Internal rotational flow dual fuel nozzle for chemical regenerative cycle

A chemical regenerative cycle and internal swirl technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of small size of swirl blades, inconvenient processing, long flame length, etc., and achieve the effect of shortening the flame length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

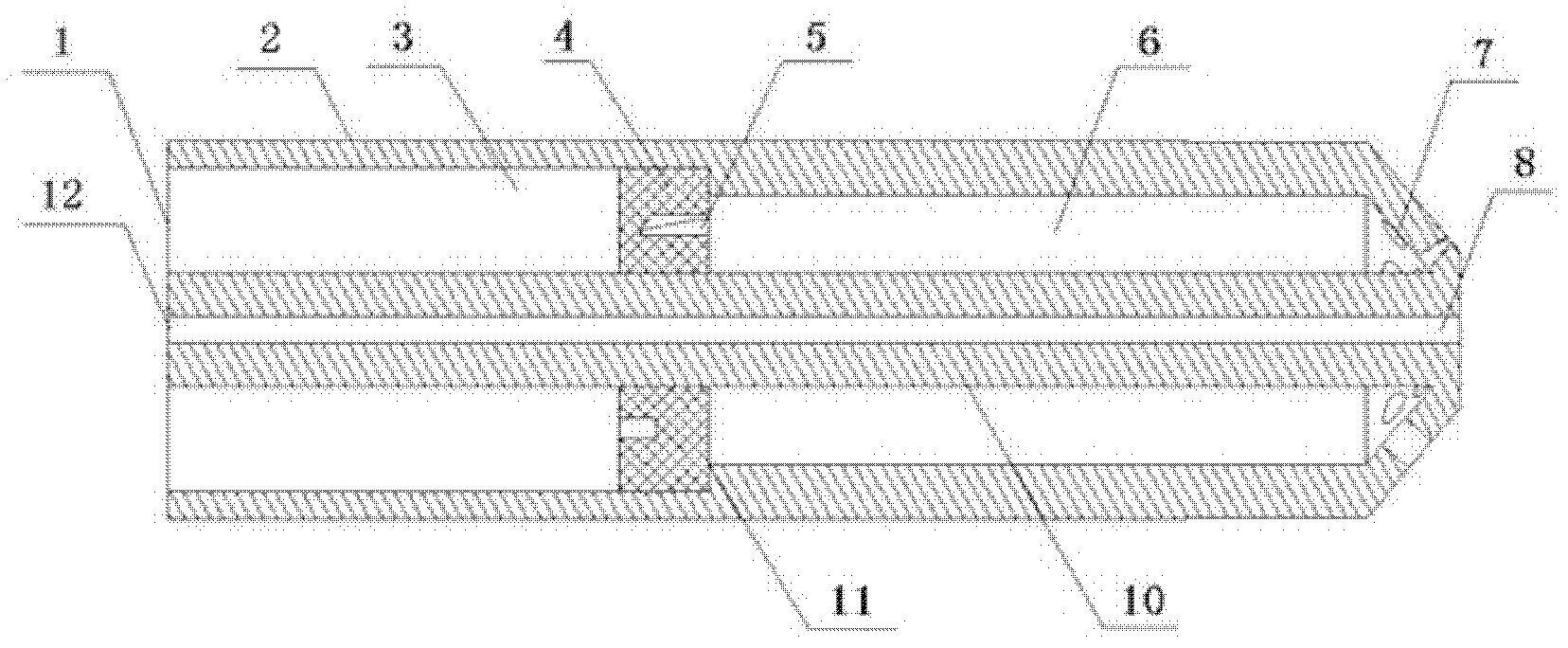

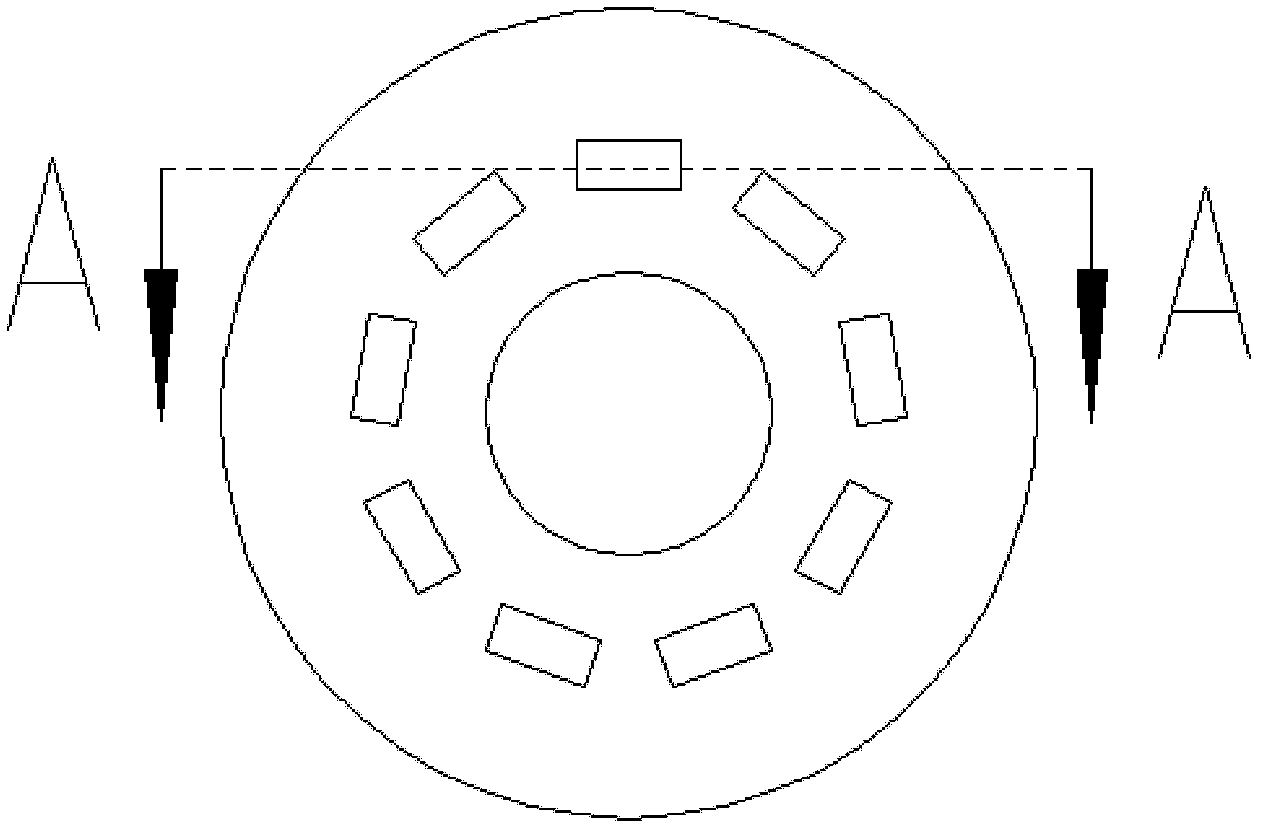

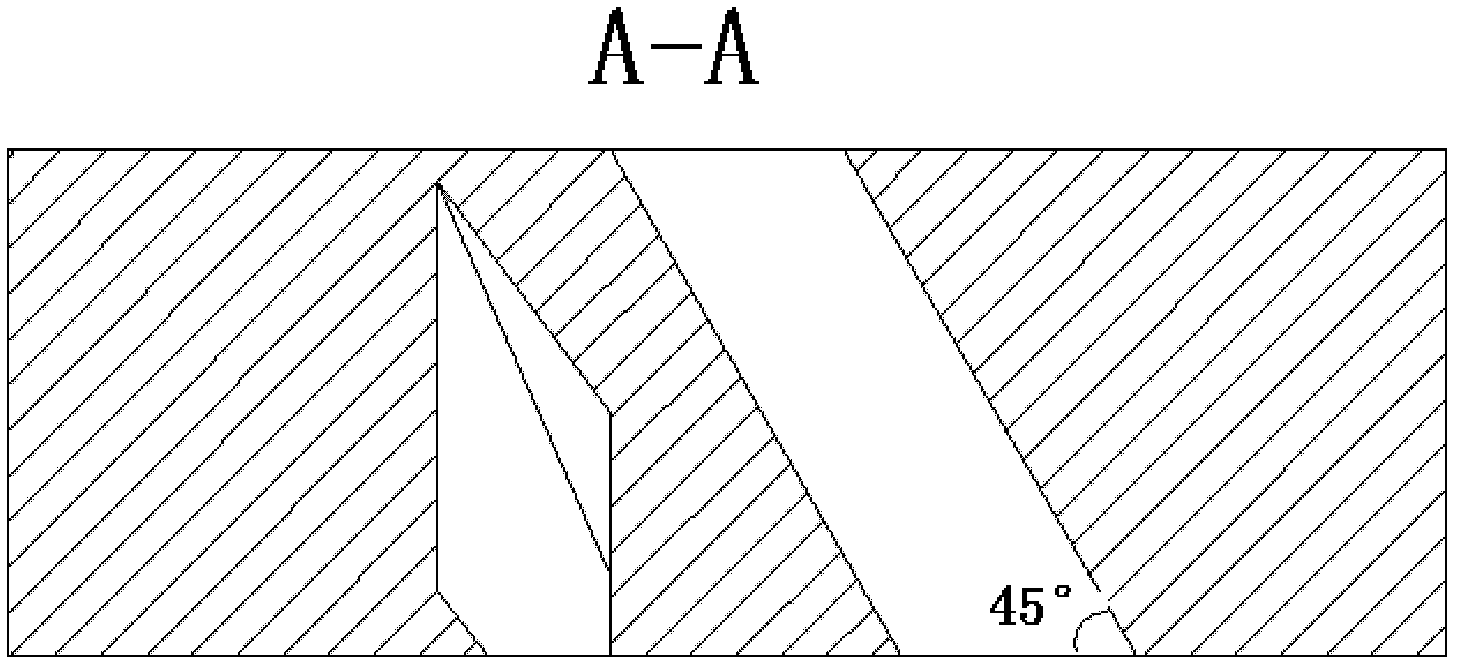

[0017] combine Figure 1~4 , the high-temperature zone of the combustion chamber using cracking cyclone flow blades is relatively front, indicating that the gas fuel and air are mixed ideally; the structure with pores on the head has a certain guiding effect on the outflow of cracking gas, and the high-temperature zone is relatively long and narrow. This is not easy to ablate the wall of the flame tube. The present invention combines the advantages and disadvantages of the above two structures, optimizes and integrates the two structures, and obtains an ideal internal swirling dual-fuel nozzle structure.

[0018] (1) A groove slightly larger than the diameter of the hollow cylindrical pipe of the gas path is processed in the gas path of the dual-fuel nozzle, and a swirl disk with a suitable thickness matching the groove diameter is made, and on the swirl disk Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com