Self-circulation type efficient physical circulation cooling laser cutting head

A laser cutting head and circulating cooling technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of sheet cutting failure, cannot be processed, cannot be recycled, etc., and achieve the effect of preventing cutting failure and efficient cooling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

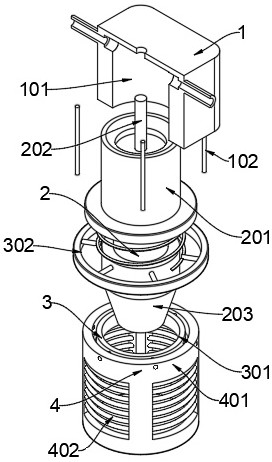

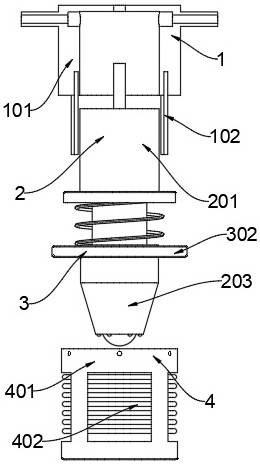

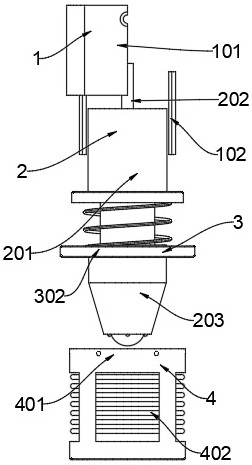

[0049] as attached figure 1 to attach Figure 8 Shown:

[0050] The present invention provides a self-circulating efficient physical circulation cooling laser cutting head, including: a maintenance mechanism 1,

[0051] The main body of the maintenance mechanism 1 is designed as a cuboid structure, and the bottom center and the top center of the main body of the maintenance mechanism 1 are provided with circular holes, and the diameter of the circular hole on the upper side is smaller than the diameter of the circular hole on the lower side. The inner bottom of the maintenance mechanism 1 is also plugged with a laser mechanism 2 .

[0052] Among them, recycling organization 3 also includes:

[0053] The collection assembly 302, the main body of the collection assembly 302 is designed in a circular structure, and the diameter of the collection assembly 302 is larger than the diameter of the recovery assembly 301, and the inner side of the collection assembly 302 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com