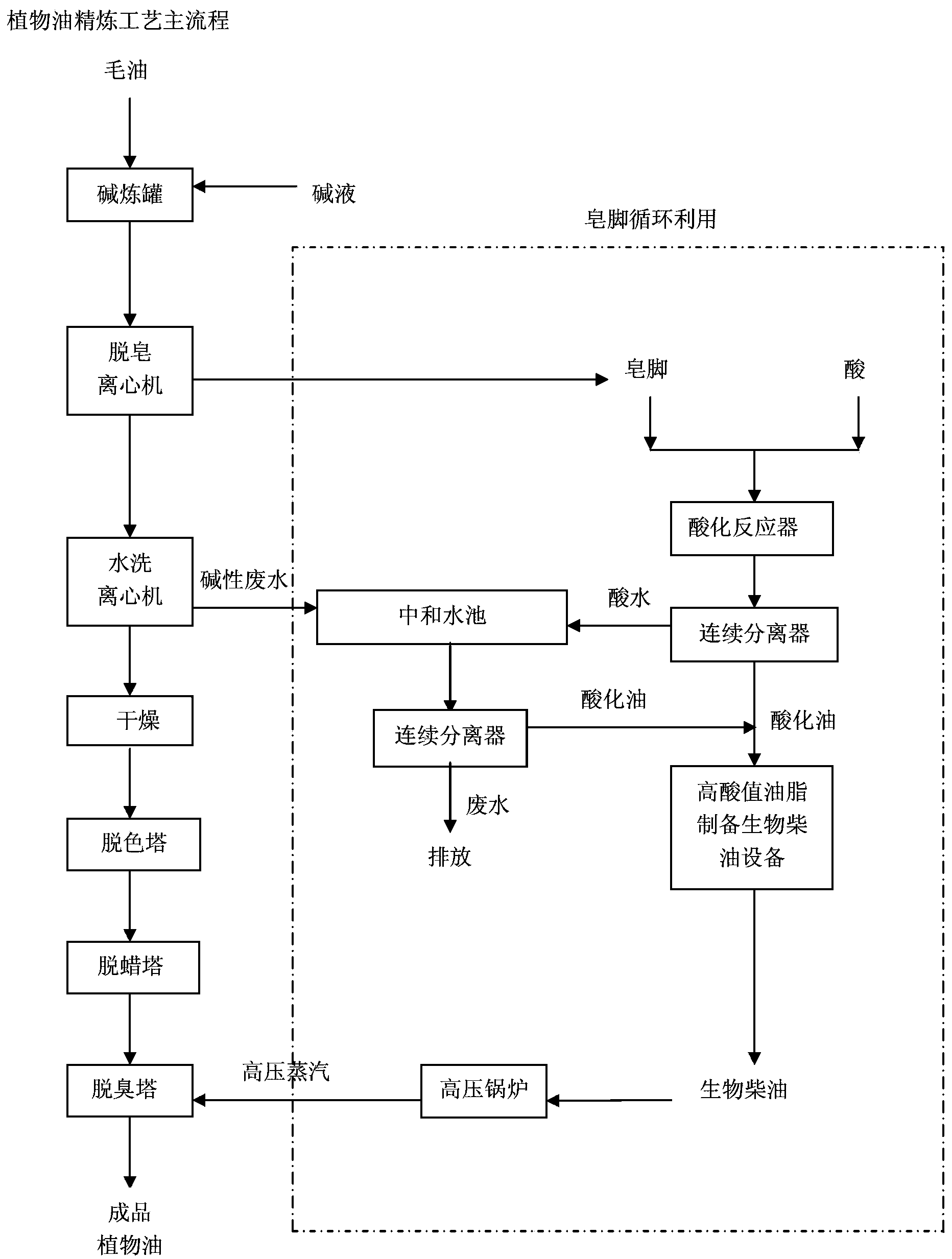

Recycling process for alkali refining by-product, namely soapstock in refining vegetable oil and reactor

A vegetable oil and by-product technology, applied in the petroleum industry, recycling technology, biofuels, etc., can solve the problems of secondary pollution, the unwillingness of large oil processing plants to process soapstock, and the inability of acidified oil to be used efficiently, so as to prevent secondary pollution. The effect of pollution, reducing alkaline wastewater discharge and improving raw material utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

