Dung fuel combustion boiler device

A boiler device and fuel technology, which is applied in the combustion method, combustion type, incinerator, etc., can solve the problems of incomplete combustion and uneven combustion, and achieve the best combustion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

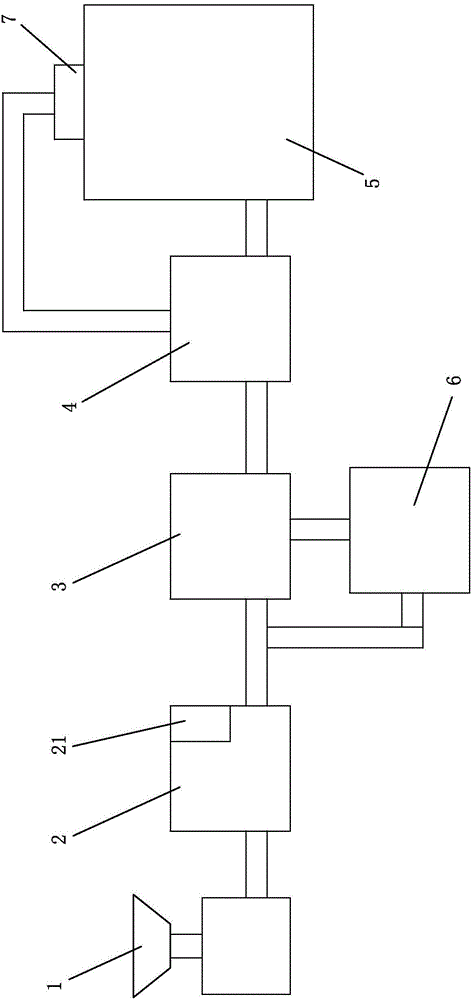

[0011] refer to figure 1 , a kind of excrement fuel burning boiler device of the present invention, comprises the material bin 1 that is connected by conveying belt, crushing dryer 2, impurity removal device 3, preheating device 4 and boiler 5 successively, the impurity removal device 3 The port is connected with an impurity processor 6 through a conveyor belt, and the discharge port of the impurity processor 6 is connected to the feed port of the impurity removal device 3 through a conveyor belt. Drying, impurity removal, preheating and other steps will be burned again, wherein the impurity removal device 3 screens the fuel with impurities to the impurity processor 6 for impurity removal, and then returns to the impurity removal device 3 for use.

[0012] As an improvement of the above-mentioned embodiment, the pulverizing dryer 2 is provided with an electrostatic adsorption device 21 to absorb dust generated during pulverization.

[0013] As a further improvement of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com