Gearbox rear shell casting method

A rear shell and gearbox technology, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, can solve the problems of low casting efficiency, shrinkage cavity, crack penetration, etc., to meet the performance requirements of castings, reduce Effects of casting defects and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

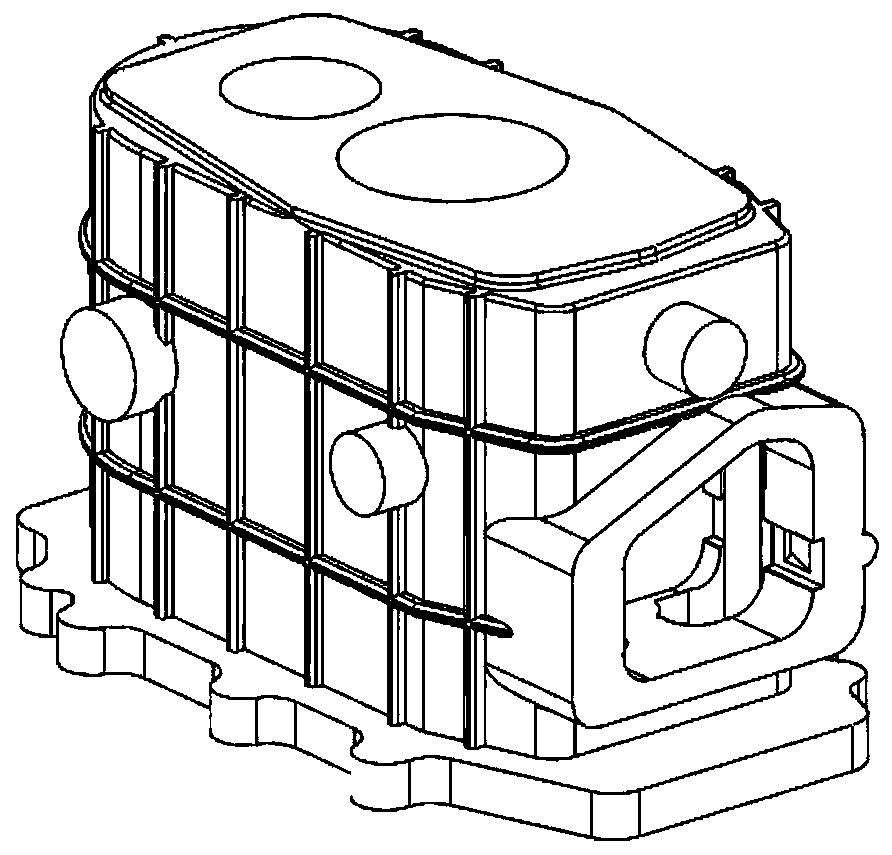

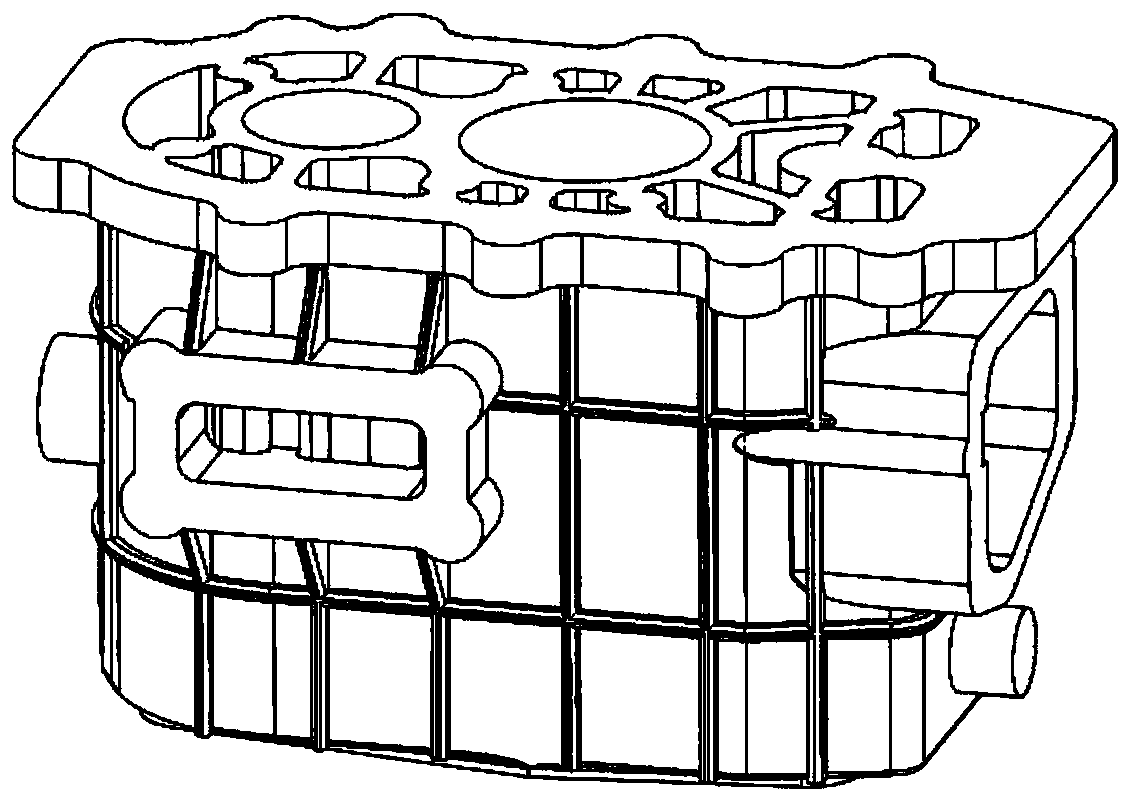

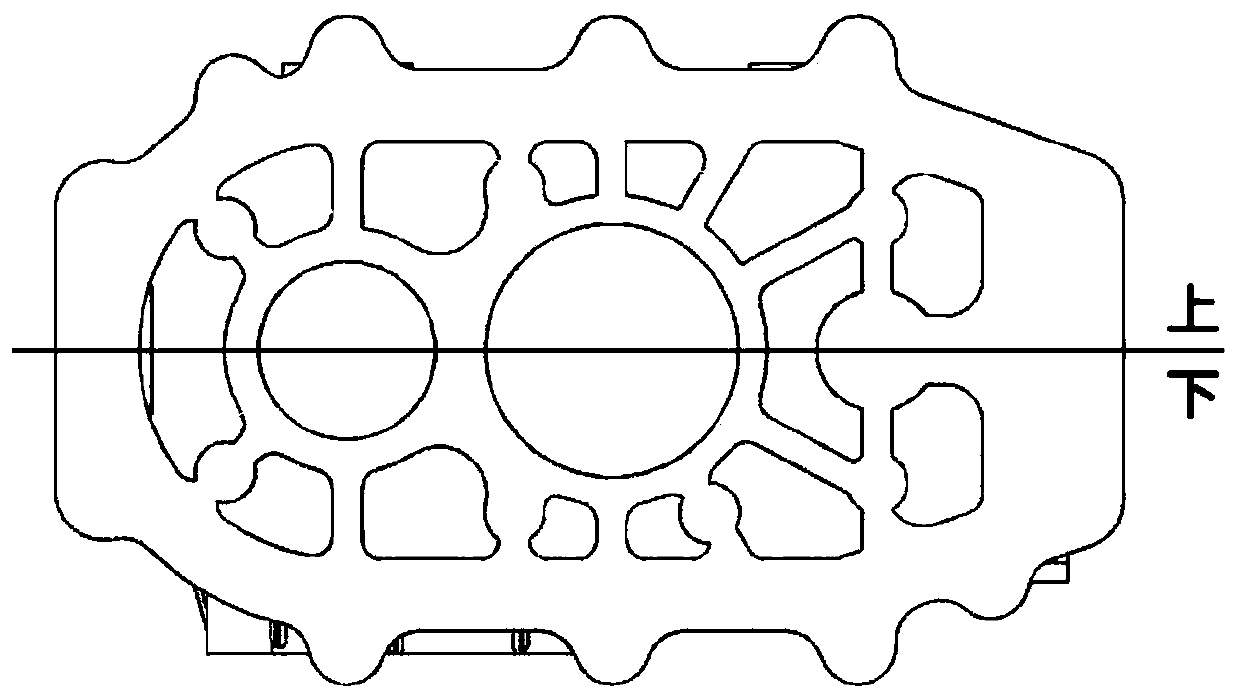

[0032] Embodiment 1: as figure 1 - As shown in 6, a method for casting the rear housing of a gearbox, the method includes the following steps:

[0033] The first step, the selection of molding materials: resin sand is used as the molding material because of its good fluidity, easy compaction, good strength and easy collapse. Considering that gray iron castings are prone to porosity and pinhole casting defects, which will affect the quality of castings, the molding sand should have a small amount of gas generation. Resin sand should be used as the molding material, and alkaline phenolic resin self-setting sand and alkaline phenolic resin should be used. The composition of resin no-bake sand is as follows: the old sand in the molding sand is 40% to 65%, the new sand is 35% to 60%, the resin is 1.5% to 1.7%, the curing agent (resin %) is 30%, and the tensile strength is 0.4% to 0.7%; 60% to 70% of old sand in core sand, 30% to 40% of new sand, 1.7% to 2.0% of resin, 30% of curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com