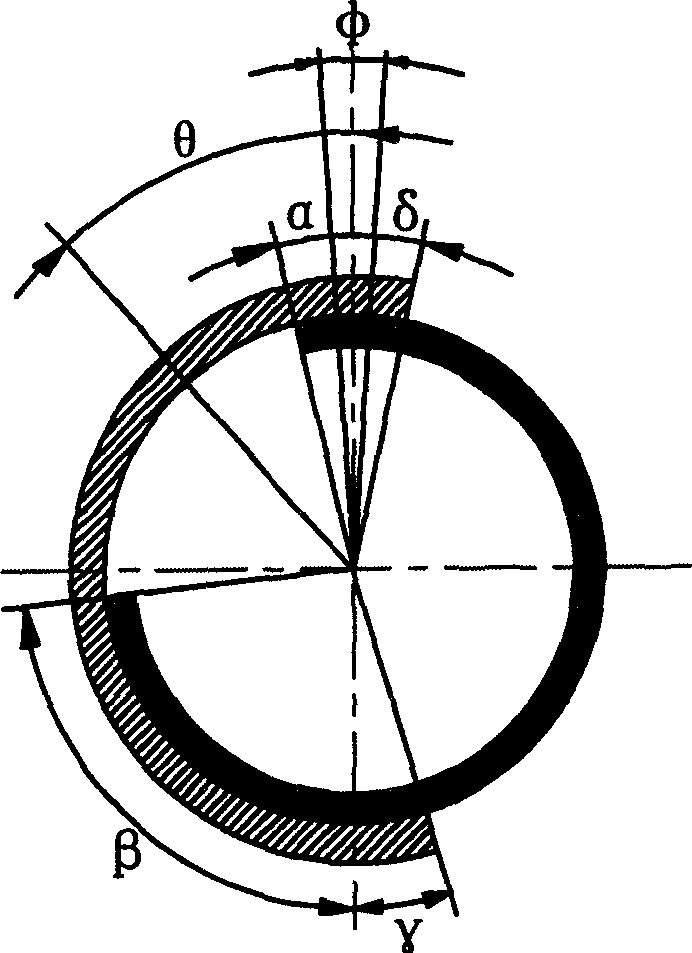

Fuel oil uniform mixing and burning system of double air ports diesel engine

InactiveCN101451463AImprove performanceReduce angleInternal combustion piston enginesFuel injection apparatusCombustion systemCombustion chamber

The present invention relates to a fuel equipartition mixture and combustion device design proposal of two valve diesel. A fuel injector set on the cylinder cap and an inlet channel; a burning compartment is below the fuel injector and inlet channel; the inlet channel is eddy flow type inlet channel; a drop pit shape shrunk burning compartment in the shape of letter W is set above the valve; head section of the fuel injector stretches out of the bottom of the cylinder cap and against the burning compartment. Parameter design of cylinder cap, fuel injector and burning compartment make fuel and air adequate distribution in certain rules on axial and circumferential direction within effective combustion space, and realize oil gas mixing design of equal excess air factor within effective combustion space. Under effect of high jet pressure and air-intake transverse currents of fuel injection system, oil gas inside the cylinder mixes uniformly, velocity of combustion quicker, duration short, oil spout can be postponed, and high-efficiency quick burning of low discharge can be realized. Engine synthetic performance can be optimized through the invention, and engine power can be improved while nocuousness discharged object can be reduced.

