Intelligent, quick and accurate electric control system for turbo-charging adjustment

A turbocharging and electronic control system technology, applied in engine control, machine/engine, internal combustion piston engine, etc., can solve problems such as long response time, rough control state, etc., to achieve increased power, fast computing speed, and rapid boost The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

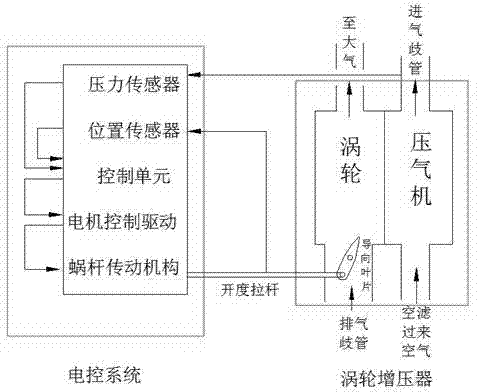

[0014] The pressure sensor is installed at the outlet of the compressor to directly sense the pressure in the intake manifold after the action of the compressor turbine; as an electronically controlled actuator for control execution, the position sensor, control unit, motor control drive control unit, and worm drive mechanism are integrated Together, packaged in a protective shell, which can effectively shield external electromagnetic interference, form a reliable protection and prevent foreign objects from colliding and dust pollution;

[0015] The position sensor adopts the Hall principle, works in a non-contact manner, and has a long working life. After assembly, it is compensated and calibrated by online programming, which can avoid deviations caused by assembly. Precise detection of position;

[0016] Work process of the present invention is:

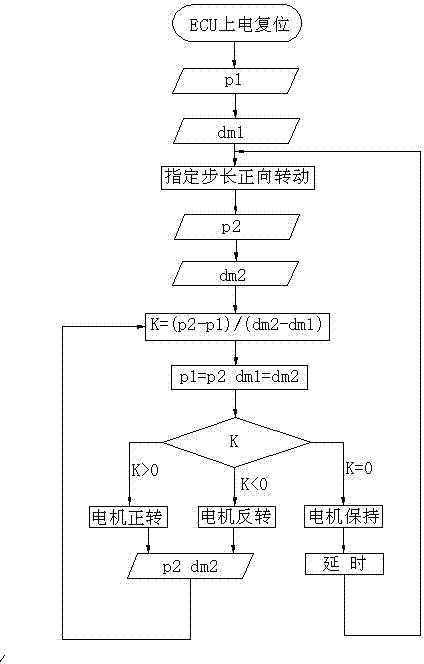

[0017] After the car is ignited and started, the ECU in this control system is powered on and reset. After the ECU is reset, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com