Diesel engine with wire protection cover for engineering machinery

A technology for construction machinery and diesel engines, which is applied in the direction of mechanical equipment, machines/engines, electrical components, etc. It can solve problems such as wire damage, failure to protect wires, and affect the normal operation of diesel engines, so as to ensure safety, good protection, and normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

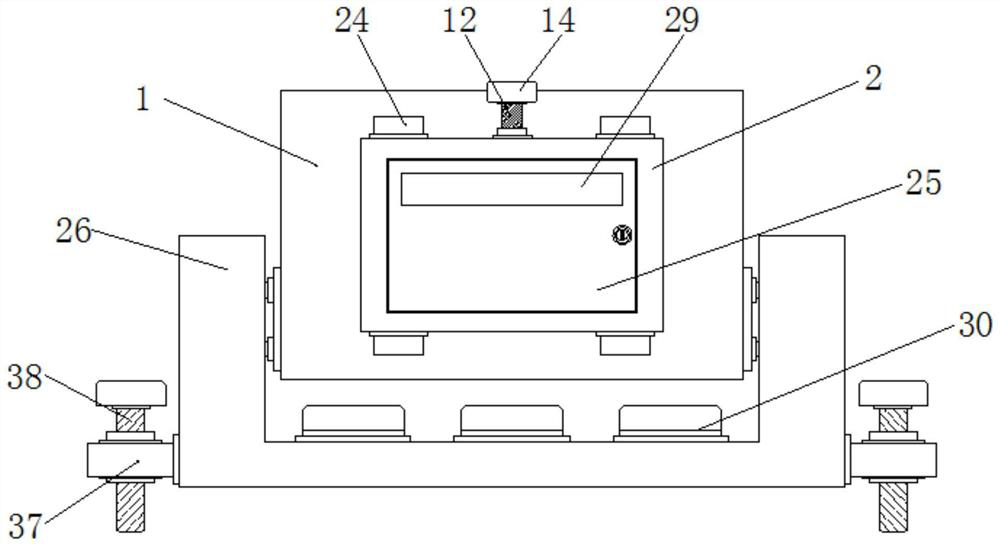

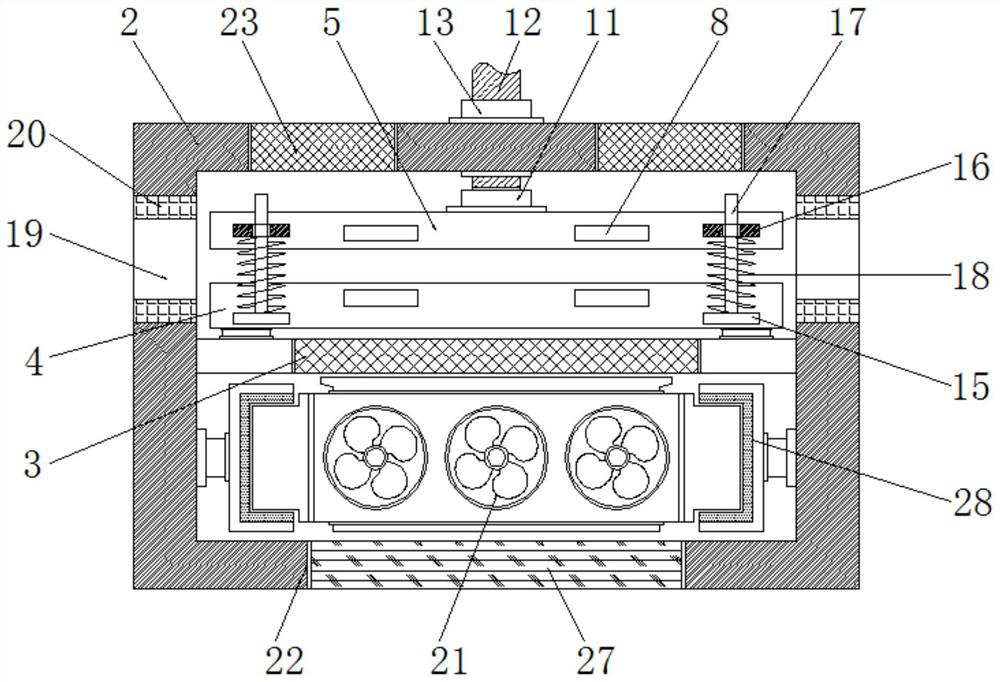

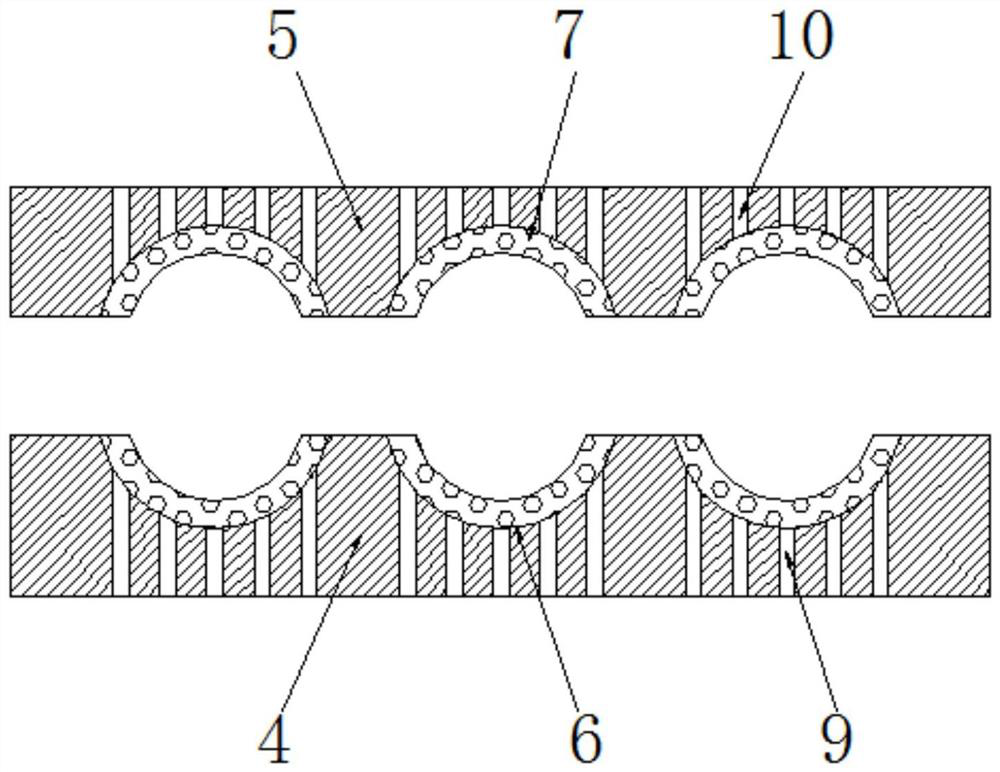

[0030] Embodiment one, such as Figure 1-5 As shown, a diesel engine with a wire protection cover for engineering machinery according to an embodiment of the present invention includes a diesel engine body 1, a cover body 2 is installed on the outer side of the diesel engine body 1, and the inner middle part of the cover body 2 is installed There is a grid plate 3, a support plate 4 is installed on the top of the grid plate 3, a movable plate 5 is installed directly above the support plate 4, and the side of the movable plate 5 and the support plate 4 is close to each other There are several wire grooves 6 on the sides, and arc-shaped perforated rubber plates 7 are installed inside the wire grooves 6, and temperature sensors 8 are installed on the outer sides of the support plate 4 and the movable plate 5, On the support plate 4 and the movable plate 5 corresponding to the wire groove 6, a plurality of cooling holes 9 and 2 10 are respectively opened, and a movable shaft 11 is...

Embodiment 2

[0031] Embodiment two, such as figure 2 As shown, the inside of the air inlet 22 is equipped with a dust-proof screen 27; the dust-proof screen 27 can ensure that the air intake of the fan 21 will not be mixed with dust, so as to achieve better heat dissipation. effect, which in turn facilitates the ability to better meet people's needs.

Embodiment 3

[0032] Embodiment three, such as figure 2 As shown, a fixed frame 28 is installed on both sides of the inside of the cover 2 corresponding to the fan 21, and the side of the fixed frame 28 away from the fan 21 is connected to the cover 2. The inner side of the fan 21 is fixedly connected; through the fixed frame 28, the fan 21 can achieve better stability, so as to facilitate better heat dissipation operation, and further facilitate to better meet people's use needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com