A physical air-cooling heat dissipation device based on laser cutting equipment head

A laser cutting and heat dissipation device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to use the high temperature of the cutting head, waste of resources, and high cost of air compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

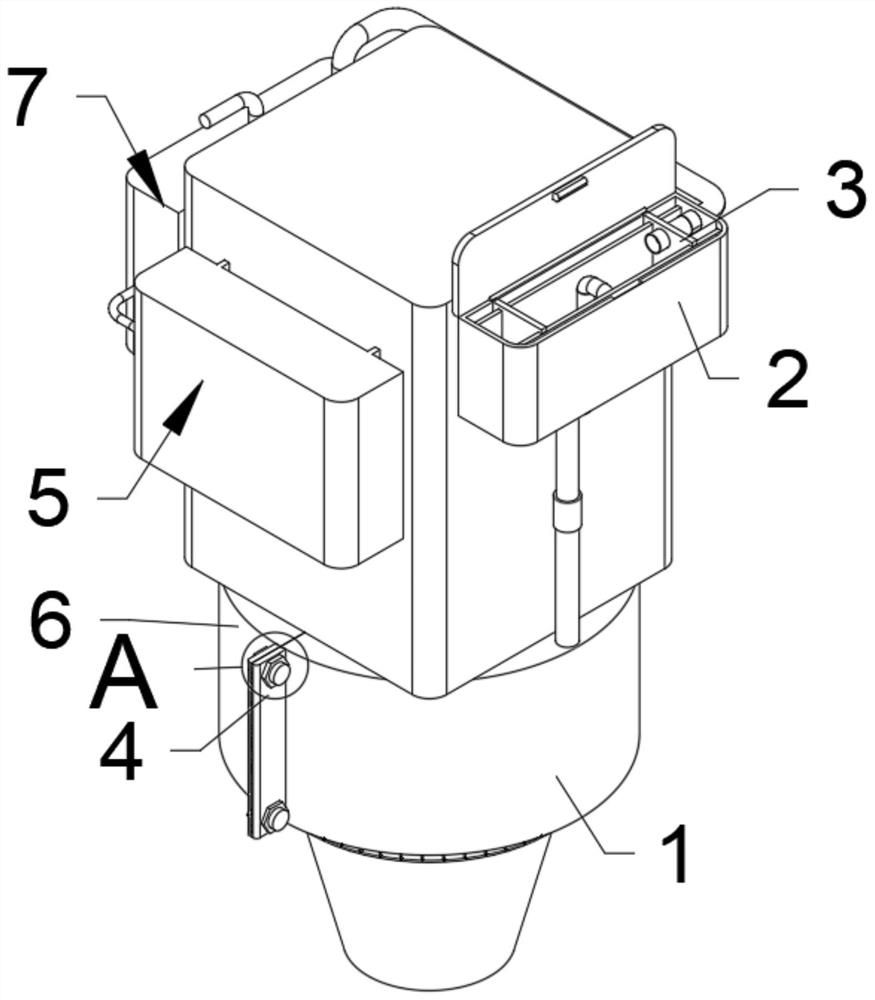

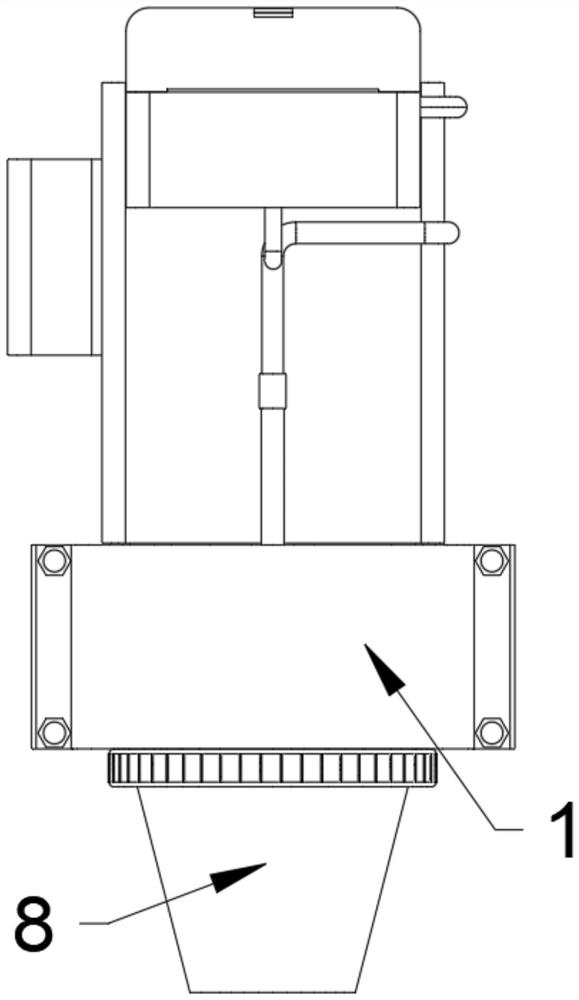

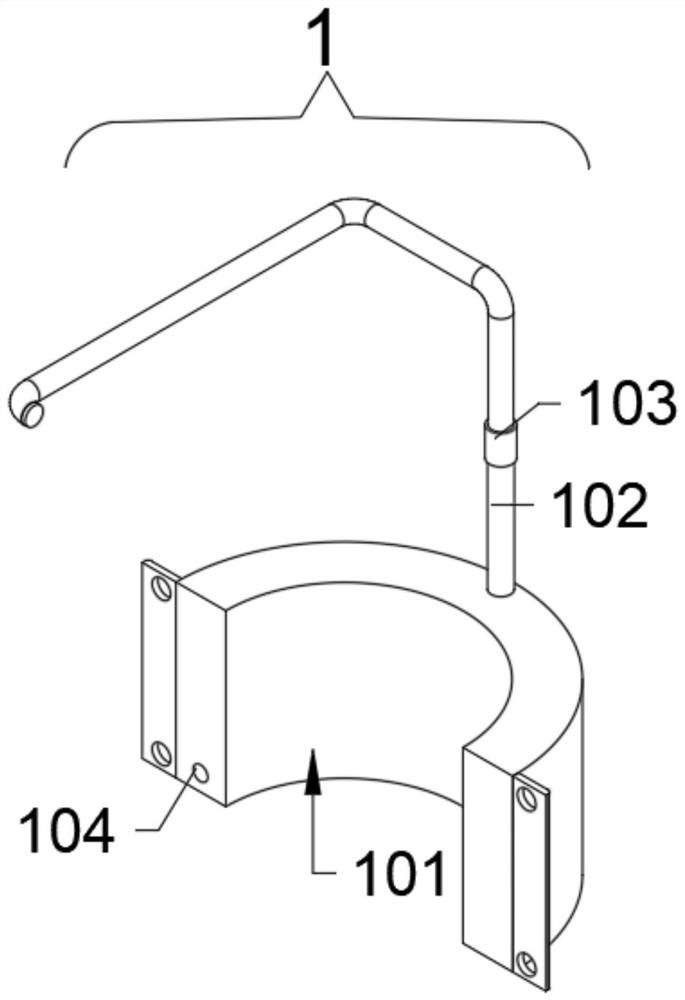

[0033] as attached figure 1 to attach Figure 10 Shown:

[0034]The present invention provides a physical air-cooling heat dissipation device based on the laser cutting equipment head, including: a return cooling cover 1, a pneumatic mechanism 2, and a condensation mechanism 7, and the return cooling cover 1 and the supply flow cooling cover 6 are fixedly connected by a fixing mechanism 4 On the position of the outer peripheral surface of the laser equipment head 8; the condensing mechanism 7 is fixedly connected to the left end surface of the laser equipment head 8, and is connected with the air cooling mechanism 5; the air cooling mechanism 5 includes a bellows 501 and an air cooling support plate 502 , a filter screen 503 and a pneumatic fan 504, the bellows 501 is hollow inside and designed with a front opening, the filter screen 503 is fixedly connected to the front opening of the bellows 501, the pneumatic fan 504 is axially connected to the inner position of the bellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com