Owner:JIANGSU UNIV

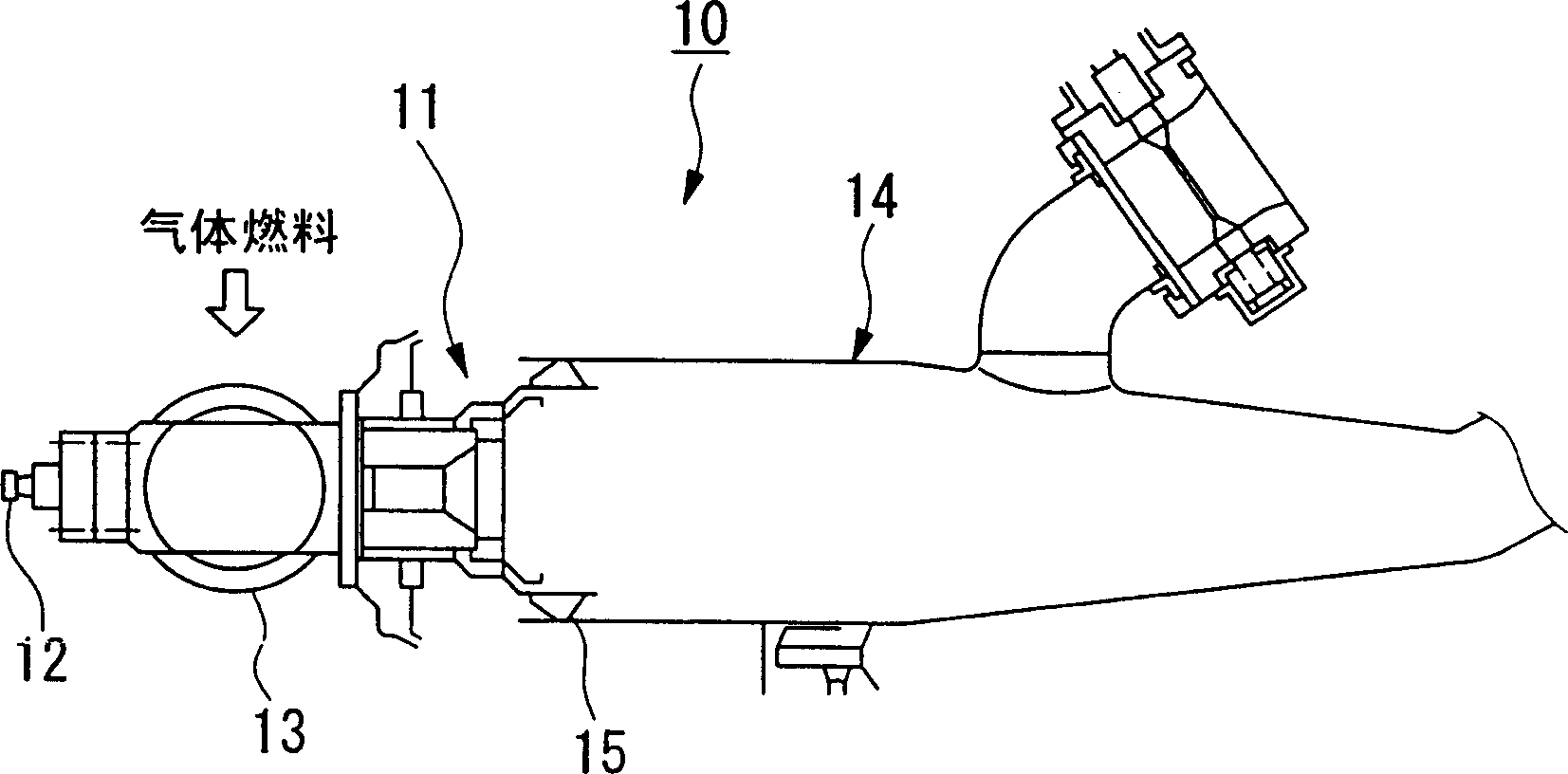

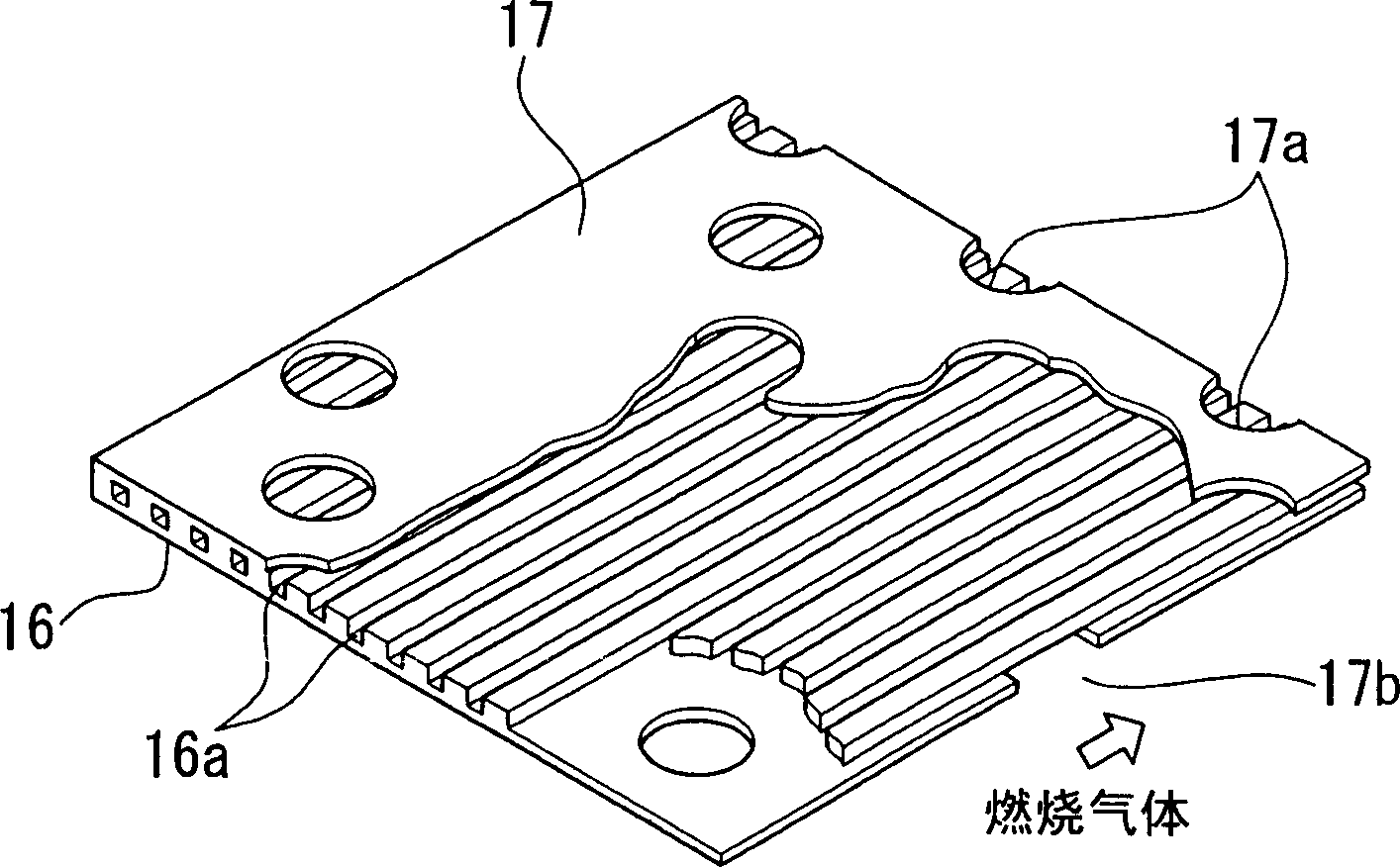

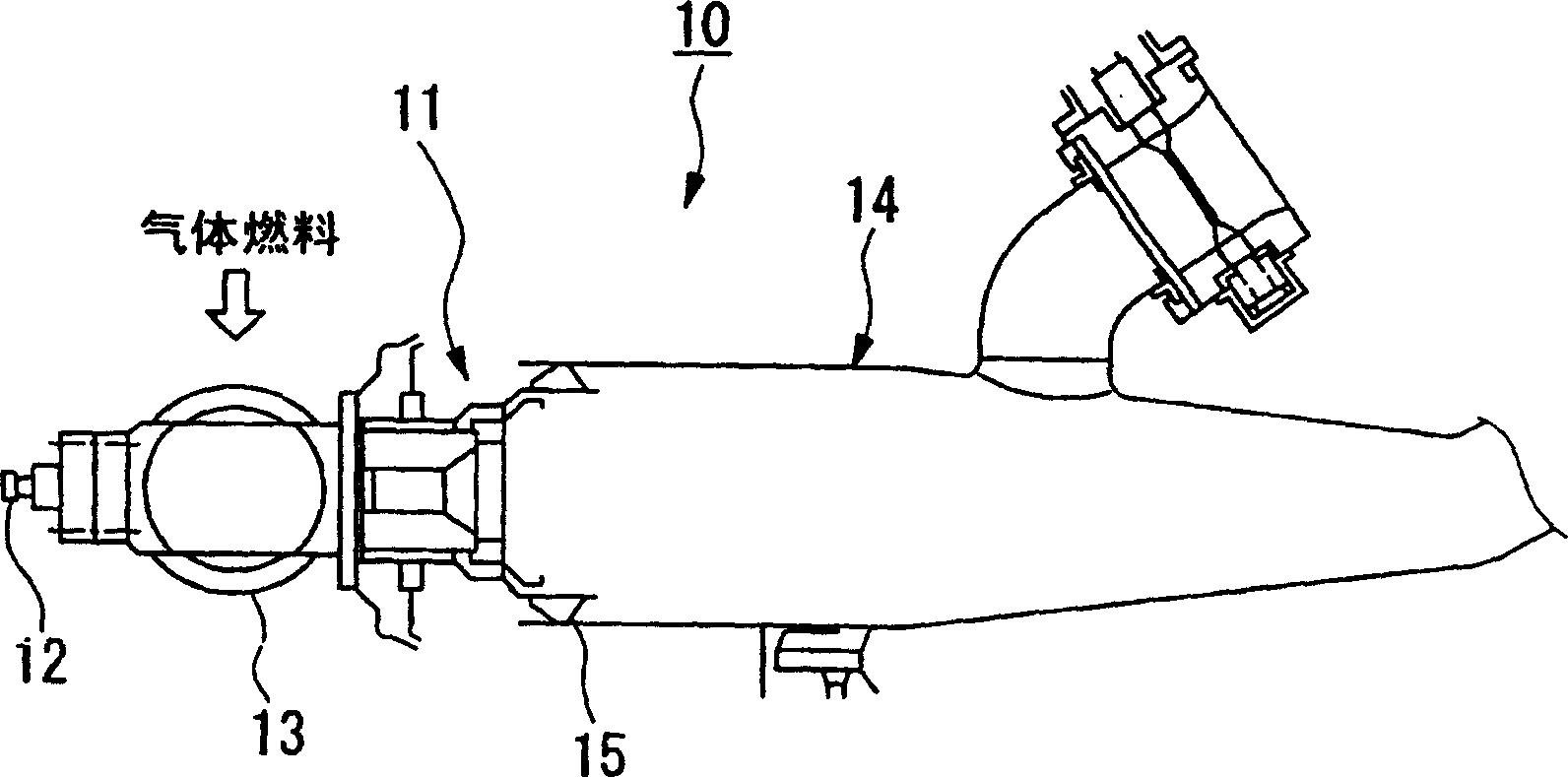

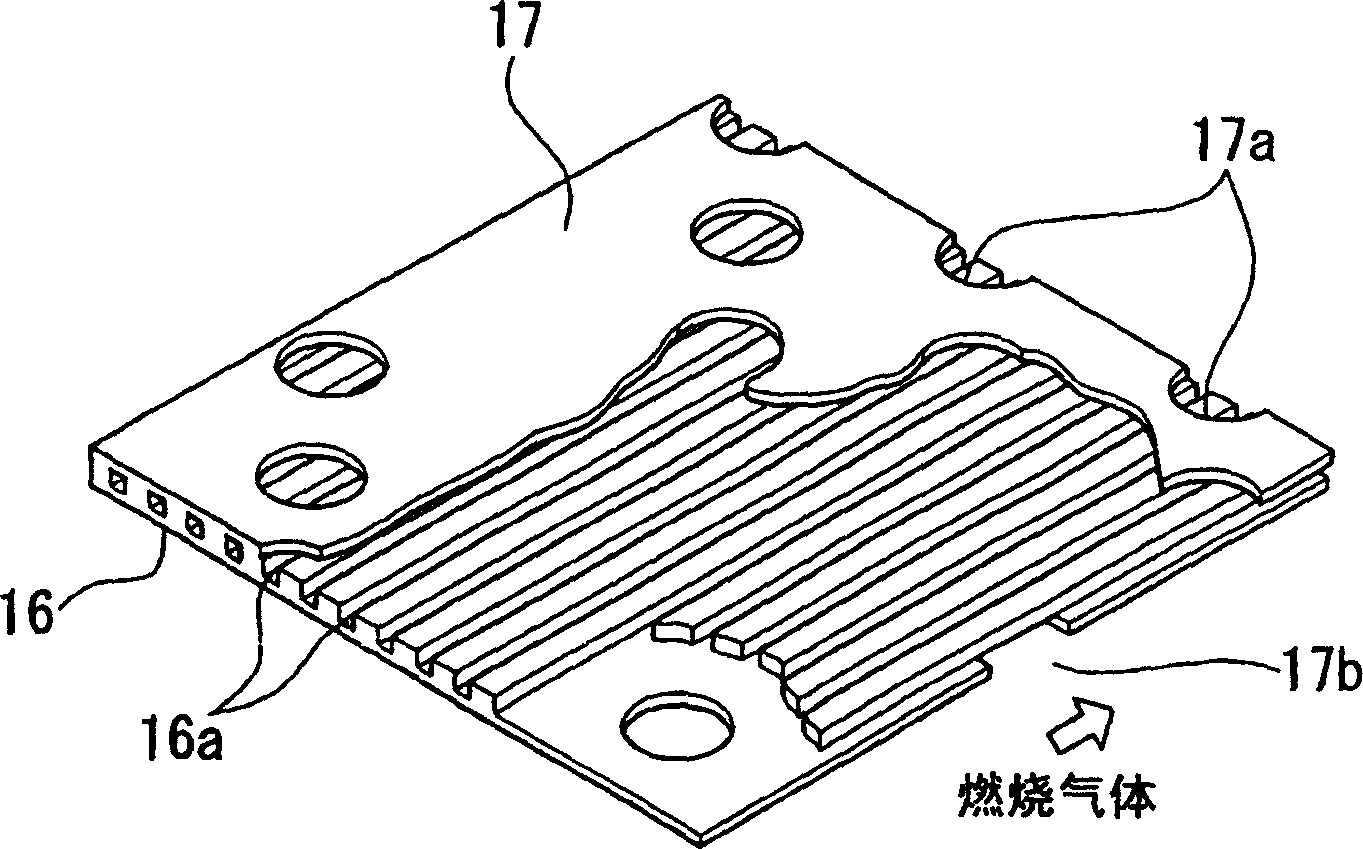

Gas turbine and its combustion chamber.

InactiveCN1415897AAchieve combustionConvenient cooling operationContinuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

A combustor section (14) is disposed downstream of a nozzle section (11). The combustor section (14) extends from a downstream end of the nozzle section (11) to an entrance of a gas turbine and supplies a combustio n gas which is generated by combusting a premixed gas to a gas turbine. The combustor section (14) is formed by an inner tube and a tail tube unitarily. The combustor (10) is provided with a wall cooling apparatus for cooling a wall surface of the combustor (10). On the inner wall of the combustor section (14), grooves are formed. An entrance for introducing an air for cooling action is disposed on the outer wall of the combustor section (14). The introduced air performs a film cooling and connective cooling in a combined manner. By doing this, the temperature of the combustion gas may be high, and a highly efficient gas turbine is realized.

