A swash-plate opposed-piston two-stroke external combustion engine

A technology of opposed piston and swash plate type, applied to internal combustion piston engines, combustion engines, engine components, etc., can solve the problem of low heat energy utilization rate, achieve the effect of improving heat energy utilization rate, reducing viscous friction, and full area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

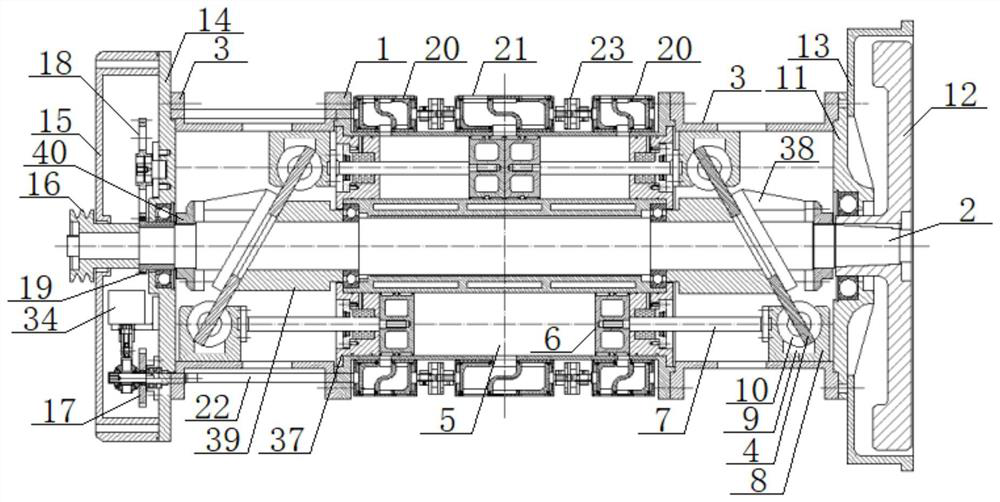

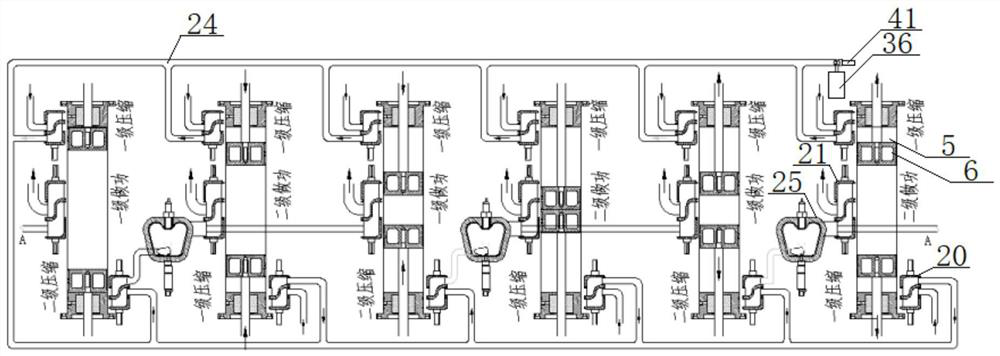

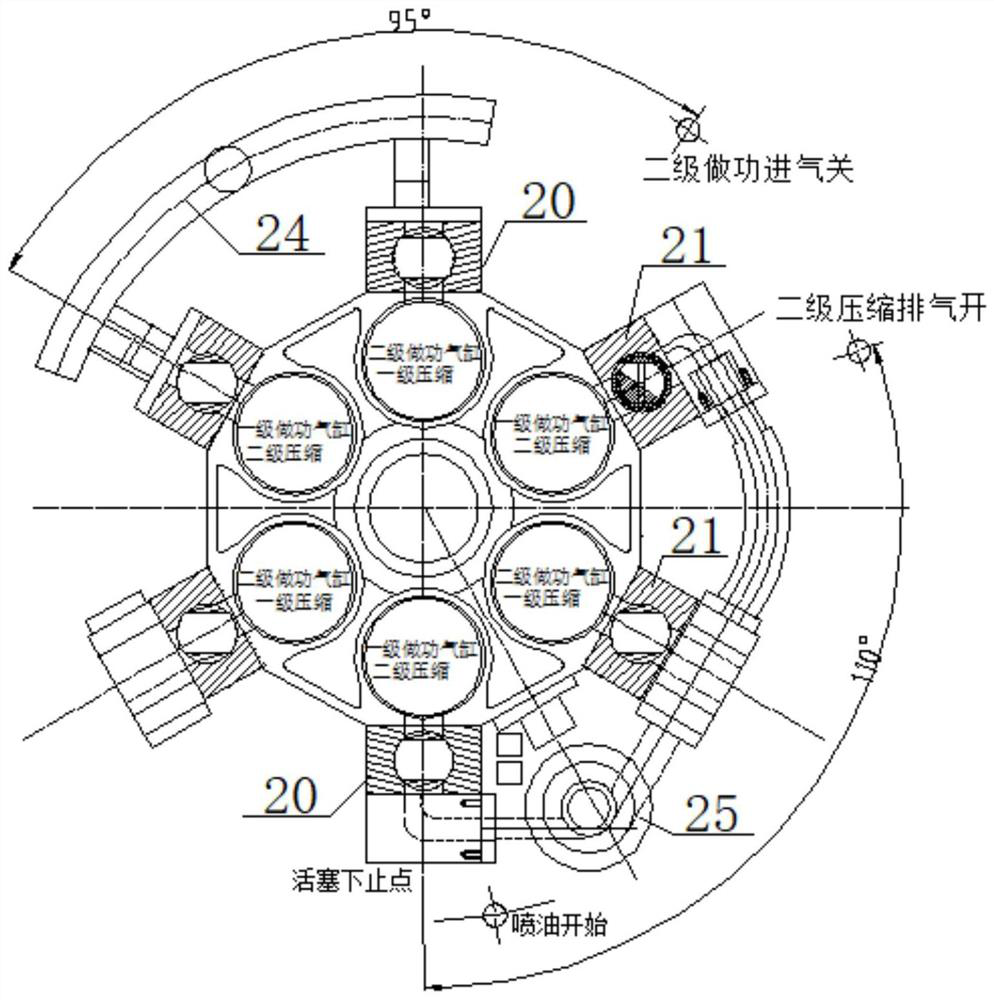

[0074] see Figure 1 to Figure 4 , a swash plate type opposed piston two-stroke external combustion engine, comprising a cylinder block 1, a main shaft hole is opened in the middle of the cylinder block 1, a main shaft 2 is arranged in the main shaft hole, and inclined shafts are arranged at both ends of the cylinder block 1 Disk box 3, the swash plate box 3 is provided with a swash plate 4, and the swash plate 4 is set on the main shaft 2, and the outer periphery of the main shaft hole is evenly arranged with six axially penetrating cylinders 5, and the cylinders 5 Two front and rear pistons 6 are oppositely arranged, and the piston rods 7 of the pistons 6 are all connected with the slider bracket 8 in the swash plate box 3, and the slider bracket 8 is slidably connected with the guide rail on the swash plate box 3, The ball socket 9 of the slider support 8 is slidingly connected with the spherical surface of the hemispherical slider 10 in the swash plate box 3, the plane of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com