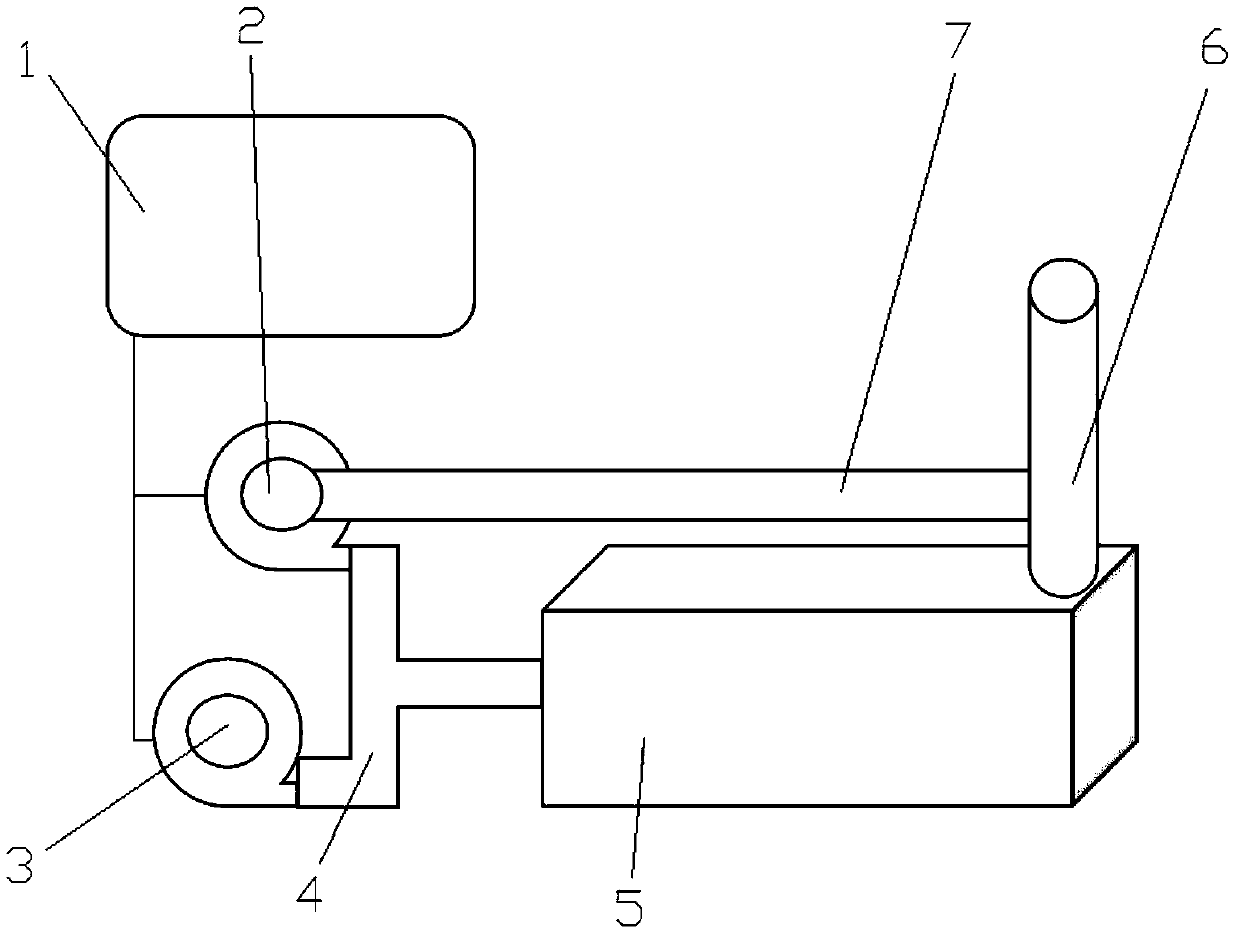

Low-nitrogen combustion fresh air and flue gas proportion regulation equipment

A proportional adjustment and low-nitrogen combustion technology, which is applied in the direction of combustion method, combustion type, and controlled combustion, can solve the problems of low-efficiency low-nitrogen combustion, achieve the effects of improving low-nitrogen combustion efficiency, intuitive comparison results, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

