Microemulsion fuel prepared from quantization carbon material, and preparation and apparatus thereof

A quantized, carbon material technology, applied in the field of emulsified water-mixed fuel fuel and preparation, which can solve problems such as calorific reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

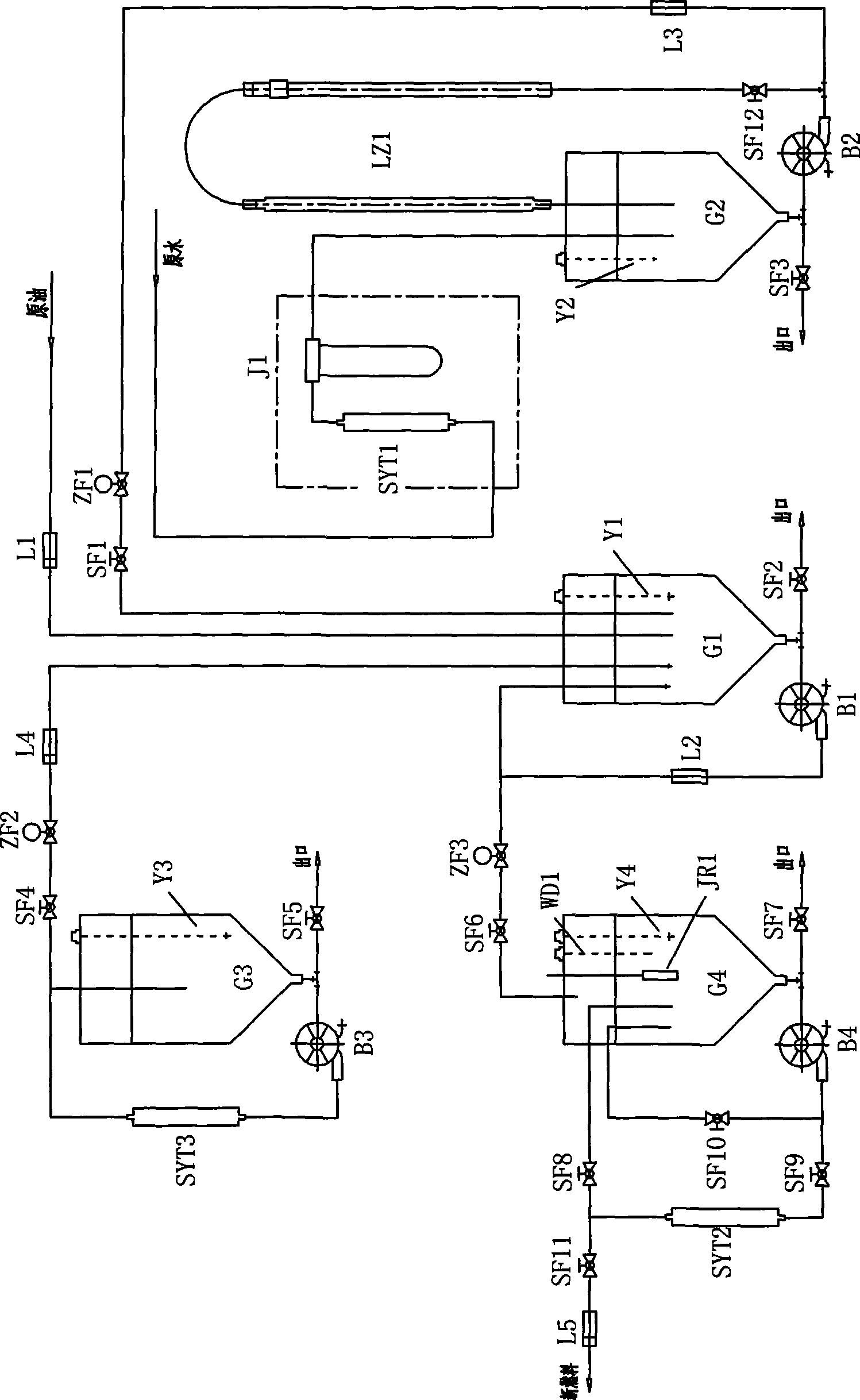

[0063] Such as figure 1 As shown, a preparation equipment for microemulsion fuel oil, including a water quantization system, a quantization carbon material processing system, a mixing system, and a mixing quantization system:

[0064] Wherein the water quantization system includes the first quantization microemulsion machine SYT1, the purifier J1, and the second treatment tank G2 connected in sequence through pipelines, and the outlet of the second treatment tank G2 is divided into two branches, and the second treatment tank G2 is divided into two branches. One branch is connected to a detection outlet through the manual valve three SF3, the second branch is connected to the second water pump B2, and the outlet of the second water pump B2 is divided into two branches, the first branch is connected to the manual valve twelve SF12 And the ionization processor LZ1 and back to the second treatment tank G2, the second branch is connected to the flow meter three L3, the automatic co...

Embodiment 2

[0094] The ratio of the raw material parts by weight of the quantized microemulsion fuel oil of the present invention (English abbreviation NANO-OIL) is as follows:

[0095] Light oil: 85

[0096] Ionic activated water: 15

[0097] Quantized carbon material material liquid: 0.1

[0098] Catalytic metal salts: trace amounts

[0099] Adjust the pH value to 5-7.

[0100] The electron micrograph of the microemulsion fuel oil prepared according to this embodiment is shown in Figure 5 .

[0101] All the other are the same as embodiment one.

Embodiment 3

[0103] The ratio of the raw material parts by weight of the quantized microemulsion fuel oil of the present invention (English abbreviation NANO-OIL) is as follows:

[0104] Heavy oil: 85

[0105] Ion activated water: 15

[0106] Quantized carbon material material liquid: 0.1

[0107] Catalytic metal salts: trace amounts

[0108] Adjust the pH value to 5-7.

[0109] The electron micrograph of the microemulsion fuel oil prepared according to this embodiment is shown in Figure 6 .

[0110] All the other are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com