Mould for continuous casting metal

A crystallizer and metal technology, applied in the field of crystallizers, can solve problems such as insufficient consideration of heat flow distribution, and achieve the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

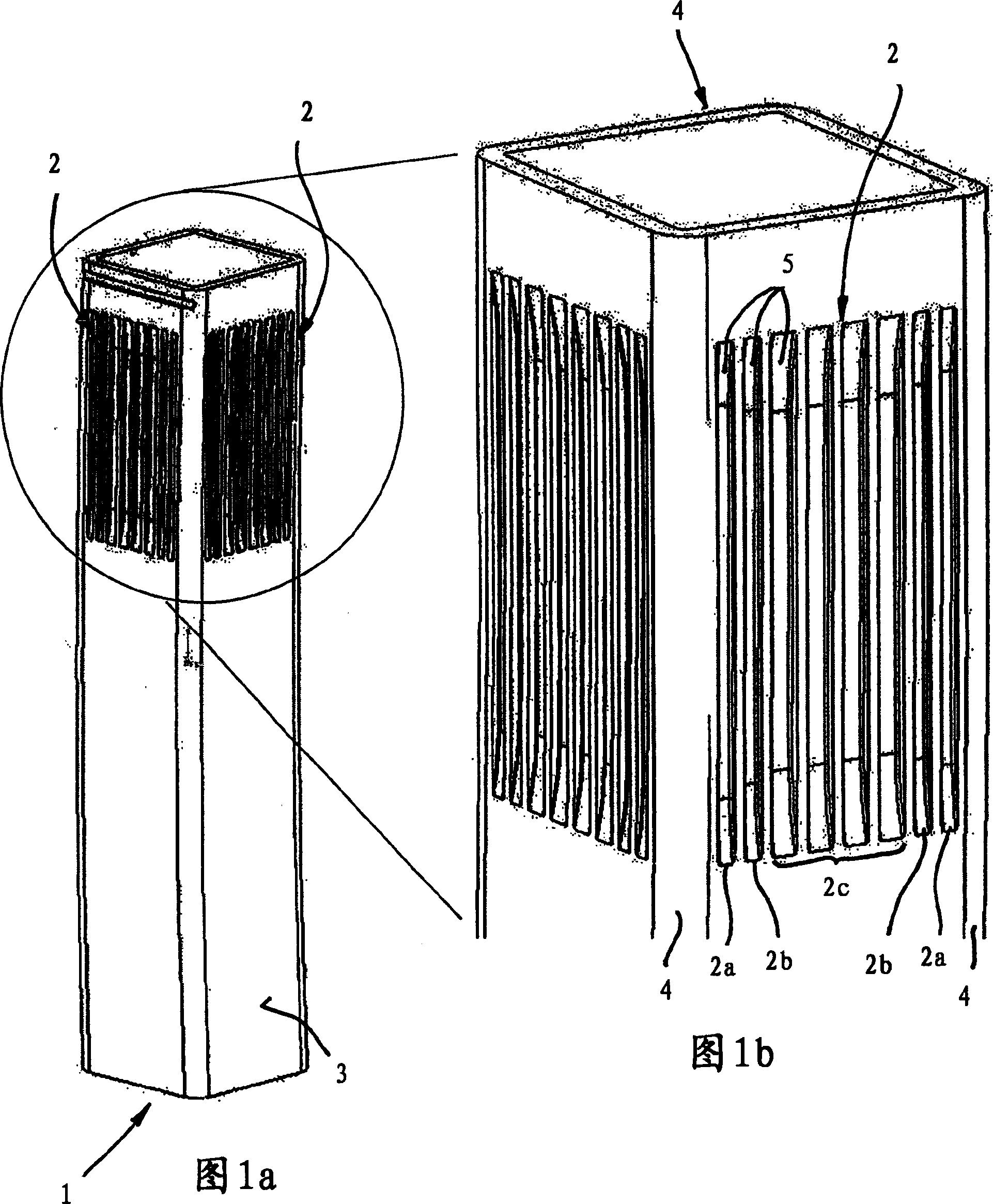

[0019] FIGS. 1 a and 1 b show a perspective view and an enlarged perspective view of a tubular crystallizer 1 , which is positioned in a tank in a manner not described in detail. Special features in this tubular crystallizer 1 are specially designed cooling channels 2 , which are formed on the outer surface 3 of the tubular crystallizer 1 . The cooling channels 2 do not extend over the entire length of the tubular crystallizer 1 , but are only present in the region of the upper injection side of the tubular crystallizer 1 . In this embodiment, the length of the cooling groove 2 is 200mm. The cooling trough 2 is present in the region of the set point of the fill level, the set point of the fill level being in the upper quarter of the cooling trough 2 described. The peculiarity in the cooling channels 2 of the tubular mold is that they are not all of the same width and depth, but are different in width and depth. In the present exemplary embodiment, the outer cooling grooves 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com