Asphalt mixture MLC modifier

A technology of asphalt mixture and modifier, which is applied in the field of asphalt modifier, can solve the problems of reducing the road performance of asphalt mixture, high production and construction temperature, and easy cracking of asphalt, so as to improve the water damage resistance and improve the Anti-rutting ability and the effect of prolonging the anti-fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

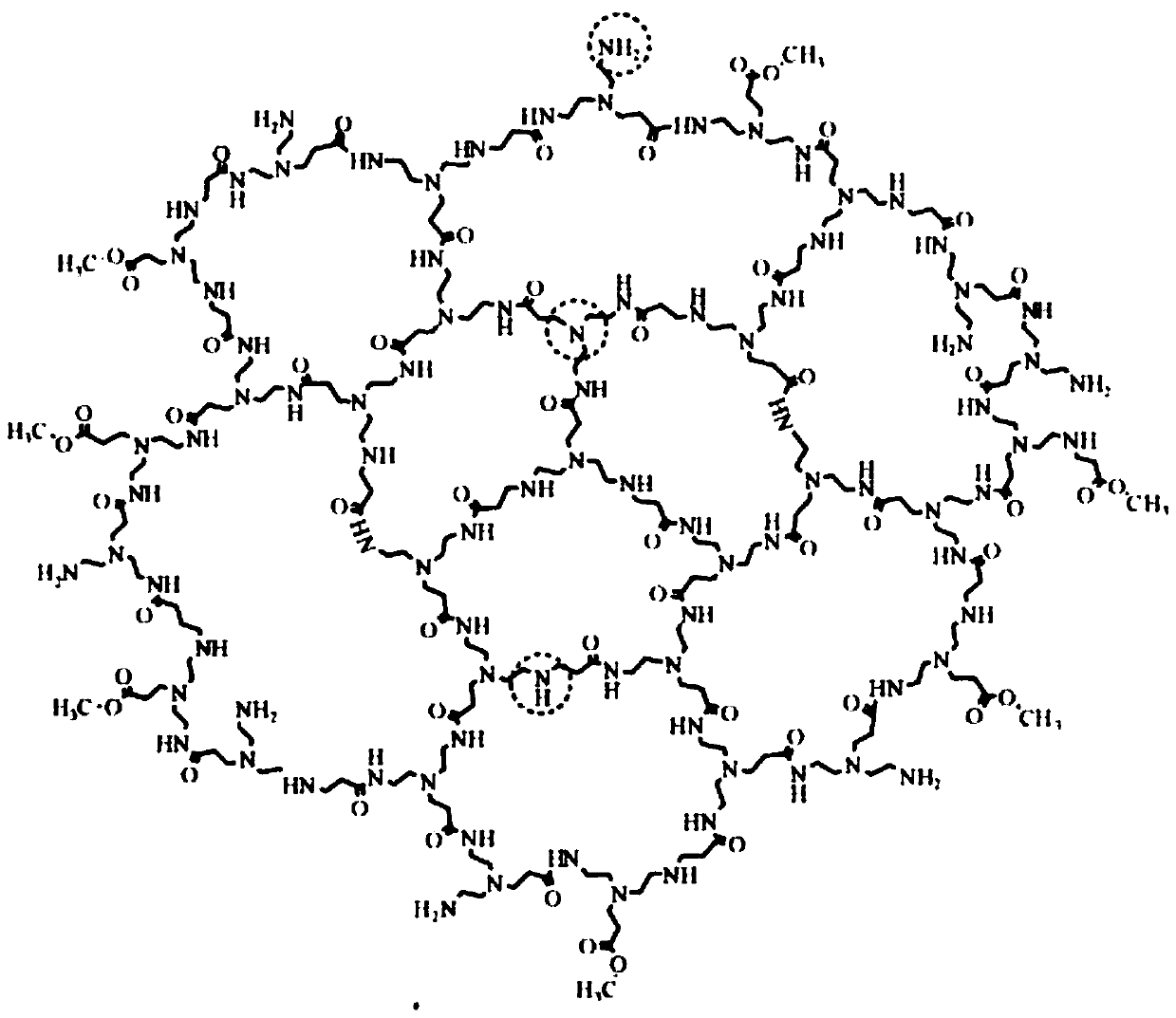

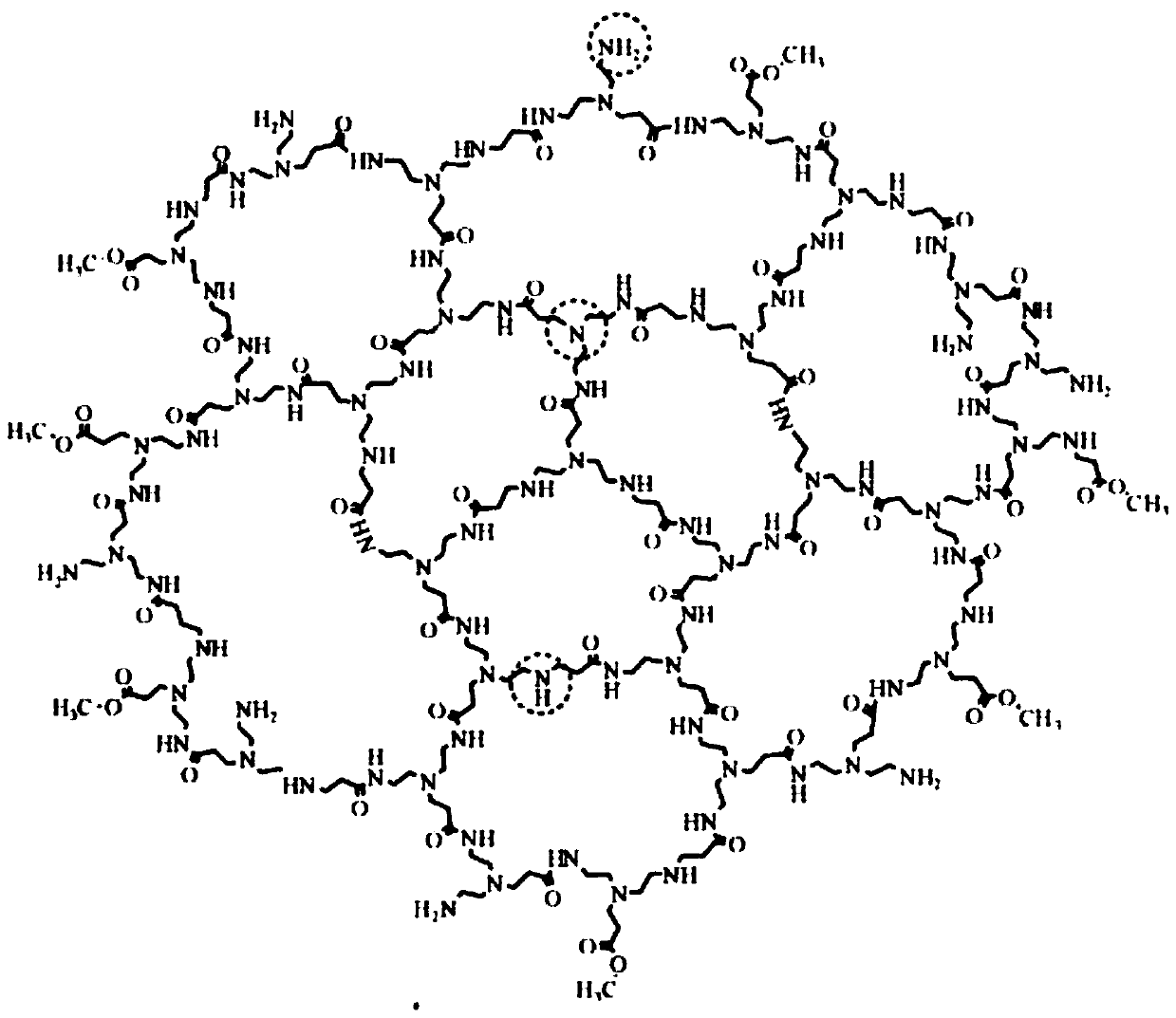