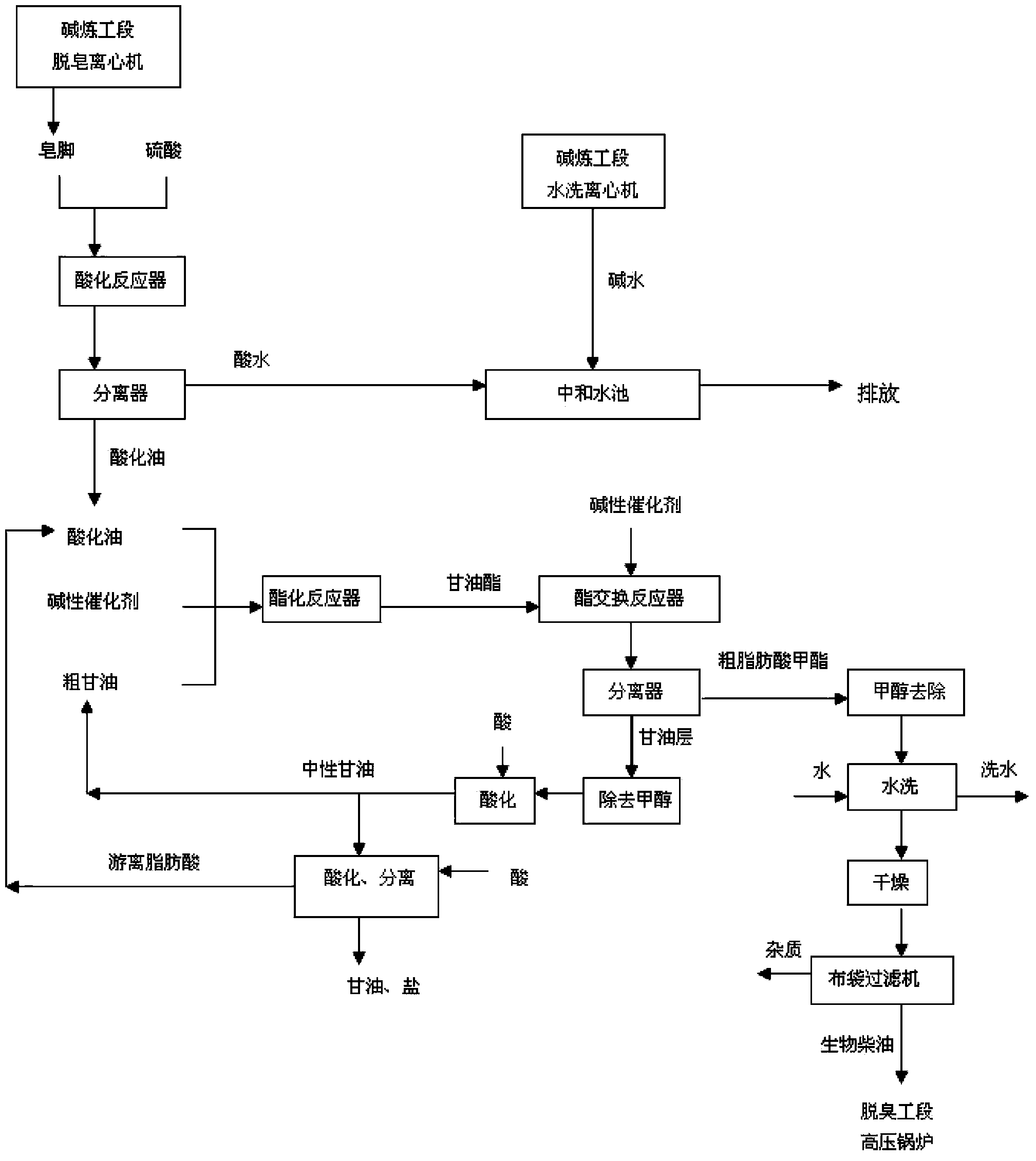

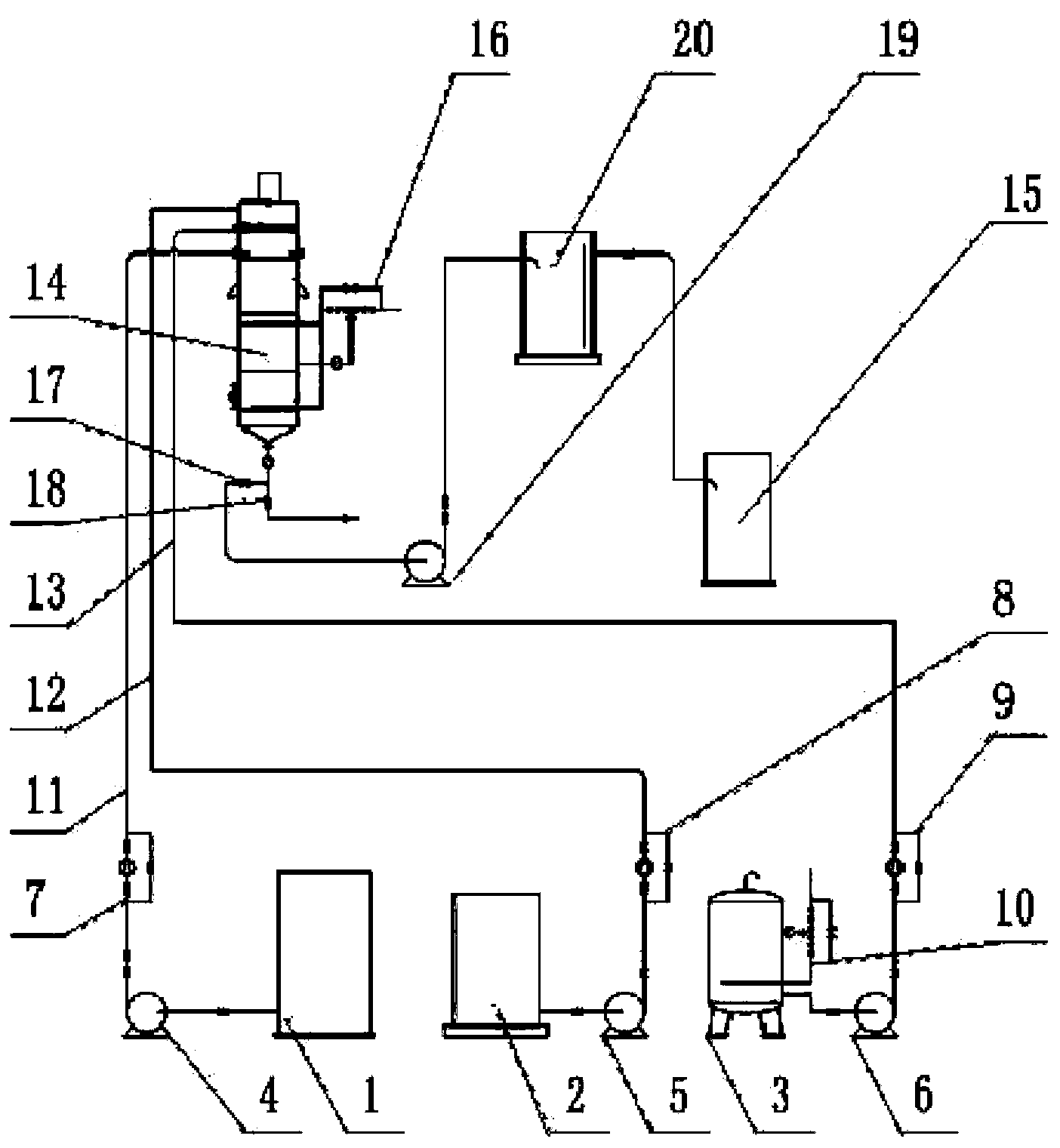

Method used

Image

Examples

Embodiment 1

[0072] (1) Preparation of biodiesel from soybean oil soapstock:

[0073] ①Acidification of soybean oil soapstock: Take 200g of soap obtained from the centrifuge in the refining workshop and add it to the reaction kettle, add 30g of 98% sulfuric acid, add 30g of hot water, wait until the temperature rises to 60°C, and react for 3 hours to obtain 83g of acidified oil in the upper layer. Lower layer acid water 172g;

[0074] 2. Esterification of acidified oil: get step ① acidified oil 80g (acid value 151.35mgKOH / g) and add in the reactor, add granular sodium hydroxide catalyst 0.16g, add 24g crude glycerin (glycerol mass content is 50%), react The kettle was evacuated to a pressure of 9000 Pa, while stirring continuously, and the timing was started when the temperature reached 200°C. After 2 hours of esterification reaction, the esterified oleic acid value was measured to be 0.48 mgKOH / g;

[0075] ③Alcoholysis of esterified oil: Add methanol solution (containing 0.2g KOH and 16g...

Embodiment 2

[0082] (1) Preparation of biodiesel from soybean oil soapstock:

[0083] ①Acidification of soybean oil soapstock: Take 200g of the soap obtained from the centrifuge in the refining workshop and add it to the reaction kettle, add 60g of 50% sulfuric acid, wait until the temperature rises to 150°C, and react for 0.5h to obtain 82g of acidified oil in the upper layer and 172g of acidic water in the lower layer ;

