Gas turbine and its combustion chamber.

A combustor and turbine technology, applied in the field of combustors, can solve problems such as difficult access to combustors, insufficient air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0039] first embodiment

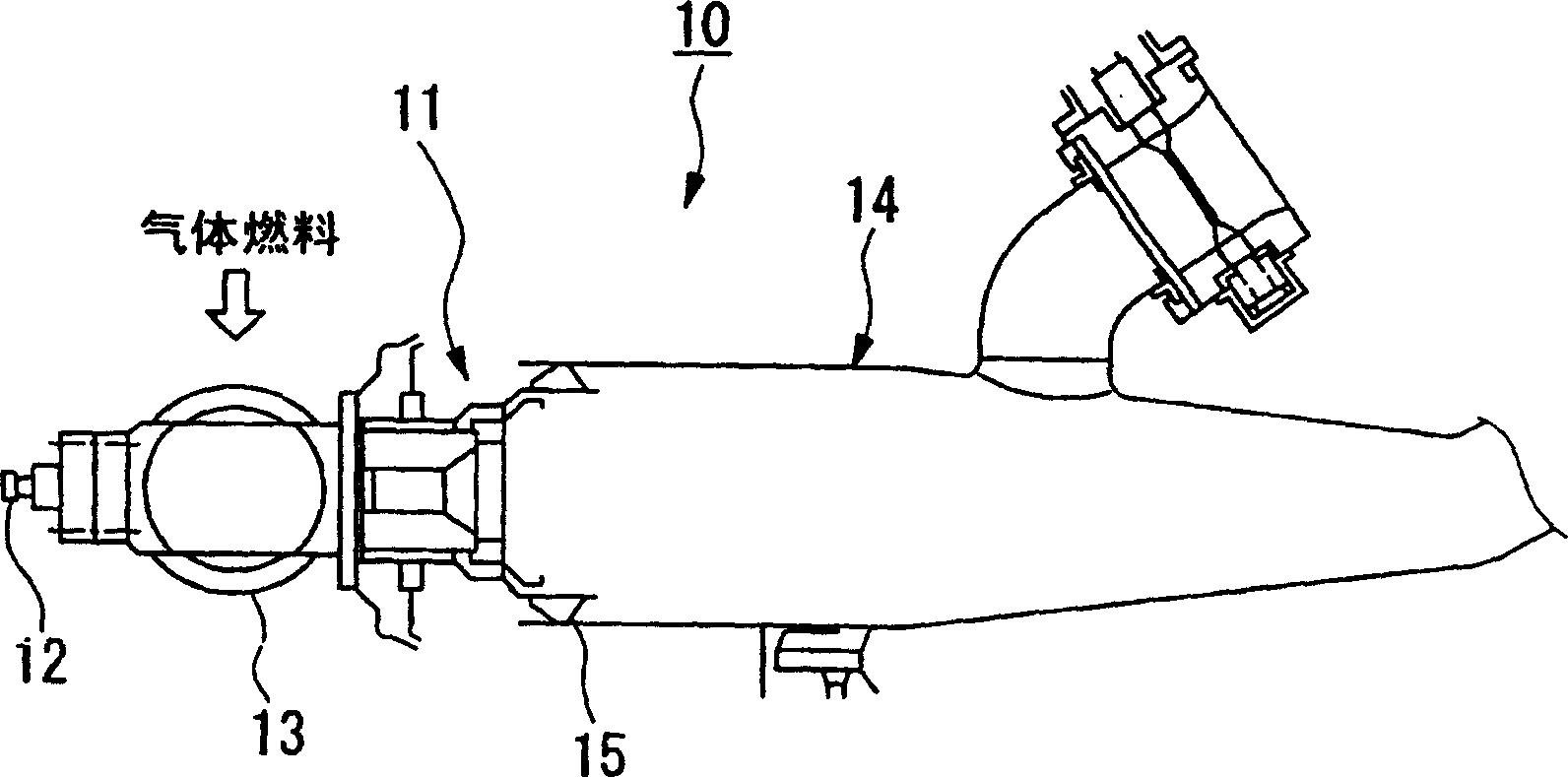

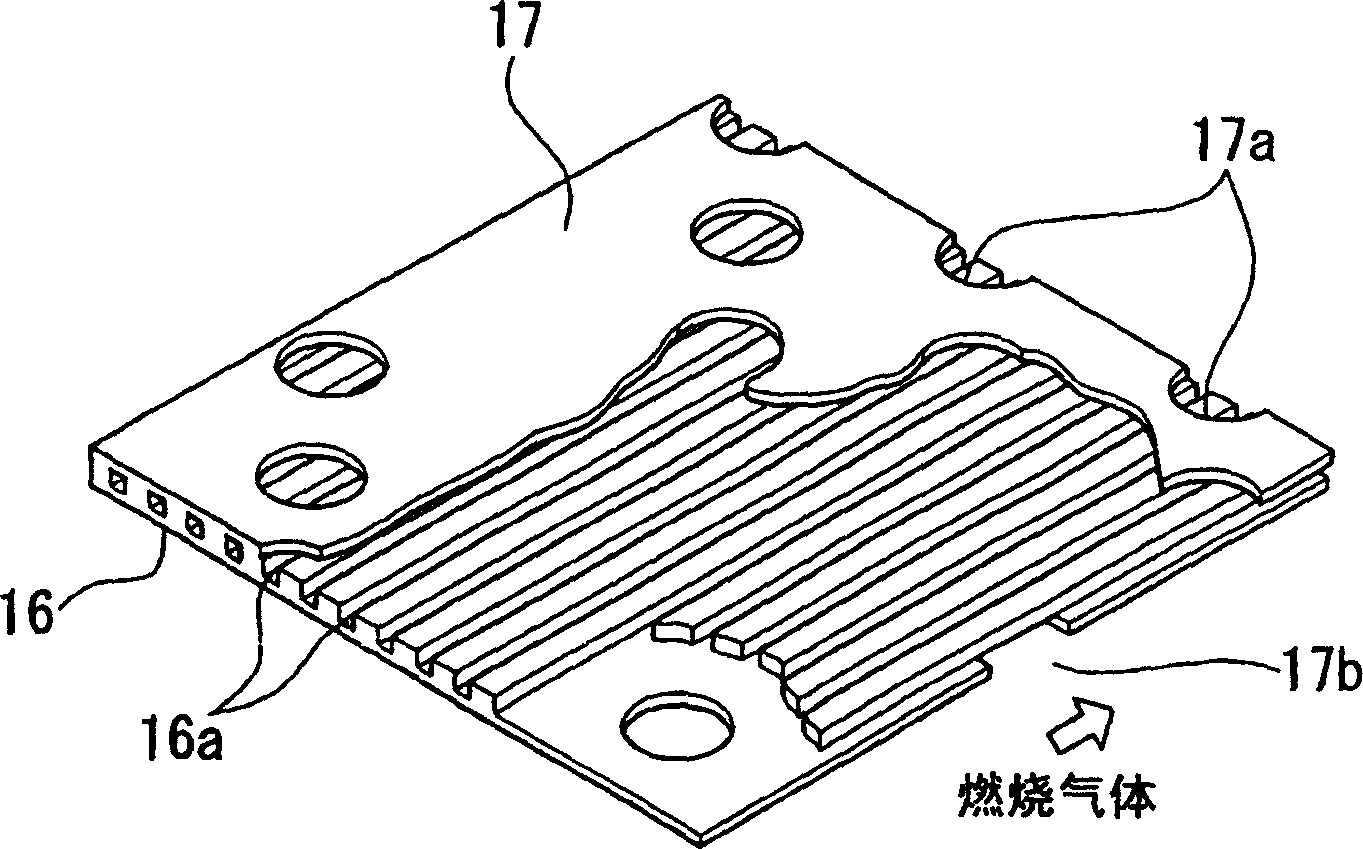

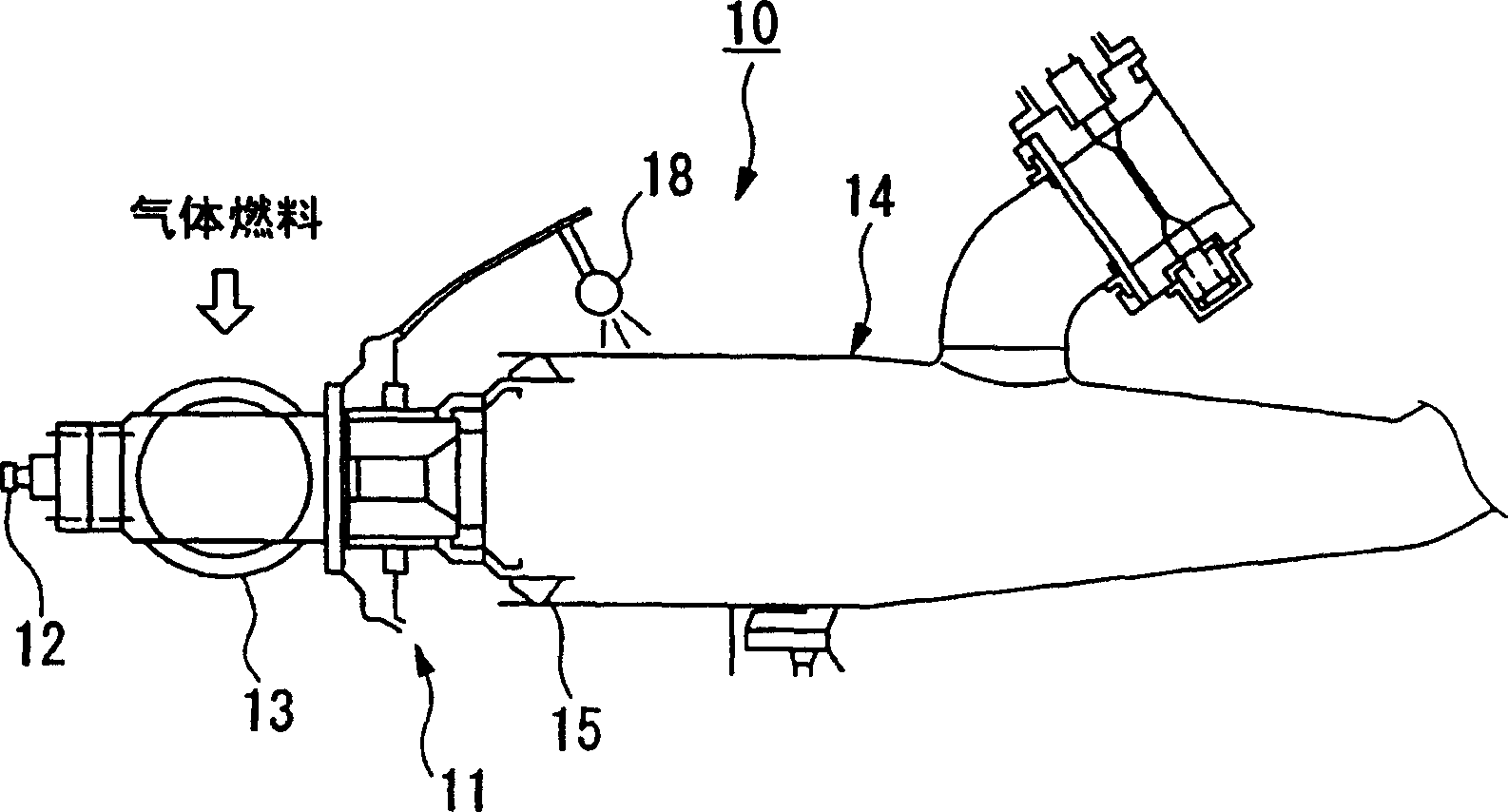

[0040] figure 1 and figure 2 It is the first aspect of the combustion chamber of the present invention. More precisely, figure 1 is a cross-sectional view of the combustion chamber. figure 2 An important part of the combustion chamber for cooling operation. figure 1 The illustrated combustor combusts fuel to produce combustion gases that drive a turbine (not shown). The combustion chamber 10 has a nozzle portion 11 .

[0041] A pilot nozzle 12 and a main nozzle 13 are contained in the nozzle section 11 . Air compressed by an air compressor (not shown in the figure) is supplied to the nozzle portion 11 to be mixed with fuel supplied from the pilot nozzle 12 . Here the mixture of air and fuel is ignited; thereby forming a pilot flame there.

[0042]The main nozzle 13 injects fuel. Guide the flame to ignite the fuel. The igni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com