Owner:MITSUBISHI HEAVY IND LTD

Any-tooth-difference movable type high rotation speed internal combustion engine

InactiveCN103047008ACompact structureReduce axial sizeGearingMachines/enginesThrough transmissionElectric generator

The invention provides an any-tooth-difference movable type high rotation speed internal combustion engine and relates to the field of combustion gas power. Eight cylinder are annularly and evenly distributed around an outward-protruding inner gear to enable the outward-protruding inner gear to be subjected to zero stress, cylinder pistons directly act on the outward-protruding inner gear through pushing rods, and power is transferred to an output shaft connected with a multiple-phase shock wave cam key through transmission of the outward-protruding inner gear and a multiple-phase cam type moving oscillating teeth. A connecting rod and a crankshaft in a traditional internal combustion engine are omitted, an outward-protruding inner multiple-phase cam type moving transmission mechanism has the advantages of being free of eccentric mass and having inertia force and working load self balance, the rotating speed of the output shaft depends on the transmission ratio of the oscillating teeth, if an oscillating tooth frame is fixed, a multiple-phase shock wave cam performs high-speed output, and the high rotation speed internal combustion engine can be widely applied to the field of machines needing high rotation speed, such as a helicopter engine, a small power generator and the like. When the output rotation speed is fixed, emission of harmful gas can be reduced. The any-tooth-difference movable type high rotation speed internal combustion engine is simple and compact in structure, small in axial size, self-balancing in stress and stable in operation.

Owner:SICHUAN UNIV

Two-phase shock wave movable type high-rotation speed internal combustion engine

InactiveCN102900524AReduce axial sizeCompact structureMachines/enginesExternal combustion engineInternal combustion engine

The invention discloses a two-phase shock wave movable type high-rotation speed internal combustion engine, relates to the field of fuel gas power and provides a novel internal combustion engine. According to the internal combustion engine, eight cylinders are symmetrically arranged at the periphery of an externally raised inner gear ring uniformly, so that resultant force applied to the externally raised inner gear ring is zero; pistons of the cylinders directly act on the externally raised inner gear ring through push rods; and power is transmitted by the externally raised inner gear ring through a two-phase shock wave movable teeth transmission mechanism to an output shaft which is in keyed connection with a two-phase shock wave device. By the internal combustion engine, connection rods and crank shafts in the conventional internal combustion engine are eliminated, so that an externally raised inner two-phase shock wave movable transmission mechanism does not have eccentric mass, and the internal combustion engine has the characteristics that inertia force and working load are self-balanced; the rotation speed of the output shaft depends on a movable teeth transmission ratio; if movable teeth frames are fixed, the two-phase shock wave device outputs power at high speed; the internal combustion engine can be widely applied to field such as helicopter engines and small engines in which high rotation speed is required; when the output rotation speed is fixed, emission of harmful gas can be reduced; and besides, the internal combustion engine is simple and compact in structure, has a small axial size and stably runs, and stress is self-balanced.

Owner:SICHUAN UNIV

Microemulsion fuel prepared from quantization carbon material, and preparation and apparatus thereof

InactiveCN101469278AImprove oil qualityImprove and improve oil qualityRefining by water treatmentWater/sewage treatment by sorptionFuel oilWaste oil

The invention relates to a microemulsion fuel oil, which is prepared from the following raw materials by weight proportion: 1 to 99 portions of crude oil, waste oil, animal oil or vegetable oil; 1 to 99 proportions of ion activated water; 0.01 to 1 portion of quantized carbon material liquid; and a small quantity of metal salt with catalysis, wherein the quantized carbon material liquid is the quantized carbon material liquid concerned by a Chinese patent application of which the application number is 200810105108.1. The microemulsion fuel oil adopts the activated water treated by the quantized carbon material liquid to replace common water, wherein the quantized carbon material is treated by a special process and is a super-amphiphilic binary synergetic micro interface material, and hydroxide radical is discovered after the surface is modified in the electrochemical process for preparing the material so that the quantized carbon material has combustion-supporting effect. The microemulsion fuel oil can remarkably enhance and improve the combustion condition so as to produce clean fuel oil which can be burnt more perfect with more stable quality and evener dispersion and mixing.

Owner:北京三昌宇恒科技发展有限公司

Optional tooth difference swing type high-rotation-speed internal-combustion engine

An optional tooth difference swing type high-rotation-speed internal-combustion engine relates to the field of gas power. The tooth difference swing type high-rotation-speed internal-combustion engine is characterized in that eight air cylinders are annularly evenly distributed on the periphery of a protruding inner gear ring to allow resultant force borne by the inner gear ring to be zero. An air cylinder piston directly acts on the protruding inner gear ring through a push rod. Power is transmitted by protruding inner gear ring to an output shaft connected with a multi-phase shock wave wheel key through transmission of a multi-phase cam swing movable tooth. A connecting rod and a crankshaft in traditional internal-combustion engines are omitted, and the protruding inner multi-phase cam swing transmission mechanism has no eccentric weight, and has the advantages that self-balancing of inertia force and work load. Rotation speed of the output shafts depends on transmission ratio of movable tooth transmission. If a movable tooth frame is fixed, high-speed output of the multi-phase shock wave wheel is achieved. The internal-combustion engine is widely applicable to fields, which need high rotation speed, such as helicopter engines and small power generators. When rotation speed is fixed, emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, low in axial size, self-balancing in stress, and stable in operation.

Owner:SICHUAN UNIV

Gas turbine and its combustion chamber.

InactiveCN1187556CConvenient cooling operationComprehensive responseContinuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

A combustor section (14) is disposed downstream of a nozzle section (11). The combustor section (14) extends from a downstream end of the nozzle section (11) to an entrance of a gas turbine and supplies a combustio n gas which is generated by combusting a premixed gas to a gas turbine. The combustor section (14) is formed by an inner tube and a tail tube unitarily. The combustor (10) is provided with a wall cooling apparatus for cooling a wall surface of the combustor (10). On the inner wall of the combustor section (14), grooves are formed. An entrance for introducing an air for cooling action is disposed on the outer wall of the combustor section (14). The introduced air performs a film cooling and connective cooling in a combined manner. By doing this, the temperature of the combustion gas may be high, and a highly efficient gas turbine is realized.