[0084] 2. Esterification of acidified oil: get step ① acidified oil 80g (acid value 152.57mgKOH / g) and add in the reactor, add granular potassium hydroxide catalyst 0.64g, add 48g crude glycerin (glycerol mass content is 90%), react The kettle was evacuated to a pressure of 10000Pa while stirring continuously. The temperature of the cooling water in the condenser was 60°C. When the temperature reached 230°C, the timing was started. After 4 hours of esterification reaction, the acid value of the esterified oleic acid was measured to be 1.30 mgKOH / g;

[0085] ③Alcoholys...

Embodiment 3

[0088] (1) Preparation of biodiesel from rapeseed oil soapstock:

[0089] ①Acidification of rapeseed oil soapstock: Take 200g of soap obtained from the centrifuge in the refining workshop and put it into the reaction kettle, add 40g of 85% phosphoric acid, wait until the temperature rises to 90°C, and react for 3 hours to obtain 80g of acidified oil in the upper layer and 178g of acidic water in the lower layer ;

[0090] 2. Esterification of acidified oil: Take step 1. Add 80 g of acidified oil (acid value 168.61 mgKOH / g) into the reactor, add 0.4 g of granular potassium hydroxide catalyst, add 16 g of crude glycerin (glycerol mass content is 70%), and react The kettle was evacuated to a pressure of 2000Pa while stirring continuously. The temperature of the cooling water in the condenser was 30°C. When the temperature reached 170°C, the timer was started. After 2 hours of esterification reaction, the acid value of the esterified oleic acid was measured to be 0.26 mgKOH / g;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com