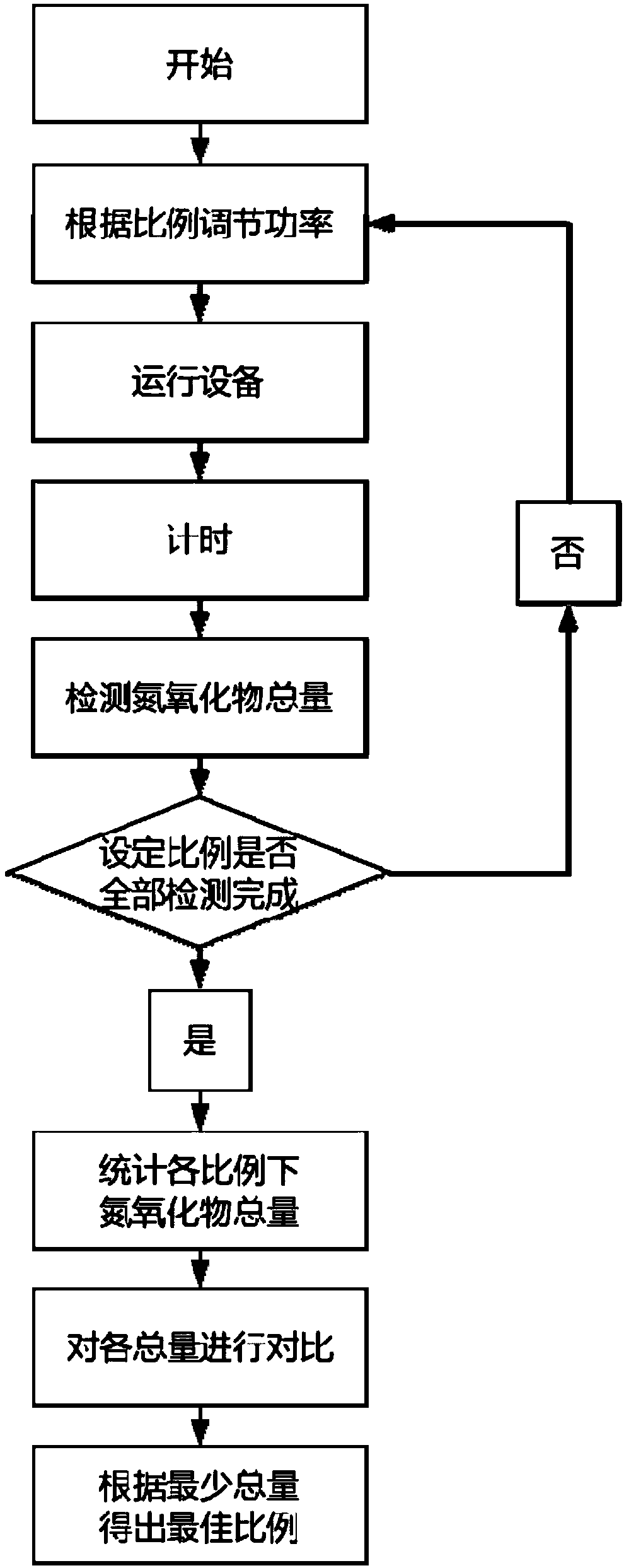

Method used

Image

Examples

Embodiment 1

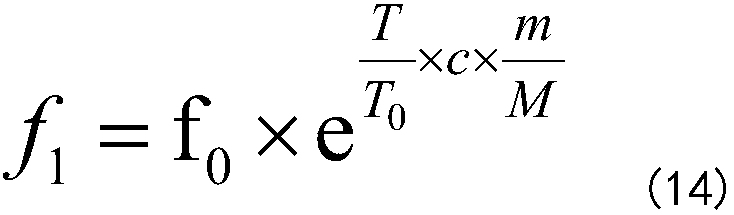

[0079] In this embodiment, the equipment is selected to measure the output of nitrogen oxides in the flue gas. The boiler capacity is 20T, the boiler power is 14MW, and the ratio of flue gas to air is from 80:20 to 10:90, and every 5% is a gear. Use the side described in the present invention to measure it, and measurement result is as shown in table 1

[0080] Table 1

[0081]

[0082] After operation, it can be obtained: the amount of nitrogen oxides is reduced by 100-150mg / m3, the calculated dosage of denitrification is 42.86%, and the operating cost of dosing is reduced: 68% / 42.86% = 1.59-1 = 59%; the proportion of fresh air is reduced by 30%, Reduce the heat taken away by smoke exhaust, and the energy saving can reach about 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com