Owner:MITSUBISHI HEAVY IND LTD

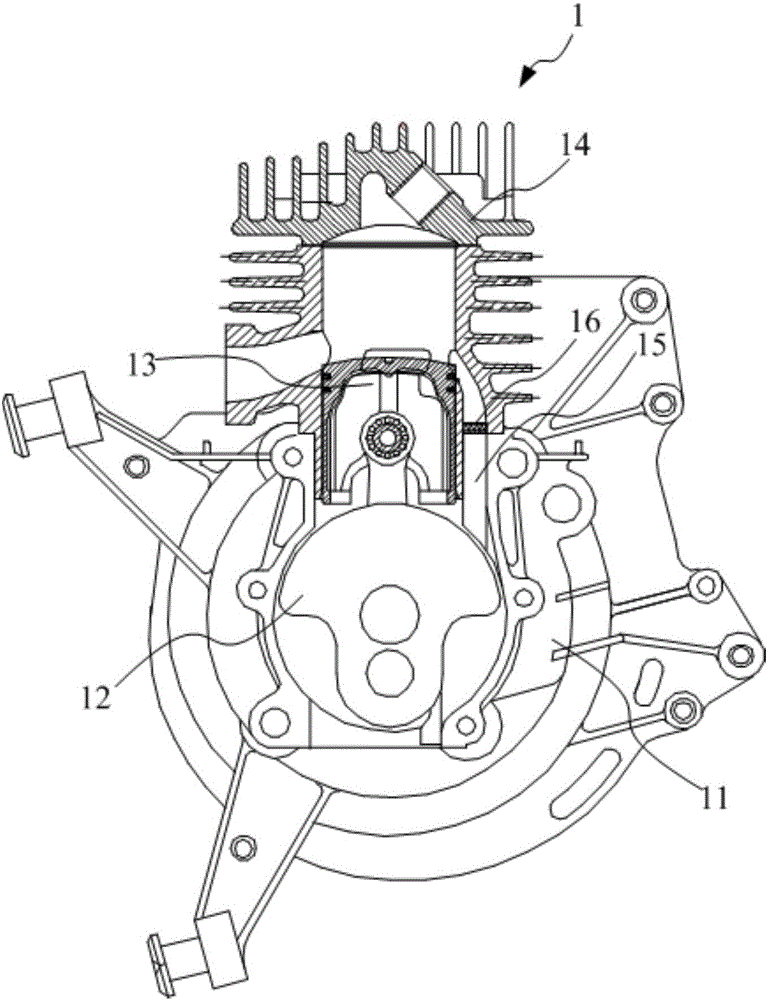

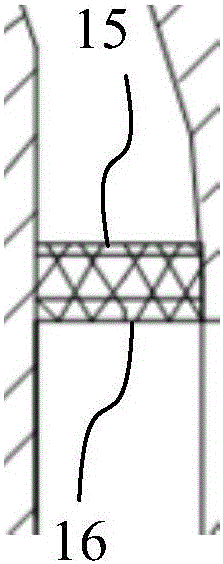

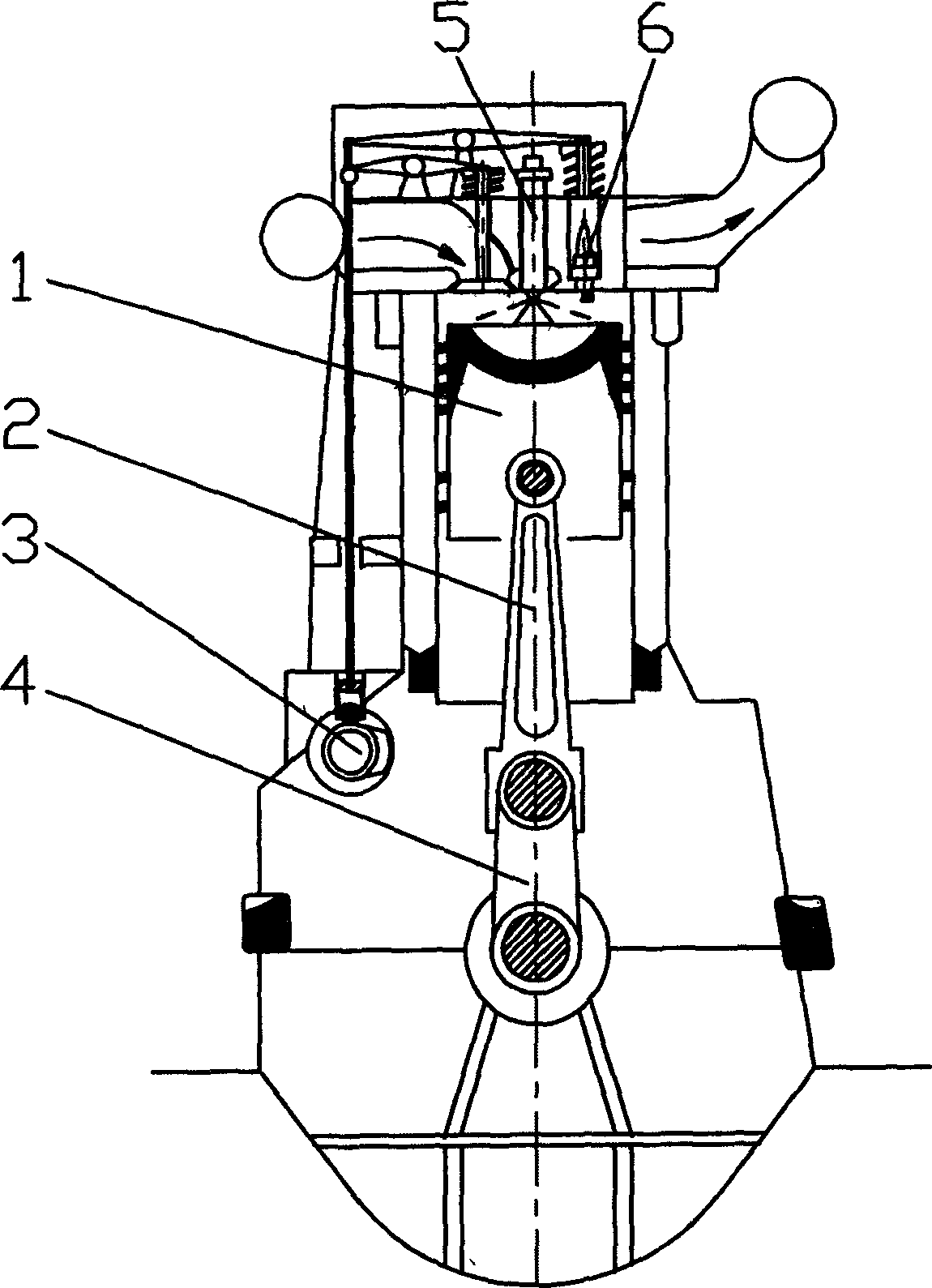

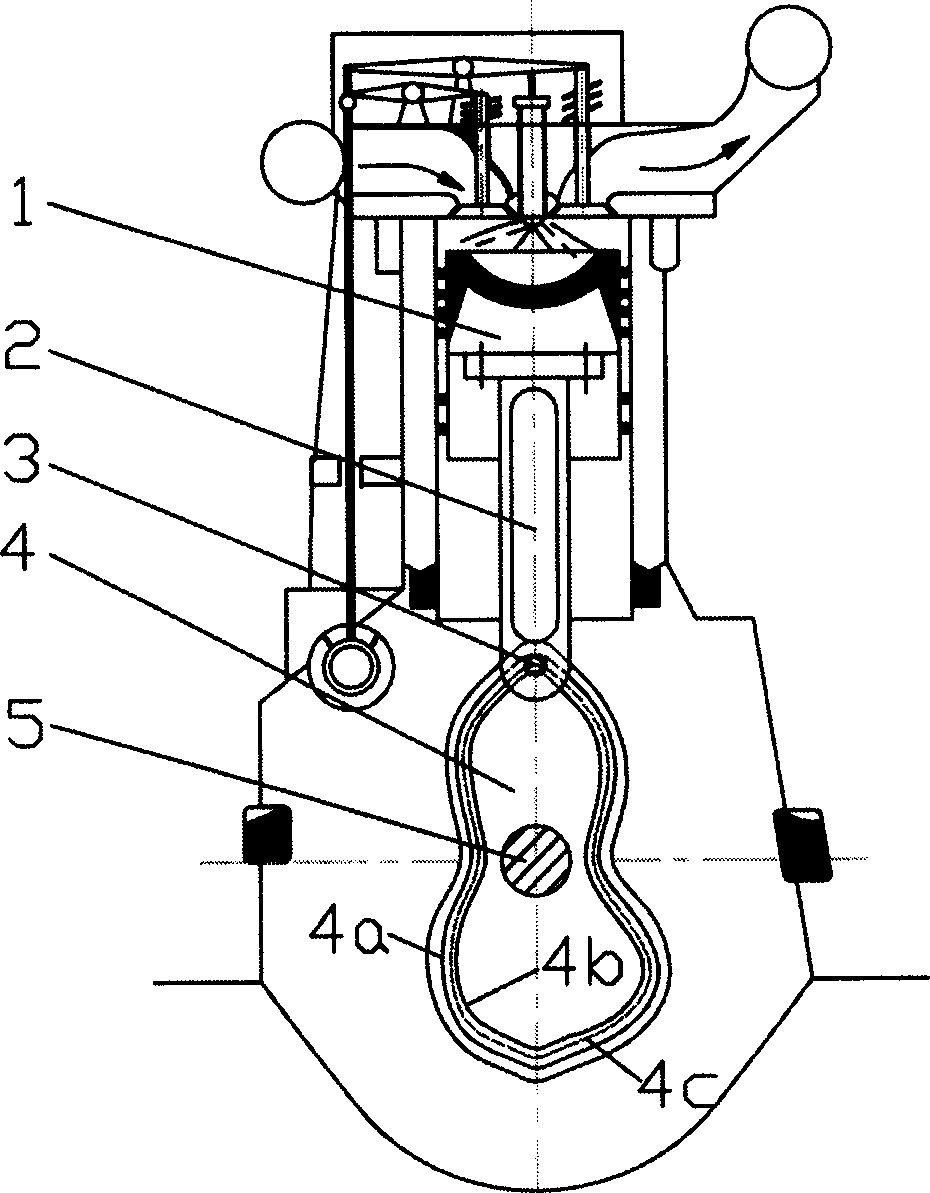

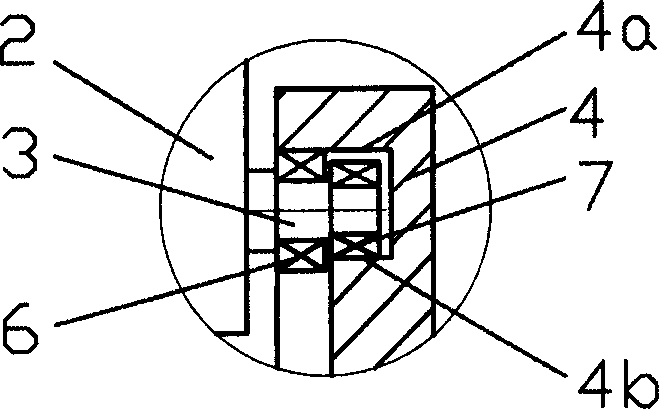

Lubricating oil separating device of two-stroke gasoline engine

InactiveCN105019981APerfect combustionReduce high emissionsMachines/enginesCrankcase ventillationCombustion chamberGasoline

The invention provides a lubricating oil separating device of a two-stroke gasoline engine. The lubricating oil separating device comprises a crankshaft box body, a crankshaft, a piston, an air cylinder, an air cylinder cover, an air inlet, an air ventilating hole, an air outlet and an air scavenging duct, wherein the crankshaft is mounted and arranged in the crankshaft box body, the piston is positioned at the upper part of the crankshaft box body, the air cylinder cover covers the air cylinder, the air inlet, the air ventilating hole and the air outlet are formed in the air cylinder, the air scavenging duct is formed in the air cylinder and connected with the crankshaft box body in a penetrating through manner, and a filter for filtering lubricating oil in flammable mixed gas is mounted and arranged at a position of the air scavenging duct between the air inlet and the air ventilating hole; the filter comprises S-shaped filtering screens, and the filtering screens can be multilayer. When the flammable mixed gas flows through the filter, lubricating oil particles adhere to the filtering screens of the filter, so that the lubricating oil particles in the flammable mixed gas are filtered, and the flammable mixed gas entering a burning chamber contains a mixture of gasoline and air and little or zero lubricating oil; through the adoption of the lubricating oil separating device disclosed by the invention, the gasoline can be fully burnt, and the problems of high emission and heavy pollution because engine oil is burnt are solved.