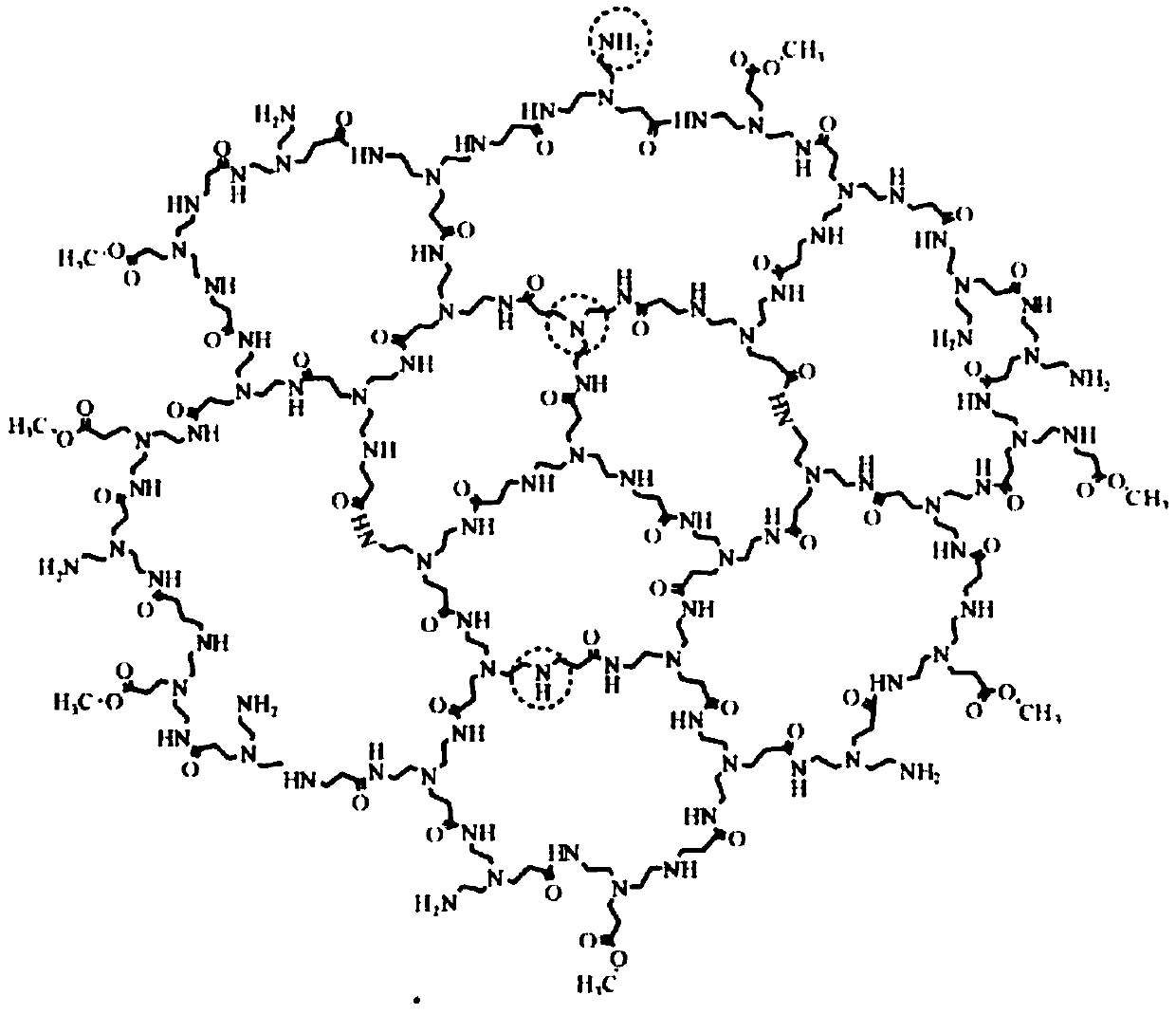

[0026] An asphalt mixture MLC modifier involved in this embodiment includes powdery component A and granular component B. Component A includes 30-50 parts by mass of polyethylene terephthalate, 10-20 parts by mass of polyamide, 10-20 parts by mass of polyolefin, 10-30 parts by mass of aromatic oil, 5-10 parts by mass Acrylamide in parts by mass and hydrazine hydrate in 0.5-1 parts by mass. Component B comprises the hyperbranched polymer of 20-30 mass parts, the rubber of 50-60 mass parts, the natural latex of 40-50 mass parts, the vulcanizing agent of 1-2 mass parts, the surfactant of 0.5-0.8 mass parts agent, 3-5 parts by mass of tackifying resin, 5-7 parts by mass of zinc oxide, and carbon black of 20-30 parts by mass.

[0027] Specifically, the preparation process of component A is as follows:

[0028] Step A1, heating polyethylene terephthalate, polyamide, and polyolefin to make them liquid. The polyolefin is polyethylene or polypropylene, and polyethylene is selected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com