Glass melting furnace and asymmetric characteristic dynamic control method for flue gas pipe network of glass melting furnace

A glass melting furnace, dynamic control technology, applied in the selection of control equipment and instruments, liquid level system of glass melting furnace, control system field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

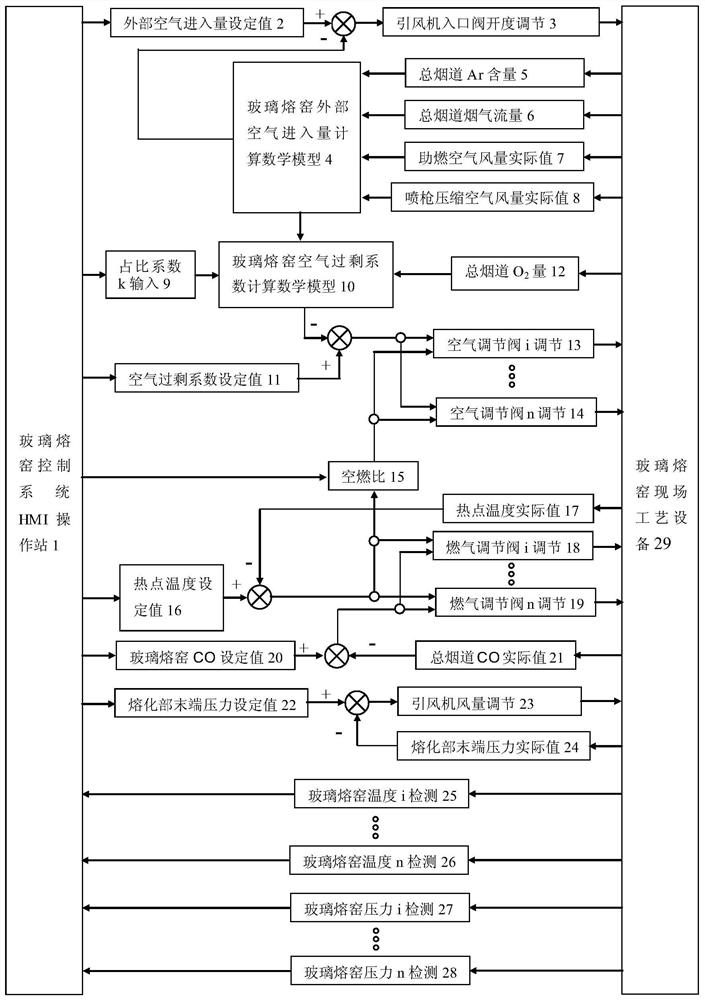

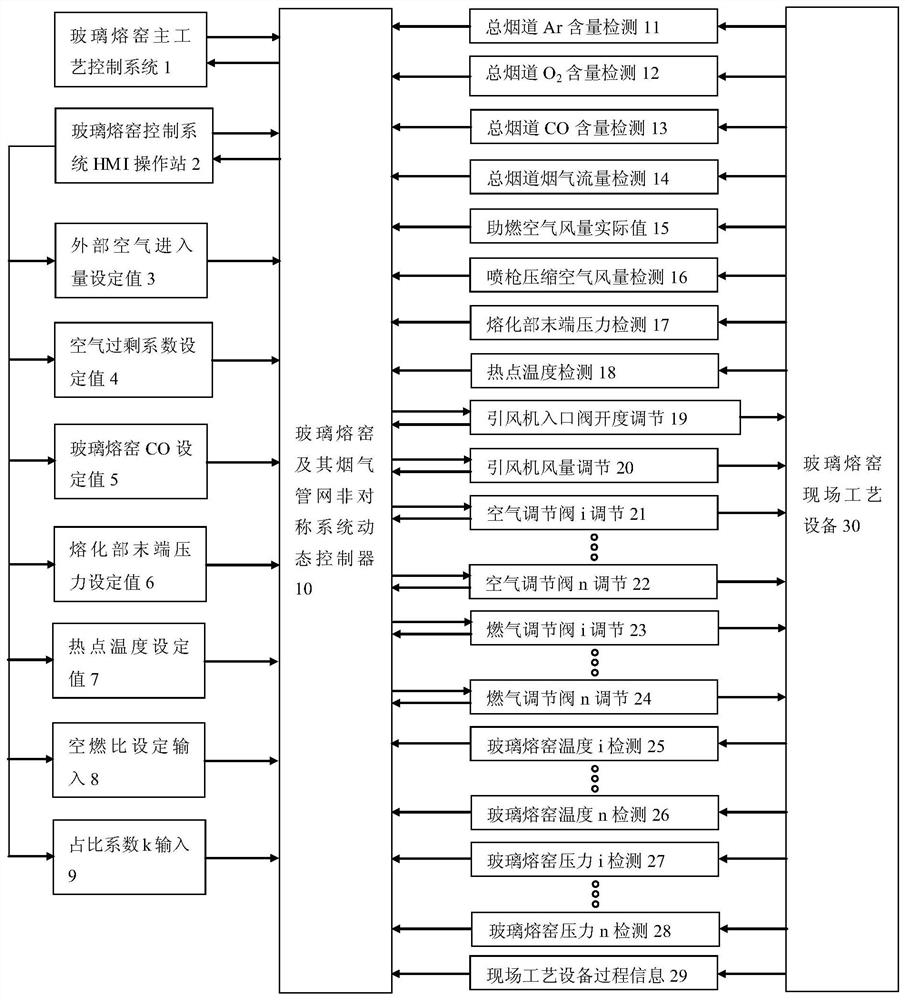

Method used

Image

Examples

Embodiment Construction

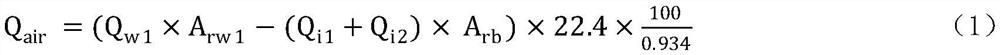

[0013] Basic terms and definitions: The air excess coefficient in the glass melting furnace system is also called excess air coefficient or excess air coefficient, which is defined as "the ratio of the actual air requirement to the theoretical air requirement during fuel combustion", represented by the letter α.

[0014] According to the definition, the air excess coefficient refers to the result obtained by the combustion system of the glass melting furnace at the set air-fuel ratio, that is, the combustion effect of the combustion-supporting air and fuel under the condition of the air-fuel ratio. The combustion effect does not include the effect of combustion caused by the air intake outside the glass melting furnace. Although the air intake outside the glass melting furnace may cause partial or complete combustion, compared with the combustion system based on the air-fuel ratio, due to the The intake of external air is cold air, which will cause heat loss, so it still has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com