Owner:SHANGHAI KUNFU ENTERPRISE GRP +2

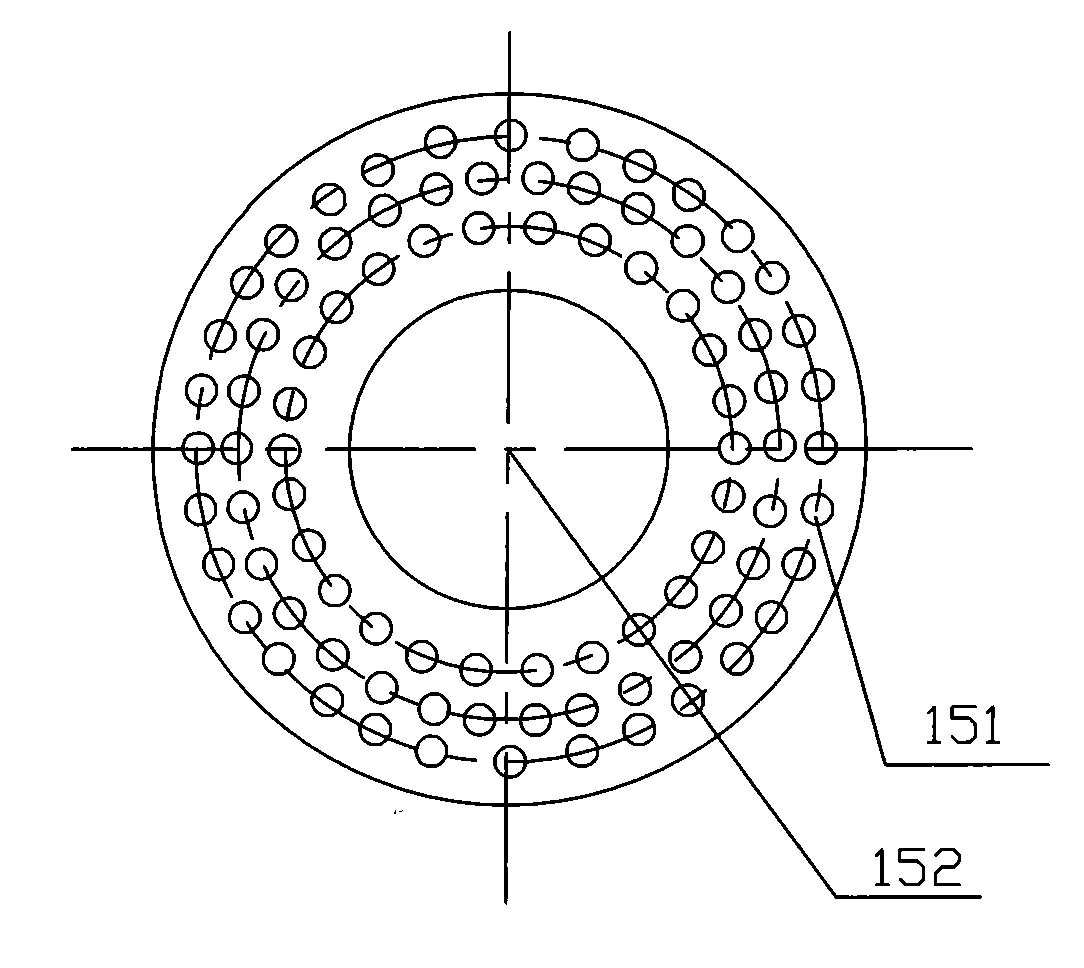

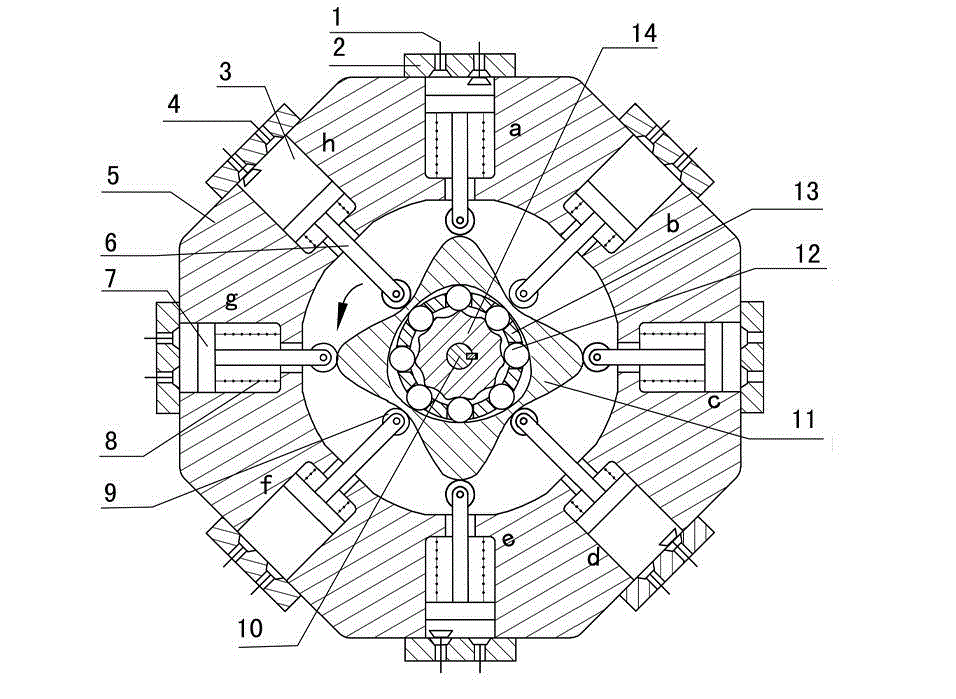

Outer convex cam roller transmission internal combustion engine with any inner tooth difference

InactiveCN103147856ACompact structureReduce axial sizeValve drivesMachines/enginesLow speedExternal combustion engine

The invention discloses an outer convex cam roller transmission internal combustion engine with any inner tooth difference, relates to the field of gas power and belongs to a multi-cylinder engine. The invention provides a novel internal combustion engine; eight cylinders are annularly and symmetrically distributed at the periphery of an outer convex multiphase inner cam evenly, so that the force of the outer convex multiphase inner cam is zero; pistons of the cylinders directly act on the outer convex multiphase inner cam by push rods; and power is transmitted to an output shaft which is connected with a center wheel in a key way by the outer convex multiphase inner cam through cam roller oscillating teeth with any inner tooth-difference. The internal combustion engine omits connecting rods and crankshafts of the traditional internal combustion engine; and an outer convex multiphase inner cam roller transmission mechanism does not have eccentric mass and has the advantages of inertia force and working load self-balancing. The rotating speed of the output shaft depends on the transmission ratio of oscillating tooth transmission; if an oscillating tooth carrier is fixed, the center wheel is output in large torque and at the lower speed; and the outer convex cam roller transmission internal combustion engine with any inner tooth difference can be widely used for the fields of engineering and military in need of the high power, such as engineering machinery, armored cars and the like. The internal combustion engine has the advantages of simplicity and compactness in structure, small axial dimension, self-balancing in stress and stability in operation.

Owner:SICHUAN UNIV

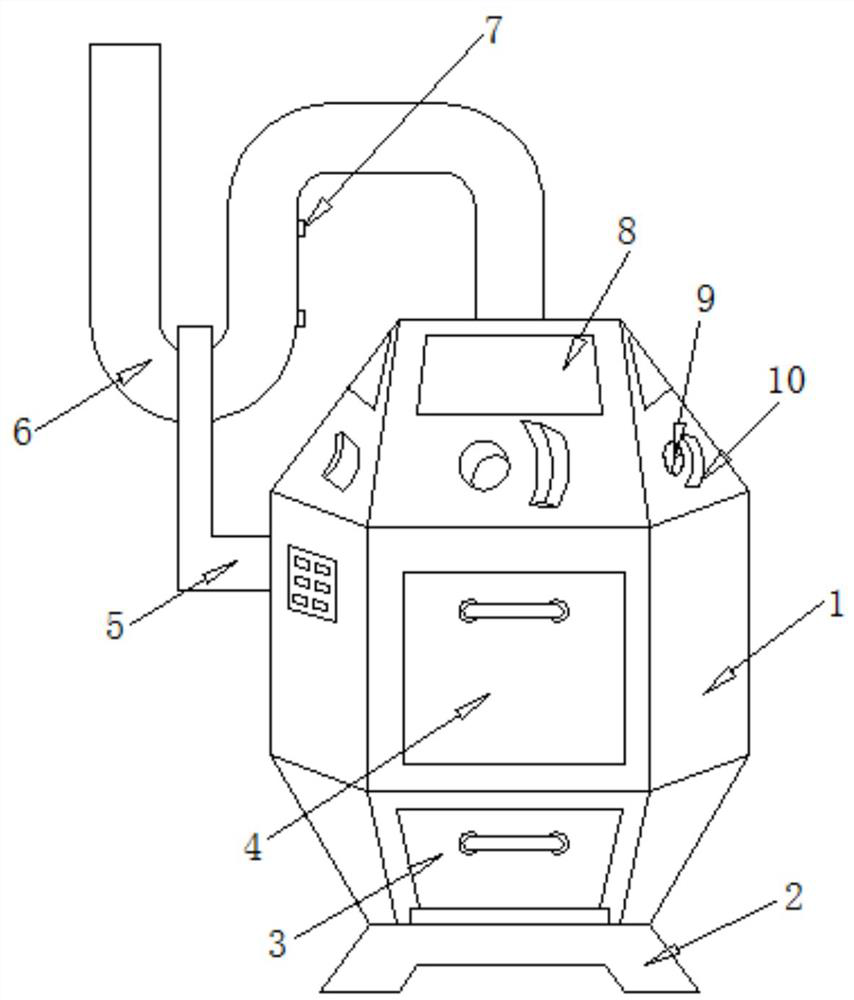

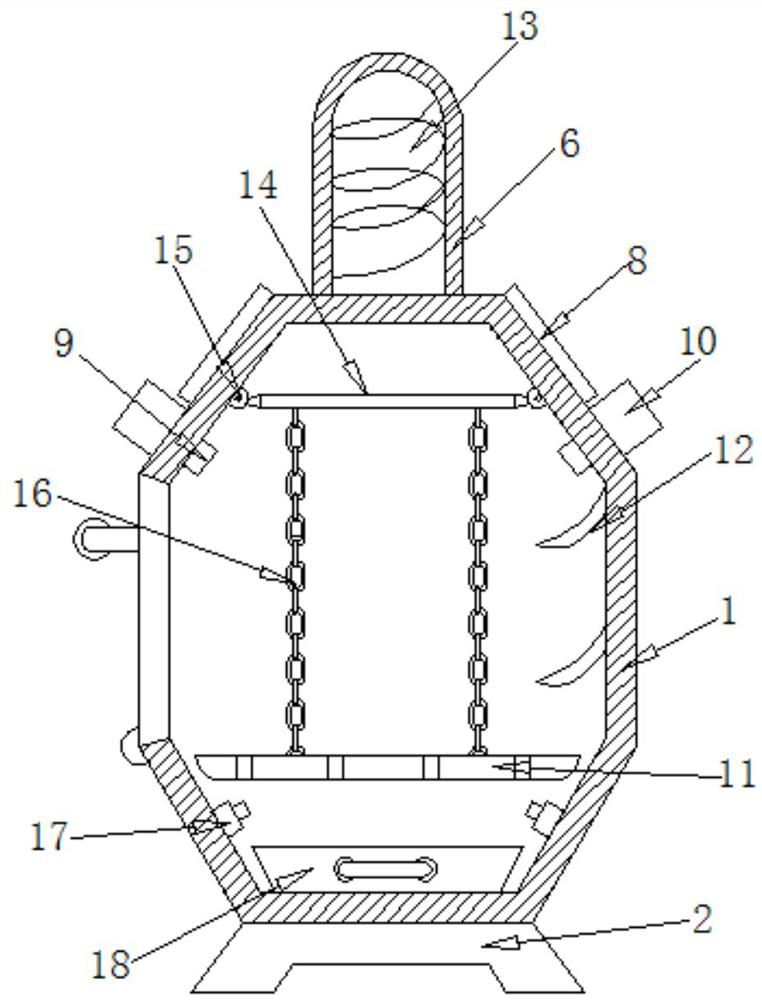

An energy-saving and environment-friendly domestic waste incinerator

ActiveCN109373329BIncrease the areaIncrease oxygen contentIncinerator apparatusEnvironmental engineeringSolar battery

The invention discloses an energy-saving and environment-friendly domestic garbage incinerator which comprises an incinerator body. The incinerator body is of a hexagonal structure, and the inner walls of the two ends of the incinerator body are inclined inwards. A base is welded to the bottom end of the incinerator body, and a waste discharging port is formed in the bottom of the outer wall of one side of the incinerator body. A feeding port is formed in the outer wall of one side of the incinerator body. Solar cell panels which are distributed at equal intervals are fixed to the top of the outer wall of one side of the incinerator body through bolts. Air inlets which are distributed at equal intervals are formed in the outer wall of one side of the incinerator body. By means of the energy-saving and environment-friendly garbage incinerator, airflow outside the device is converged to form air through arc plates, air force passes through the inclined air inlets to form wind volumes under the help of screw blades, the effective combustion area and the oxygen content of garbage are increased, dust particles in waste gas are ionized after electric conduction of a big-end-up conical metal sleeve is conducted, the dust particles fall layer by layer after dropping, and the environment-friendly capability of the device is improved again.

Owner:江苏创亚普光热电产业技术研究院有限公司

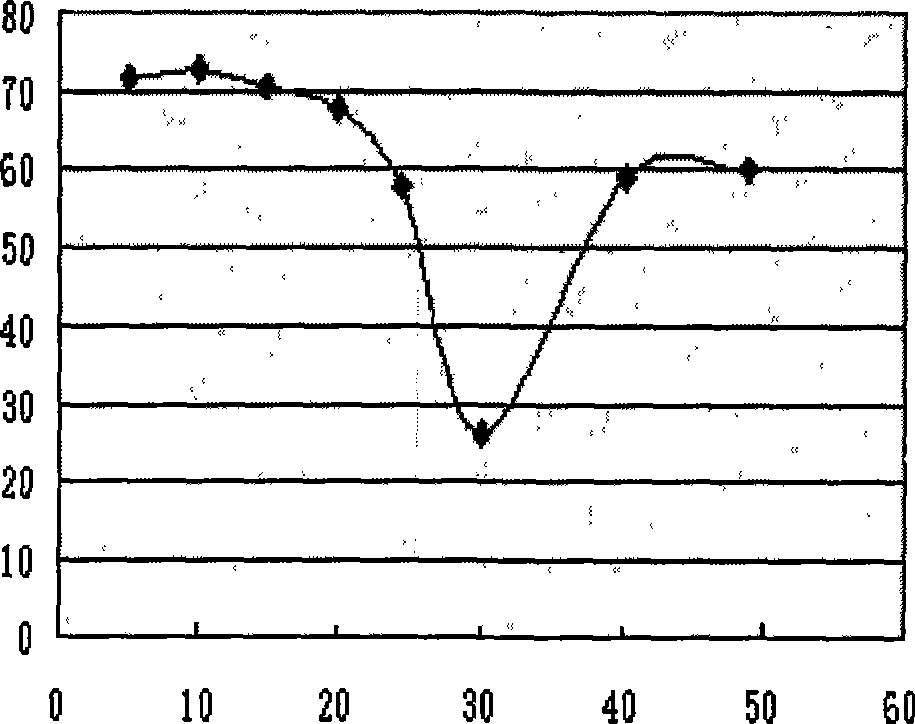

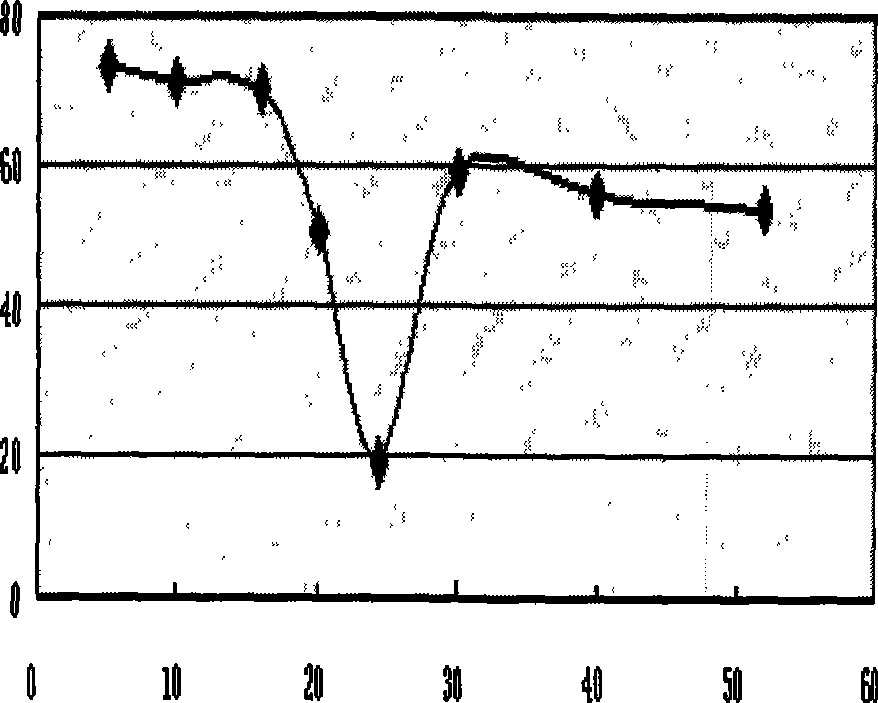

Premixed combustion system of diesel engine

InactiveCN1657749AStable and reliable fireRealize the purpose of efficient and clean combustionInternal combustion piston enginesThermal energyCombustion system

A diesel engine pre-mixing burning system has larger lagging angle of air feeding and geometric advancing angle of oil feeding, it has remarkably decreased compression ratio, loss of pumping air and the temperature of air compressed, prolonged combustion lagging period so that the burning point is controlled near the newtonian focus of compression stroke, in addition to the spark plug being lightened, the diesel engine is ensured to lighted in low compression ratio ; besides, the high expansion ratio has made full use of competence of apply work of air cylinder combustion gas. The pre-mixing method makes burning more complete and perfect, has high energy utilization ratio, decreases the highest pressure as well as highest temperature, plongs its service life and realizes the goal of highly effective cleaning of diesel engine burning.

Owner:DALIAN UNIV OF TECH

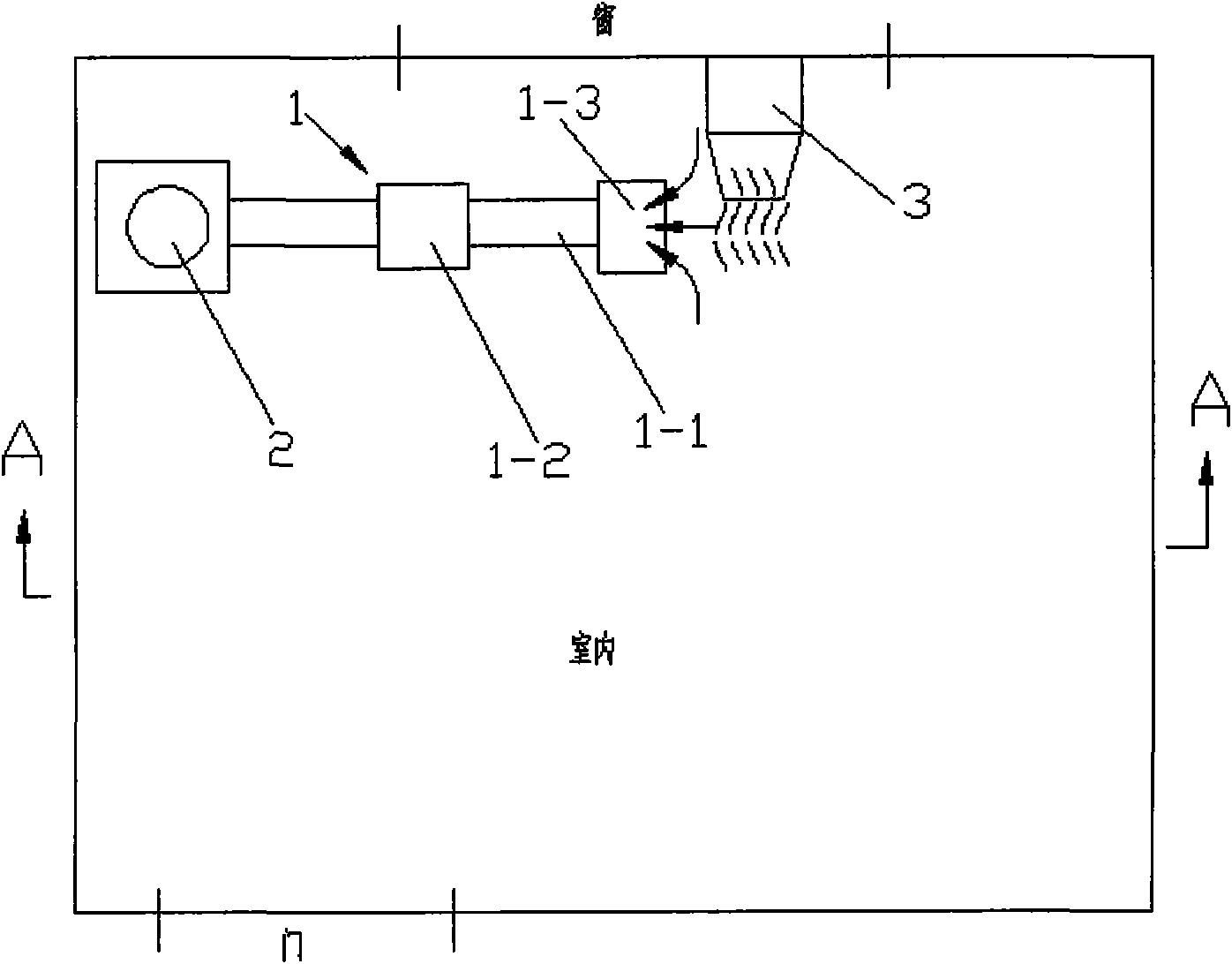

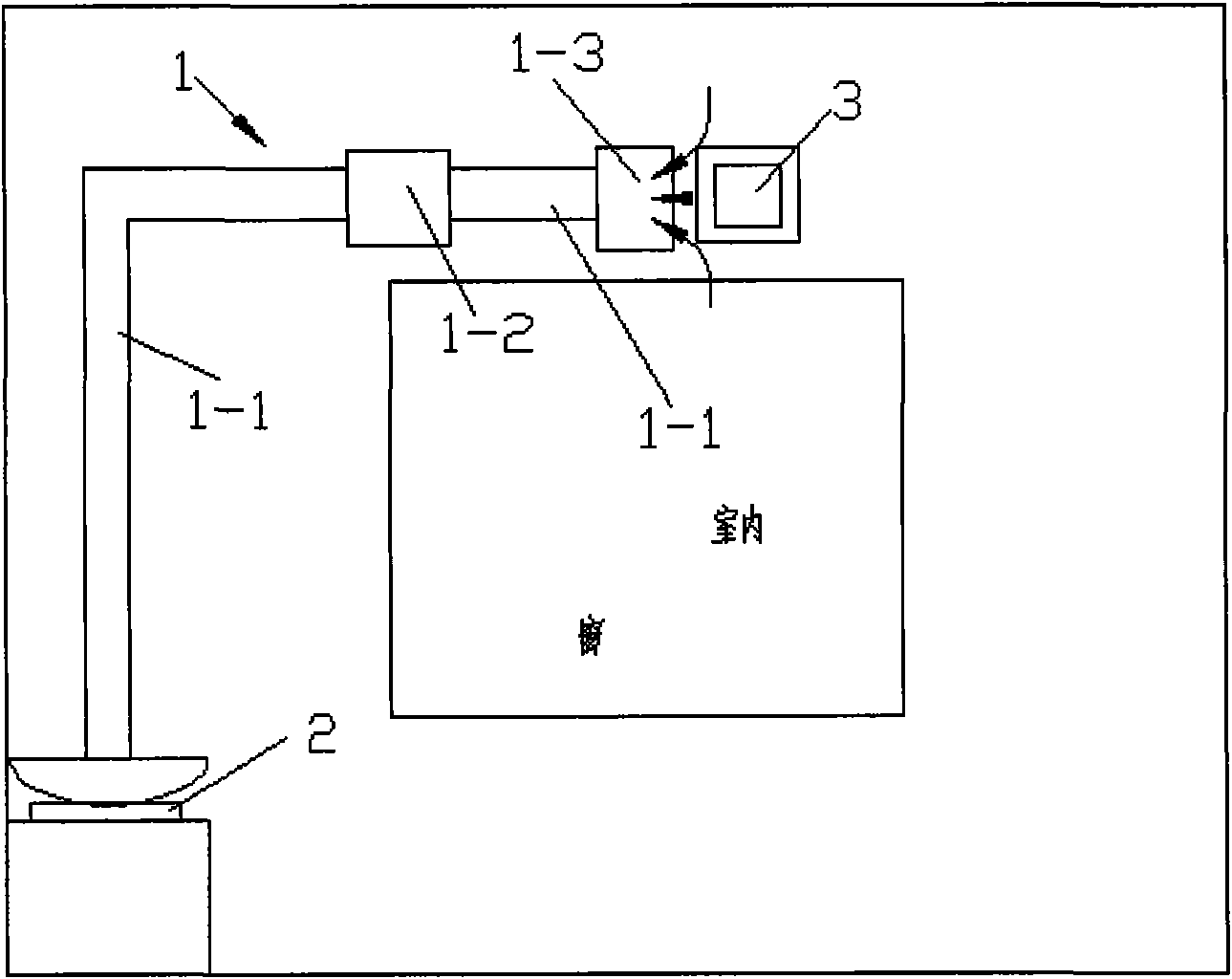

Greenhouse gas treatment method

InactiveCN102121701ASolve the difficult problem of the rapid increase of the global warming effectIncrease profitDispersed particle separationIncinerator apparatusPower stationCombustor

The invention relates to a method for treating greenhouse gases produced by the industries of industry, dining halls, power stations and the like. The treatment method comprises that: the greenhouse gases are recycled into a gas burner (2) by a recycling device (1) for burning treatment. By the treatment method, the problem in the prior art that the greenhouse gases are incompletely treated and finally emitted to the air to pollute the environment and cause the rapid intensification of global warming is solved; combination simplicity and simplicity and convenience of mounting are achieved; when the method is used, conventional facilities are not required to be replaced, so the method is low in cost and convenient to popularize; and when the method is used, the recycled greenhouse gases are utilized as combustion improvers, so more energy can be saved.

Owner:伍镜清

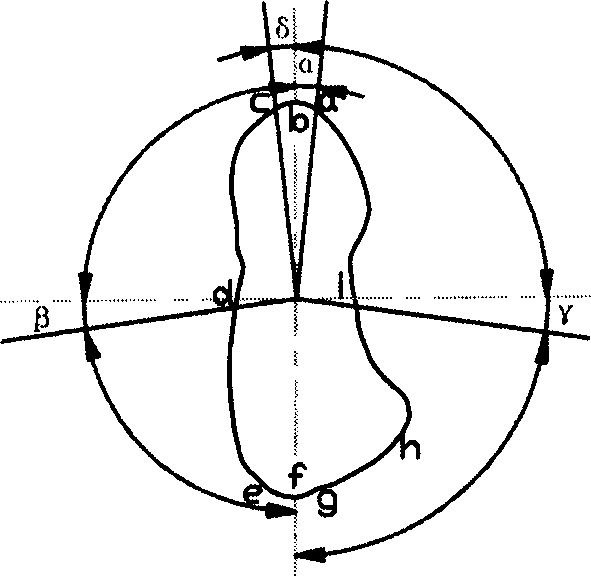

Cam driving type four stroke engine

InactiveCN1651733AImprove powerImprove economyReciprocating piston enginesExternal combustion engineFour-stroke engine

The present invention relates to a cam-operated four-stroke engine, belonging to the field of structure and combustion technology of reciprocating internal combustion engine. Said engine adopts an symmetrical cam to transfer the work applied by piston to the main shaft, and the mani shaft is rotated for every one circle, the piston can apply work once, and the characteristics of motion of said piston is completely dependent on the moulded line of said asymmetrical be easily controlled. Said can drive structure not only is applicable to diesel engine and carburetor engine, but also is applicable to engine using various fuels.

Owner:DALIAN UNIV OF TECH

Three-in-one garbage incineration method

The invention discloses a three-in-one garbage incineration method. The three-in-one garbage incineration method is characterized by being performed according to the following technological process: (a) pulverized coals are doped in garbage to be mixed for future use; and the doping quantity is 1-5% of the garbage by weight; (b) an emulsifying agent and oil are added in water to prepare emulsifying oil; and the adding quantities of the emulsifying agent and the oil are respectively 1-5% and 30-70% of the water by weight; and (c) the garbage containing the pulverized coals is fed into a boiler hearth for burning; and the prepared emulsifying oil is sprayed into the boiler hearth for burning.

Owner:徐小芹

Cam rolling transmission internal combustion engine with external convex internal arbitrary tooth difference

The invention discloses an outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine, relating to the field of fuel gas power and belonging to a multi-cylinder internal-combustion engine. The invention provides a novel internal-combustion engine; eight cylinders are distributed on the periphery of an outer convex inner multiphase inner cam symmetrically in a ring shape, so that a resultant force of the outer convex inner multiphase inner cam is zero; each cylinder piston directly acts on the outer convex inner multiphase inner cam through a push rod; and power is transmitted to an output shaft connected with a central wheel key by the outer convex inner multiphase inner cam through arbitrary gear difference inner cam rolling moving movable gear transmission. With the adoption of the internal-combustion engine, a connecting rod and a crank shaft in the traditional internal-combustion engine are saved; an outer convex multiphase inner cam rolling moving transmission mechanism has the characteristics of having no eccentric mass, and having an inertia force and working load self-balancing; the rotating speed of the output shaft depends on transmission ratio of movable gear transmission; when a movable gear frame is fixed, output by a central wheel is in low speed and large torque; and the internal-combustion engine can be widely applied to the fields of high-power engineering machinery and military and the like, such as excavators and armored cars. The internal-combustion engine is simple and compact in structure, small in axial size, self-balancing in stress, and stable in rotating.

Owner:SICHUAN UNIV

Waste incineration method

The invention discloses a waste incineration method. The method is characterized by the following process flow: a, mixing pulverized coal into waste and keeping the mixture for later use, the mixing amount of the pulverized coal is 5-10% by weight of the waste; b, adding an emulsifier and oil into water to prepare emulsified oil, the adding amounts of the emulsifier and the oil are respectively 5-8% and 35-70% by weight of the water; and c, sending the waste with the pulverized coal into a boiler furnace for combustion, and spraying the prepared emulsified oil into the boiler furnace for combustion. The purpose of the invention is to provide the waste incineration method which takes the waste as a base material, collects the advantages of the oil and the pulverized coal combustion-supporting material, turns the water into treasure, reduces the total amount of coal combustion, saves energy and reduces cost.

Owner:陈留成

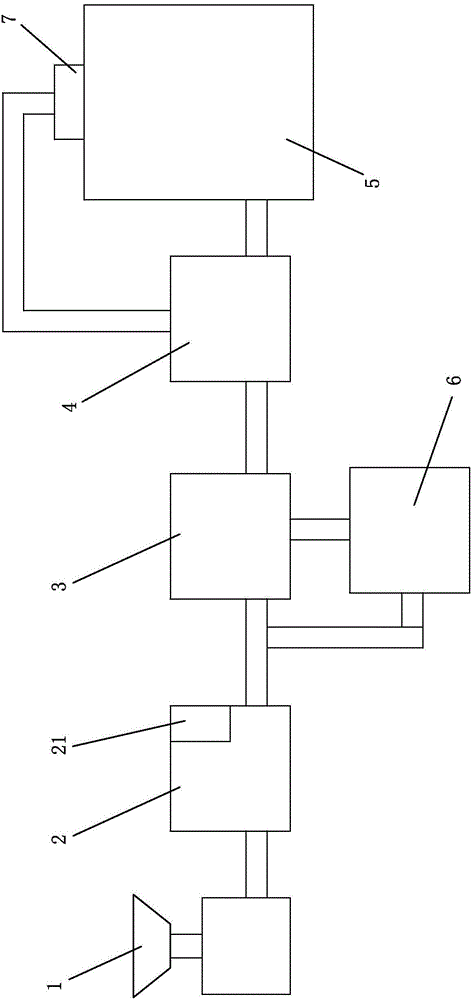

Dung fuel combustion boiler device

InactiveCN106322385AGood burning effectBest burning stateIncinerator apparatusAutomotive engineeringCombustion

The invention discloses a dung fuel combustion boiler device. The device sequentially comprises a material bin, a smashing and drying machine, an impurity removal device, a preheating device and a boiler which are connected through a conveying belt. An impurity outlet of the impurity removal device is connected with an impurity processor through a conveying belt. A discharge outlet of the impurity processor is connected to a feed inlet of the impurity removal device through a conveying belt. Dung fuel is made to be in a best combustion state through a series of processing steps, the dung fuel can be completely combusted in the boiler, and the best combustion effect is achieved.

Owner:许成荫

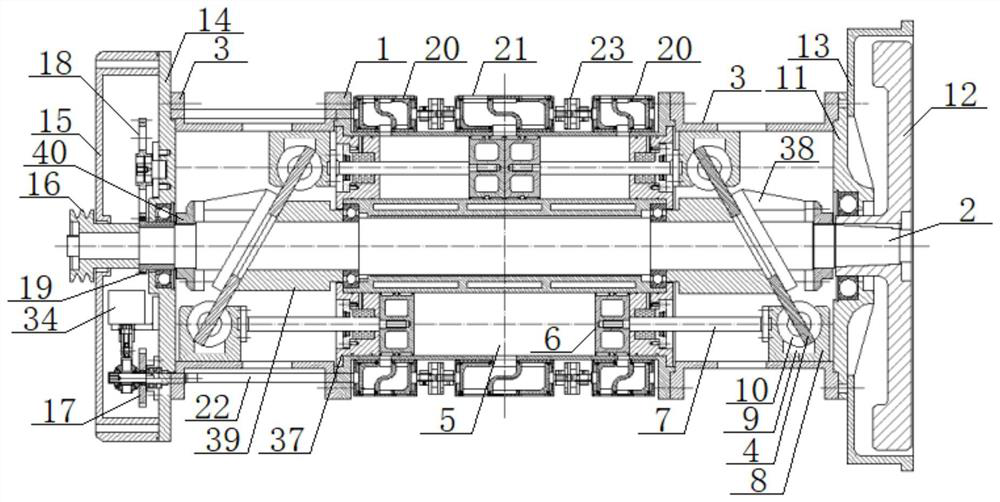

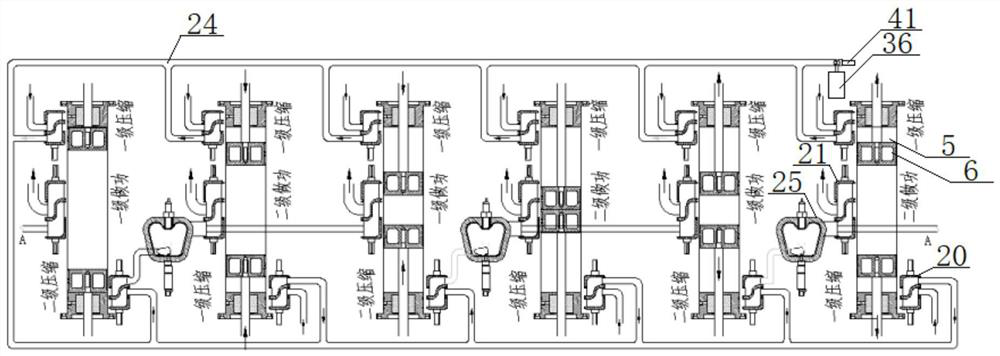

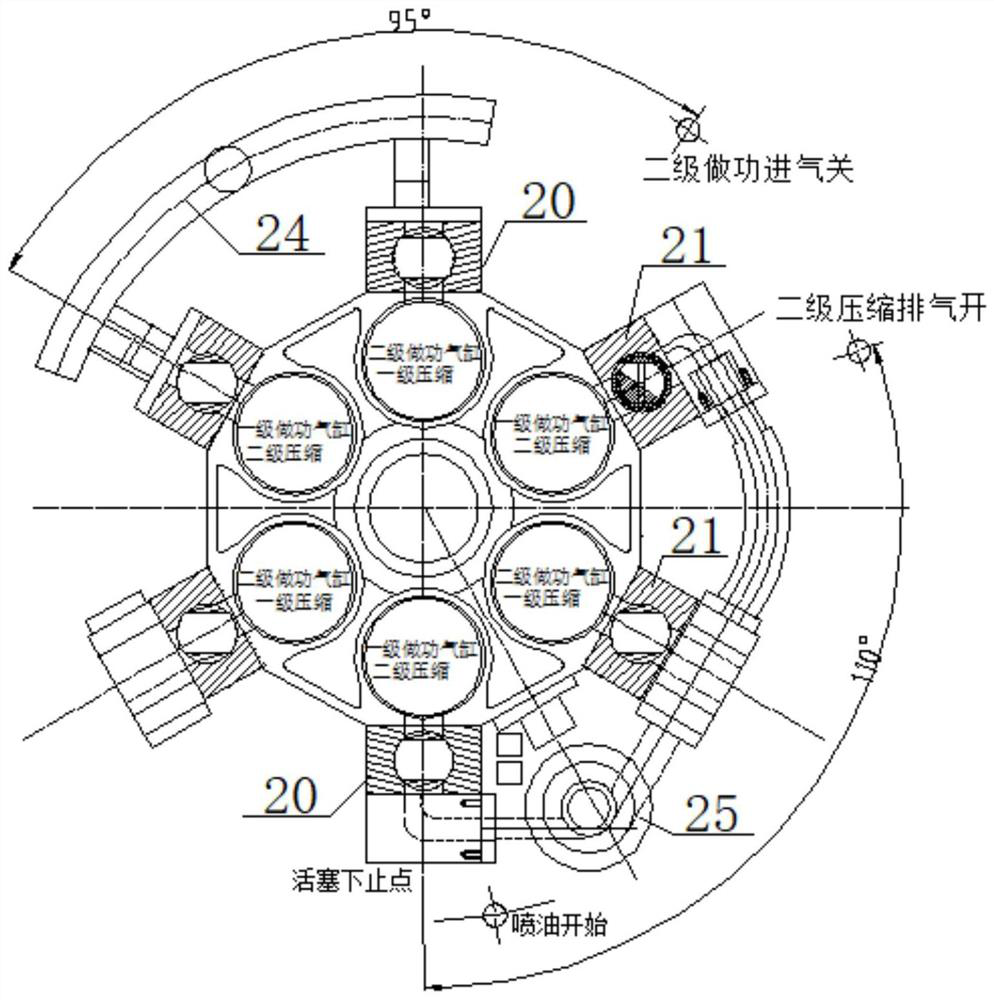

A swash-plate opposed-piston two-stroke external combustion engine

ActiveCN111810291BIncrease profitFull areaInternal combustion piston enginesPistonsExternal combustion engineEngineering

A swash plate type opposed-piston two-stroke external-combustion engine, comprising a cylinder block, a main shaft hole is opened in the middle of the cylinder block, six axially penetrating cylinders are evenly arranged on the outer periphery of the main shaft hole, and two front and rear cylinders are arranged opposite to each other in the cylinder. There are two pistons, and the front and rear ends of the cylinder are equipped with compressed air rotary valves, and the middle of the cylinder is equipped with a working rotary air valve. Among the twelve pistons, nine pistons take in air from the environment through the compressed air rotary valves and perform one-stage compression. To the gas storage branch pipe, the three pistons take in air from the gas storage branch pipe through the compressed air rotary valve and perform secondary compression to the combustion chamber. Among the six cylinders, three cylinders perform primary work, and three cylinders perform secondary work. The first-stage work cylinder is the cylinder where the piston of the second-stage compression is located, and the second-stage work cylinder is the cylinder where the two pistons before and after the first-stage compression are all performed. This design improves the utilization rate of heat energy.

Owner:刘望建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com